SECTION 6-B – 1959 BUICK REAR AXLE SERVICE PROCEDURES

6-4 REMOVAL AND INSTALLATION OF 1959 BUICK REAR AXLE ASSEMBLY

It is not necessary to remove the 1959 Buick rear axle assembly for repair or replacement of a strut rod, an axle shaft, a wheel bearing, or a wheel bearing seal ; however, the 1959 Buick rear axle assembly should be removed for any other repairs.

Removal of 1959 Buick Rear Axle Assembly

- Place car stands solidly under frame so that rear end of car is high enough to permit working underneath and place a floor jack under center of axle housing so it just supports weight of 1959 Buick rear axle assembly.

- Disconnect lower ends of rear springs. On air ride cars, disconnect height control valve link. Pull valve lever down carefully to exhaust all air pressure from air springs. Then remove bolts holding each bearing plate to 1959 Buick rear axle housing and remove plunger and bearing plate assembly.

- Disconnect track bar at axle end. CAUTION: On air ride cars, never disconnect track bar or torque tube unless all air pressure is exhausted from air springs.

- Disconnect lower ends of rear shock absorbers.

- Disconnect parking brake cable at rear cable sheave and at bracket on torque tube. Disconnect brake hose from pipe at torque tube bracket and remove yoke. Cover hose and brake pipe openings to prevent entrance of dirt.

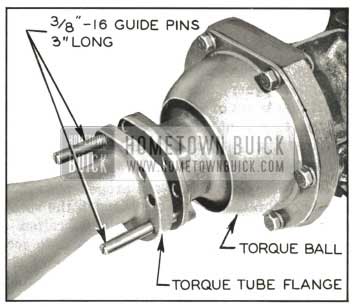

- Remove two opposite torque tube flange bolts, replacing them with two 3″ guide pins. Remove other flange bolts. See Figure 6-3.

1959 Buick Removing Torque Tube from Torque Ball

- Roll 1959 Buick rear axle assembly out from under car.

Installation of 1959 Buick Rear Axle Assembly

The driven yoke of the universal joint fluctuates in speed as torque is being transmitted through the joint. In other words, although the driving yoke rotates at a constant speed, the driven yoke speeds up and slows down twice per revolution. With only one universal joint, the effect of this velocity fluctuation isn’t noticeable. However, with two universal joints, a serious vibration will be set up if the joints are not properly aligned in relation to each other.

To eliminate this condition, the forward end of the front propeller shaft and the rear yoke of the front universal joint each have two blind splines 180° apart. The two propeller shaft blind splines must be carefully aligned with the two universal joint blind splines or the propeller shaft will not slide into the universal joint. This insures that the 1959 Buick rear axle cannot be installed unless the two universal joints are properly aligned. See Figure 4-14 for these blind splines.

- Check torque ball for evidence of oil leaking and for wear of universal joint bushing. If torque ball needs repair or replacement, see paragraph 4-12.

- Check propeller shaft seal for oil leaks or damage. Install a new seal and O-ring if necessary. Seal should be installed in torque tube flange with O-ring over seal O.D.

- Rest car solidly on stands placed under frame, with rear end of car high enough to permit working underneath. Roll 1959 Buick rear axle assembly under car.

- Carefully move axle assembly into place, guiding propeller shaft and torque tube into proper alignment with torque ball using two 3″ guide pins to avoid damage to propeller shaft seal. Rotate rear wheel to align propeller shaft and universal joint blind splines. See figure 4-14.

- Connect torque tube to torque ball, tightening bolts to 50 ft. lbs.

- Connect rear springs to 1959 Buick rear axle assembly. On air ride cars, engage plungers with air spring diaphragms, and install bearing plate to rear axle housing bolts. Carefully push up on height control valve lever to partially inflate air springs and thereby retain plungers.

- Connect shock absorber and track bar lower ends loosely to axle.

- Connect brake hose to brake pipe at torque tube bracket and lock in place with yoke. Connect parking brake cable through bracket on torque tube and to brake cable sheave. Bleed rear wheel cylinders and adjust parking brake as described- in paragraphs 9-7 and 9-9.

- Lower car on wheel stands. Then tighten shock absorber lower ends, and track bar lower end. NOTE: Normal weight must be on rear wheels when tightening these parts so that rubber bushings will be clamped in neutral position.

- Lower car to floor. Fill axle housing to filler plug hole using approved gear lubricant.

6-5 REPLACEMENT OF 1959 BUICK REAR AXLE STRUT ROD

The rear ends of the strut rods are attached to the axle housing by nuts. The front ends of both strut rods are bolted through rubber compression bushings to a bracket welded on the torque tube. Strut rods may be replaced without removing 1959 Buick rear axle assembly. When installing a strut rod, always tighten the mounting bolt at the front end first to allow the elongated hole in the rear end to slide to normal position.

CAUTION: When a strut rod is damaged, there is a good possibility that the 1959 Buick rear axle housing is sprung.

6-6 REPLACEMENT OF 1959 BUICK REAR AXLE SHAFT, WHEEL BEARING, OR OIL SEAL

Removal of 1959 Buick Rear Axle Shaft Assembly

- Place car stands solidly under 1959 Buick rear axle housing so that wheels are clear of floor.

- Remove rear wheel and brake drum.

- Remove nuts holding wheel bearing retainer plate to brake backing plate, leaving bolts in place to support backing plate.

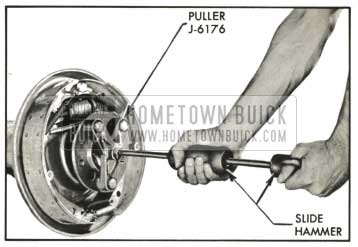

- Pull out axle assembly using Puller J-6176 with a slide hammer. Be careful not to disturb brake backing plate. See Figure 6-4.

1959 Buick Removing Rear Axle Shaft

- Replace two opposite nuts finger tight to hold brake backing plate in position.

Replacement of 1959 Buick Wheel Bearing or Oil Seal

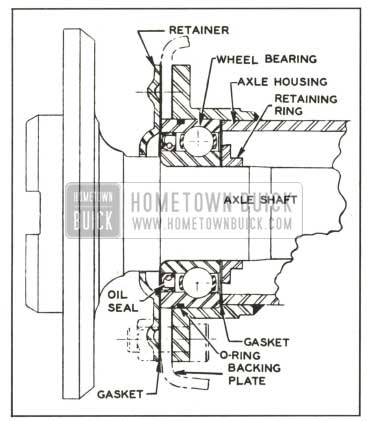

The oil seal is located on the outer side of the bearing between the inner and outer races of the 1959 Buick wheel bearing.

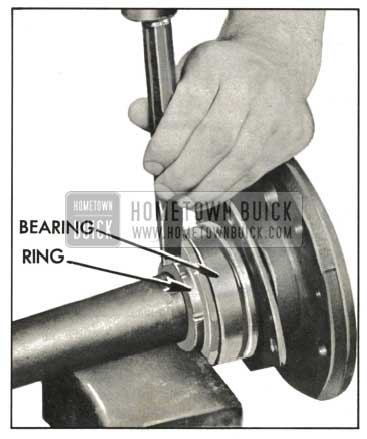

- Nick the wheel bearing retaining ring. NOTE : The ring need not be completely split, but nicked deep enough in 3 or 4 places to spread it. Retaining ring will then slip off with light pressure. See Figure 6-5.

1959 Buick Removing Roar Wheel Bearing Retainer Ring

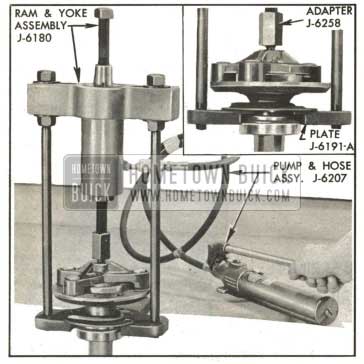

- Press the wheel bearing off, using Plate J-6191-A either in a press or in a set-up using Ram and Yoke Assembly J-6180 and Adapter J-6258 as shown in figure 6-6.

1959 Buick Removing Rear Wheel Bearing

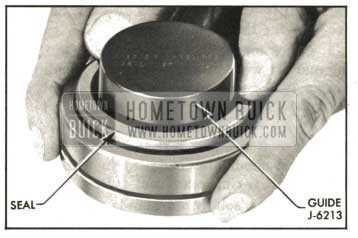

- If seal only is defective, pry old seal from bearing. Examine seal lip surface of bearing for smoothness, then install new seal using Guide J-6213. Push seal in carefully with fingers until lip is over bearing inner race; then remove installing guide and drive seal in flush with a flat wood block. See Figure 6-7.

1959 Buick Installing Rear Wheel Bearing Oil Seal

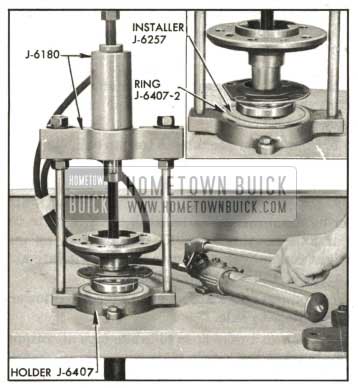

- Press bearing and seal assembly against shoulder on axle shaft using Installer J-6257 either in a press or in a set-up using Ram and Yoke Assembly J-6180 and Holder J-6407 with Ring J-6407-2 shown in figure 6-8.

1959 Buick Installing Rear Wheel Bearing or Retaining Ring

- NOTE: Bearing retainer plate must be on axle shaft before bearing is installed.

- Press retaining ring against bearing with chamfer toward bearing.

Installation of 1959 Buick Rear Axle Shaft

1959 Buick ear axle shafts are not interchangeable between sides; the right shaft is longer than the left.

- Install new gasket at bearing shoulder in housing. Also install new O-ring seal in groove around outside of bearing. See Figure 6-9.

1959 Buick Axle Shaft and Bearing Assembly

- If wheel bearing or seal are only new parts used, replace old wheel bearing retainer gaskets with same number and thickness of new gaskets. Make sure that bearing surface at inner end of axle shaft is lubricated with hypoid gear lubricant.

- If new rear axle housing or new brake backing plate are used, install axle shaft and bearing assembly without retainer gaskets. Using slide hammer and Puller J-6176, drive axle shaft and bearing in place until bearing is fully seated. To hold the retainer plate snug against the face of the bearing, install the four (4) nuts and tighten finger tight.

- With the brake backing plate pushed tight against the housing flange, measure clearance between retainer and backing plate with feelers. Use two feeler gauges at the same time at opposite sides of the retainer plate to prevent any error caused by tipping of the backing plate; Average the two readings so obtained and select the number of new gaskets as required to give .005″ to .020″ less thickness than the average of the two feeler measurements. This adjustment must be made carefully to be sure that wheel bearing inner gasket is held tightly ‘against its shoulder by the wheel bearing. A loose fit here may allow gear oil to leak around the bearing outer race.

- Install nuts holding wheel bearing retainer plate to brake backing plate and tighten to 65-75 ft. lbs. Then check with a .001″ feeler gauge under retainer plate between two lower bolts. If a gap exists between the two lower bolts, remove plate and apply non-hardening sealing compound on both sides of gasket to prevent any possible leak from draining into the brake.

- Replace 1959 Buick brake drum and rear wheel.

- Remove car from stands ; then check to be sure that gear oil level is at filler plug opening.

6-7 REMOVAL OF 1959 BUICK TORQUE TUBES, PROPELLER SHAFTS, AND CARRIER ASSEMBLY

Removal of 1959 Buick Front Torque Tube and Propeller Shafts

- Remove 1959 Buick rear axle assembly from car (par. 6-4).

- Place axle assembly on suitable stands.

- Disconnect torque tube and strut rod brake lines from tee fitting.

- Disconnect strut rods from torque tube bracket. Fasten the two strut rod ends to each other loosely, keeping all parts in their original positions.

- Remove front torque tube to rear torque tube bolts and nuts. Slide front torque tube and propeller shaft assembly from rear torque tube. Slide propeller shaft from front torque tube, being careful that seal surface is not scratched during operation.

- If any part of propeller shaft assembly needs repair, drive spring pin out and separate front and rear propeller shafts.

- Move stand so it will support the strut rods midway.

CAUTION: The strut rods are easily bent while disconnected from the torque tube.

Removal of Carrier Assembly

- Remove 1959 Buick rear axle assembly from car (par. 6-4).

- Place axle assembly on suitable stands and remove front torque tube and propeller shafts as described in par. 6-7, (a).

- Remove both 1959 Buick axle shaft assemblies (par. 6-6).

- Rotate axle housing so carrier is upward.

- Remove rear torque tube to carrier bolts, then remove rear torque tube.

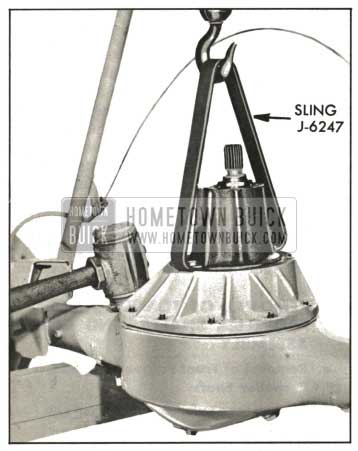

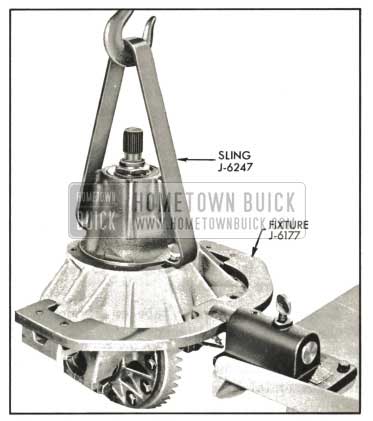

- Remove carrier to axle housing nuts and lift carrier from housing using Sling J-6247 and a chain hoist, if available. See Figure 6-10.

1959 Buick Removing Carrier Assembly from Rear Axle Housing

6-8 CLEANING AND INSPECTION OF 1959 BUICK REAR AXLE PARTS

Cleaning 1959 Buick Rear Axle Parts

Hypoid lubricant combines readily with water and even a small amount of water has a deteriorating effect on the lubricant. For this reason steam or water should not be used for cleaning 1959 Buick rear axle parts.

Gasoline, kerosene, or other solvents are satisfactory for cleaning parts when removed from 1959 Buick rear axle housing, if parts are thoroughly dried before installation. No solvent should be used in an assembled 1959 Buick rear axle, however, because if all traces of the cleaner are not removed, the fresh lubricant will be contaminated. If the rear axle needs cleaning, it must be removed from the car and disassembled.

Wash all disassembled parts in clean solvent and wipe with clean, dry cloths. Vapor degreasers must not be used on painted parts, seals or bearings. Finish drying with clean dry air blast. Do not spin bearings.

Inspection of 1959 Buick Rear Axle Parts

- Thoroughly inspect rear wheel bearing for rust, binding, or excessive looseness as shown under Bearing Service (par. 1-10).

- Propeller Shafts. Check for wear of splines. Splines must be a snug slip fit when assembled. These splines are designed to give slight angular freedom but must not have excessive backlash. Check rear universal joint for wear or excessive looseness.

- 1959 Buick Rear Axle Housing and Torque Tubes. A sprung housing or torque tube should be replaced; straightening is not recommended. These parts must never be heated with a torch for straightening as this may produce distortion of machined bores or soft spots in the metal in which fatigue and breakage may develop in service. Inspect carefully for cracks, especially at welds.

6-9 DISASSEMBLY AND ASSEMBLY OF 1959 BUICK REAR UNIVERSAL JOINT

Because the 1959 Buick rear universal joint is completely protected from road dirt and splash by the torque tubes, and the lubricant is held in each bearing by a packing, no additional lubrication is necessary during the life of the universal joint.

A noisy or excessively worn rear universal joint may be repaired by installing a kit.

Disassembly of 1959 Buick Rear Universal Joint

- Remove snap rings from round bearings using a punch.

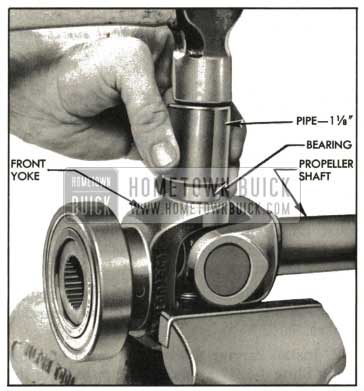

- Lay rear propeller shaft assembly on vise so that yoke welded to shaft bears against open jaws of vise. Shaft should be horizontal and front yoke must be free to move vertically between jaws of vise. See figure 6-11.

1959 Buick Removing Bearing from Front Yoke

- Using a piece of pipe or similar tool having a diameter large enough to encircle bearing (slightly larger than 1 1/8 inch), apply force on front yoke around bearing. Drive yoke down until bearing projects far enough so that snap ring groove is just visible.

- Rotate shaft assembly 180° and repeat Step 3 to partially remove opposite bearing.

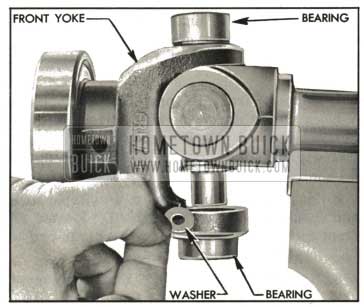

- Now place flat washers (9/16″ O.D.) down in lower end of bearing. See figure 6-12. Total thickness of washers should be 1/8″ to 3/16″.

1959 Buick Placing Washers Inside Front Yoke Bearing

- Rotate shaft 180° and again apply force around bearing in which washers were installed. This will completely remove bearing from yoke.

- Remove front yoke from spider. Remove remaining bearing using a brass drift.

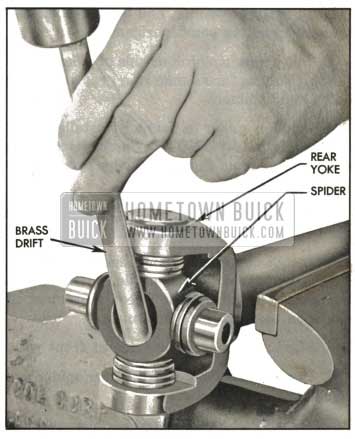

- Clamp or support rear yoke in vise. Drive bearing out until snap ring groove is visible using a drift applied to center part of spider. See figure 6-13.

1959 Buick Removing Bearing from Rear Yoke

- Rotate shaft assembly 180° and repeat Step 8 to partially remove opposite bearing.

- Hold spider up and place flat washers in lower end of bearing. Drive down on spider using a drift until bearing comes out of yoke.

- Remove spider from yoke.

- Drive remaining bearing out using a brass drift.

Assembly of R1959 Buick ear Universal Joint

Make sure each round bearing assembly has a full set of needle rollers (25), has a cork packing and retainer washer, and is well lubricated with high melting point lubricant.

- Drive a bearing in one side of yoke welded to shaft only as far as snap ring groove, using a soft faced hammer.

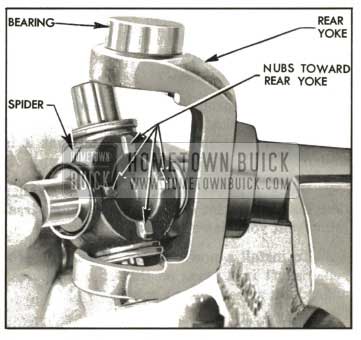

- Position spider in partially installed bearing. See figure 6-14. NOTE: Spider must be installed so locating lugs are facing toward propeller shaft tube.

1959 Buick Installing Spider In Rear Yoke

- Hold spider in place to prevent loss of needle rollers and completely install bearing.

- Install opposite bearing making sure that spider is centered so that needle rollers will not be jammed or dislodged. Check movement of spider in bearings for smoothness.

- Start a bearing in one side of front yoke.

- Position yoke and bearing over spider and completely install bearing.

- Install remaining bearing while spider is centered so that needle rollers are not jammed or dislodged. Check for smooth movement of forward yoke.

- Install snap rings. NOTE: If snap ring cannot be installed on one side, drive bearing toward other side until snap ring groove is clear of yoke.

6-10 REMOVAL AND INSTALLATION OF 1959 BUICK PROPELLER SHAFT BEARING

The 1959 Buick propeller shaft bearing is a sealed ball bearing which is lubricated for the life of the bearing. The bearing should not be removed except to replace it with a new one when noisy, worn or excessively loose.

- With rear propeller shaft separated from front propeller shaft, place rear propeller shaft and bearing assembly in a press so that it is supported under bearing with shaft down.

- Using a sleeve or shaft slightly smaller than inside diameter of bearing, press universal joint front yoke down through bearing.

- To install a new bearing, place rear propeller shaft in a press so that it is supported under both sides of front yoke.

- Start new bearing squarely on yoke. Using a heavy flat plate, press bearing on yoke until it bottoms against shoulder. CAUTION: Be careful that bearing does not cock as .it starts onto yoke.

6-11 INSTALLATION OF 1959 BUICK CARRIER ASSEMBLY, PROPELLER SHAFT AND TORQUE TUBES

Installation of 1959 Buick Carrier Assembly

Before installing the 1959 Buick carrier assembly, the carrier and axle housing mounting surfaces must be clean and free of any old gasket material. Also, make sure these surfaces are free of any burrs or nicks.

- Rotate 1959 Buick axle housing so that carrier mounting surface is upward and install a new carrier gasket.

- Install carrier assembly in axle housing using Sling J-6247 as shown in figure 6-10. Install nuts and tighten them evenly and alternately to 50-60 ft. lbs.

- Install both axle shaft assemblies (par. 6-6).

Checking 1959 Buick Front Propeller Shaft

The 1959 Buick front propeller shaft runs in a definite location due to the fact that it is held in the splines of the rear propeller shaft by a spring pin. If this propeller shaft is handled carefully during removal and installation, it will not normally be necessary to perform a dial indicator check for straightness.

However, if there is a noise or vibration at high speeds which might be caused by a bent shaft (par. 6-3, c), or if there is any possibility that the shaft has been damaged due to rough handling or collision, the propeller shaft should be checked for straightness as follows:

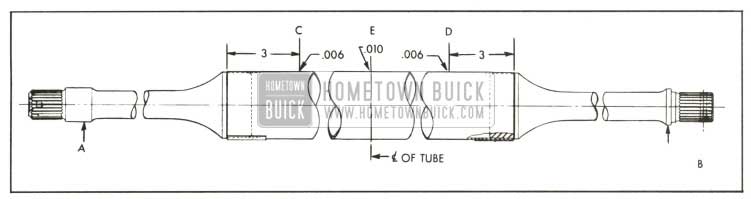

- Support front of propeller shaft on a V-block placed under the seal surface at “A.” Support rear of propeller shaft on a V-block placed under the shoulder at “B.” See figure 6-15.

1959 Buick Front Propeller Shaft Run-Out Specifications

- Mount a dial indicator on a suitable base and check run-out at “C” and “D” located 3″ from each end of tube. Then check run-out at “E” located near center of tube.

- Run-out at “C” and “D” must not exceed .006″; run-out at “E” must not exceed .010″.

However, care must be taken not to include indicator variation due to the shape of the tube in run-out readings. Indicator fluctuation due to ridges, flat spots, or an oval tube must be ignored.

NOTE: If the 1959 Buick propeller shaft is turned rapidly, it is easier to ignore any surface imperfections and to properly locate the high center of a bent propeller shaft.

- If run-out exceeds specifications due to a bent propeller shaft, it is probably more economical to replace the shaft than to attempt straightening it. However, if it is decided to straighten the shaft, mark points of greatest run-out along the length of the tube. By studying these high center marks, the general type and extent of the bend may be readily seen and the straightening procedure planned accordingly.

Straightening 1959 Buick Front Propeller Shaft

In order to straighten a 1959 Buick front propeller shaft, the following tools are necessary; an arbor press, a bending block and two support blocks which are shaped to conform to the tube, and a support which conforms to the seal sleeve shape. This straightening set-up should be near the checking set-up because the shaft must be rechecked after every bend.

The method used in straightening depends on the type of bend. In general, pressure should be applied at the high center of the bend with the shaft supported at both ends of the bend. Then by checking and bending repeatedly, the high center can be brought down until the indicator reading at this point is approximately the same as that at a point 180 degrees opposite. When bending the shaft, use steady pressure and not shock blows to spring the shaft.

Installation of 1959 Buick Propeller Shafts and Torque Tubes

- Check 1959 Buick propeller shaft and pinion splines for excessive wear. Remove any nicks or burrs. Inspect front propeller shaft seal surface for nicks, scratches, or a groove. If badly damaged, front propeller shaft must be replaced. Inspect rear universal joint and support bearing for wear or excessive looseness. A worn joint may be repaired (par. 6-9), but a worn bearing must be replaced.

- Check torque tube flanges and torque tube mounting surface on carrier. Remove any burrs or nicks.

- Install O-ring seal over pinion to a point just past splines. Be careful not to nick or cut seal on splines. Inspect rear propeller shaft seal surface inside rear coupling. Pack coupling with a good grade of chassis grease, bringing level to inner end of splines.

NOTE: It is a good practice to grease all splines before assembling.

- Install rear torque tube on carrier with brake return spring bracket down. (No gasket is used.) Tighten bolts to 50-60 ft. lbs. Rotate axle housing so that rear torque tube extends in a horizontal direction.

- Slide complete propeller shaft assembly into front torque tube until support bearing is seated against shoulder. Be careful of seal surface while sliding propeller shaft into torque tube.

- Push front torque tube and complete propeller shaft assembly into place in rear torque tube. If difficulty is encountered in engaging pinion splines, use Socket J-6192 to rotate propeller shaft.

- Position front torque tube with strut rod bracket down. No gasket is used between front and rear torque tubes, but make sure that bearing retainer plate is in place. Install front to rear torque tube bolts and nuts. Tighten to 65-75 ft.lbs.

- Connect strut rods and tighten bolts to 85-100 ft. lbs.

- Install brake lines on strut rods and torque tube.

- Install 1959 Buick rear axle assembly in car (par. 6-4, b).

6-12 DISASSEMBLY OF 1959 BUICK CARRIER ASSEMBLY

Removal and Disassembly of 1959 Buick Ring Gear and Case Assembly

- Using Sling J-6247, place carrier assembly in suitable mounting fixture such as Fixture J-6177. See Figure 6-16.

1959 Buick Placing Carrier In Holding Fixture

- It is advisable to check the existing gear lash with a dial indicator as described in paragraph 6-13, f. This will indicate gear or bearing wear or an error in backlash or preload setting. It will also enable used gears to be reinstalled at original lash setting to avoid changing gear tooth contact.

- Remove differential bearing pedestal clamp bolts and open pedestals by tapping a wedge in each pedestal slot.

CAUTION: Do not use excessive force on wedges as pedestal bores may be permanently distorted.

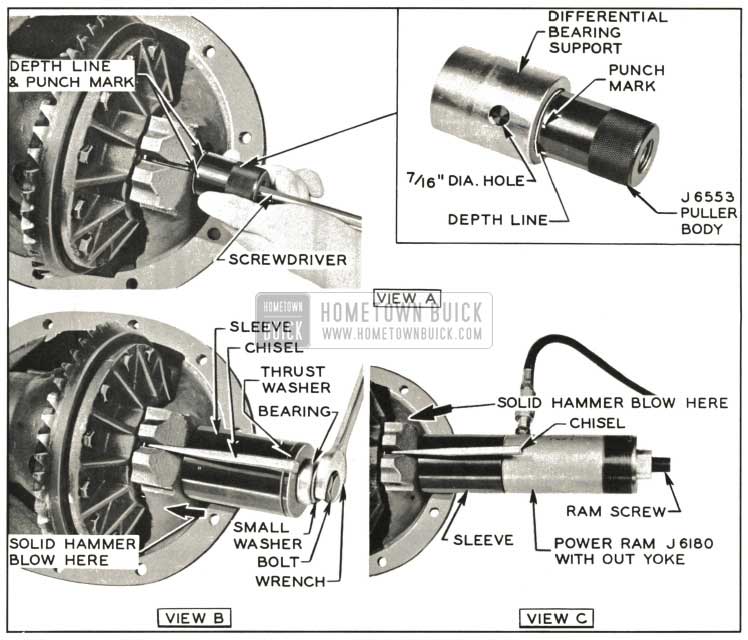

- Pull differential bearing supports with Puller J-6553 using the following procedure:

- Using a screwdriver, turn expanding screw in puller body in a counterclockwise direction to retract pins, then insert puller body into differential bearing support until reference line on tool is flush with end of support and punch mark is in general direction of hole in support. See Figure 6-17, View A.

1959 Buick Removing Differential Bearing Support

- Expand pins a slight amount by turning expanding screw with screwdriver in a clockwise direction until a light drag on pins is felt, then move tool as required to engage pins with holes in support. Fully expand pins.

- Apply a pulling force on bearing support puller by using either of the following methods:

- Place sleeve over puller and install draw bolt with large thrust washer, thrust bearing, and small washer as shown in Figure 6-17, View B; then thread draw bolt in tapped hole in puller body. Using a suitable wrench, apply a reasonable amount of torque to draw bolt; then strike carrier pedestal with a solid hammer blow as shown in Figure 6-17, View B.

- Place sleeve over puller and install hydraulic ram screw as shown in Figure 6-17, View C. Place a reasonable load on ram, then strike carrier pedestal a solid hammer blow in direction of heavy arrow.

- Install Spreader J-6185 shown in figure 6-37. Tighten spreader bolt just enough to free case assembly.

CAUTION: Do not spread pedestals any farther than necessary or they may be permanently sprung.

Lift case straight out until side bearings are half-way clear of pedestals. Then take hold at bearings with both hands to prevent bearings from dropping and lift case assembly out. Keep right and left bearings, shims, and supports in sets so that they may be reinstalled in the same positions. Remove spreader tool.

- Mark ring gear and case, so they may be reassembled in same relative position. Remove ring gear.

- Drive differential pinion axle spring pin, pinion axle and pinion shield from case. Mark side gears, pinions, and washers so they may be reinstalled in same sides. Remove side gears, pinions, and washers.

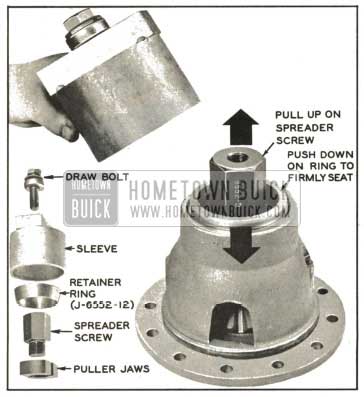

- If a differential bearing is to be replaced, pull bearing outer race from case with Remover J-6552 using the following procedure: (See Figure 6-18)

1959 Buick Removing Differential Bearing Outer Race

- Insert puller jaws with lips down under edge of outer race.

- Carefully thread spreader screw into jaws, making sure that threads are not crossed. Leave spreader screw one full turn away from jaws.

- Place retainer ring over jaws, tapping it down while pulling up spreader screw so that ring fits snugly around jaws, then turn spreader screw tightly against jaws.

- Place sleeve over assembled tool. Insert draw bolt through washer, thrust bearing and sleeve. Then thread it into spreader screw and pull bearing outer race.

Removal of 1959 Buick Pinion and Bearings

- Check pinion pre-load as described in paragraph 6-13. This will indicate excessive bearing wear or an error in pre-load setting.

- It is advisable to check the pinion depth setting as described in paragraph 6-13. This will indicate any error in the existing setting and will also enable used parts to be reinstalled at original setting to avoid changing gear tooth contact.

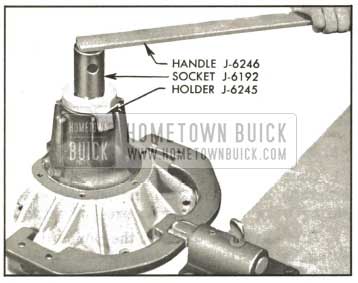

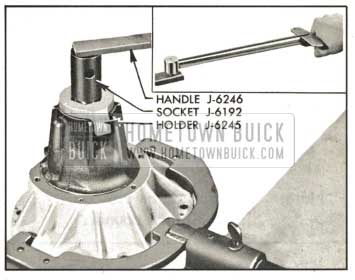

- Cut out and drive up staked section of pinion bearing lock nut with cape chisel, being careful not to damage threads on pinion. Hold pinion nut to carrier with Holder J-6245 and turn pinion clockwise through nut using socket J-6192 and Handle J-6246. See figure 6-19.

1959 Buick Removing Pinion Nut

- As pinion nut is removed, hold hand under pinion to catch it, as it may fall through. Remove pinion nut O-ring seal from pinion. If necessary, tap pinion out with a soft hammer, being careful to guide pinion .with hand to avoid damage to bearing outer races.

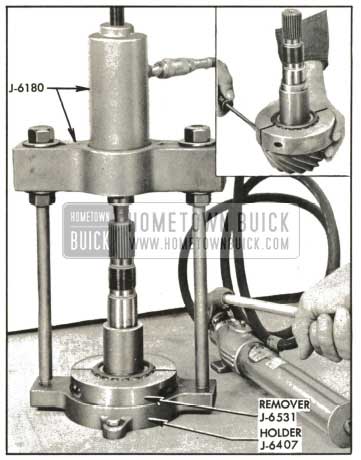

- If rear pinion bearing is to be replaced or pinion depth setting is to be changed, remove rear bearing from pinion shaft using Remover J-6531 and Holder J-6407 in a press or in a set-up using Ram and Yoke Assembly J-6180 as shown in figure 6-20.

1959 Buick Removing Rear Pinion Bearing

- Pry pinion oil seal from carrier, being careful not to damage front pinion bearing. If front pinion bearing is to be replaced, drive outer race from carrier using a drift in slots provided for this purpose.

- If rear pinion bearing is to be replaced, drive outer race from carrier using a drift in slots provided for this purpose.

6-13 ASSEMBLY OF 1959 BUICK CARRIER ASSEMBLY

Installation of 1959 Buick Pinion and Bearings

Before installation of 1959 Buick pinion and bearings make certain that interior of carrier housing is absolutely clean and dry. Also make certain that parts to be assembled are clean and that pinion bearing shims are not burred. Bearings and oil seals should be lightly lubricated with rear axle lubricant just before assembly.

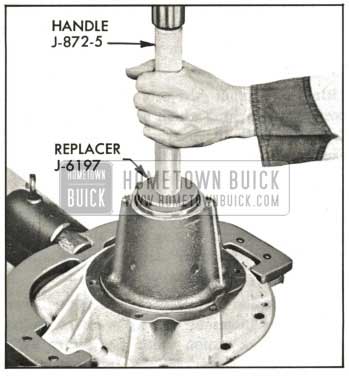

- Drive front pinion bearing outer race against shoulder in carrier using Replacer J-6197 with driver handle. See figure 6-21.

1959 Buick Installing Front Pinion Bearing Outer Race

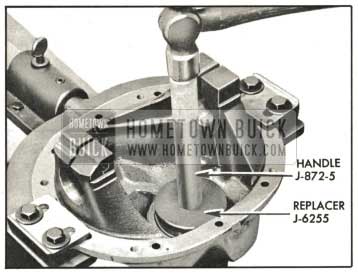

- Drive rear pinion bearing outer race against shoulder in carrier using Replacer J-6255 with driver handle. See figure 6-22.

1959 Buick Installing Rear Pinion Bearing Outer Race

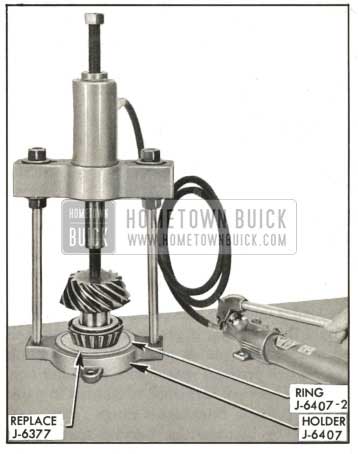

- Whenever a new carrier, a new pinion, or a new pinion bearing is to be used, a trial assembly must be made in order to determine correct pinion depth setting and correct pinion bearing pre-load. For a starting pinion depth setting, use a shim with a nominal thickness of .048″. Place this shim against head of pinion and install rear pinion bearing using Replacer J-6377 and Holder J-6407 with Ring J-6407-2 in a press or as shown in figure 6-23.

1959 Buick Installing Rear Pinion Bearing

- For a starting pinion bearing pre-load adjustment, use a pair of spacers with a nominal thickness of .435″. Place these spacers on pinion and hold pinion assembly in position in carrier. Install front pinion bearing and pinion nut. Hold nut to carrier with Holder J-6245 and turn pinion counterclockwise into nut, using Socket J-6192 and Handle J-6246. Do not install pinion seal at this time. Torque pinion nut to 80 foot pounds using Torque Wrench J-1313 on outer end of Handle J-6246. (This amounts to an actual250 ft. lbs. torque at nut.) See figure 6-24.

1959 Buick Tightening Pinion Nut

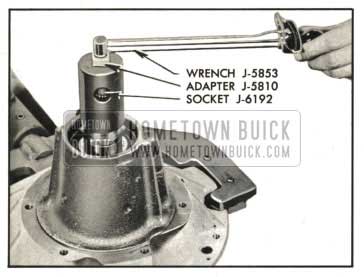

- Rotate pinion three or four times to seat bearings. Turn pinion slowly with an inch pound torque wrench; bearing pre-load should be 10 to 30 inch pounds. See Figure 6-25.

1959 Buick Checking Pinion Bearing Pre-Load

If pre-load is under 10 inch pounds, replace spacer with a thinner one; if pre-load is over 30 inch pounds, remove pinion nut and front bearing and replace pre-load spacer with a thicker one. These spacers are furnished to be used in pairs so that possible thicknesses range from .400″ to .470″ by thousandths. Service spacers are marked with their thickness in thousandths.

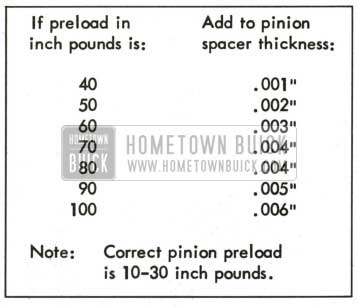

If pre-load is over 30 inch pounds, the approximate number of thousandths to be added to spacer thickness may be determined from the table in Figure 6-26.

1959 Buick Pinion Spacer Thickness Additions

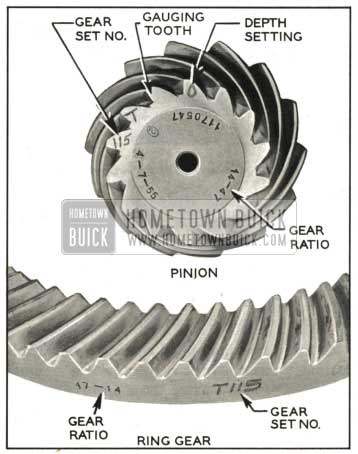

1959 Buick Pinion Setting Marks and Setting Gauges.

All 1959 Buick ring and pinion gear sets are selectively matched for best operating position and proper tooth contact. After matching, a serial number is etched on one tooth of pinion and on rear face of gear to aid in keeping matched parts together. See Figure 6-27. Parts having different serial numbers must never be used together.

1959 Buick Ring and Pinion Gear Set Markings

1959 Buick ring and pinion gear sets are matched in a special test machine which permits adjustment of pinion depth in ring gear until a point is reached where best operation and proper tooth contact under load is obtained. At this point, the setting of the pinion with reference to the centerline of the ring gear is indicated by the machine. This setting may vary slightly from the design or “nominal” setting due to allowable variation in machining the parts.

This variation in thousandths of an inch over or under the “nominal” setting is etched on the small end of a pinion tooth. See figure 6-27.

When a 1959 Buick pinion is marked “+” (plus) it means that the rear face of the pinion when pressed in the carrier must be at the “nominal” distance from the centerline of the side bearing pedestals plus the amount indicated on the pinion tooth. When a pinion is marked “-” (minus) it means that it must be located at the “nominal” distance minus the amount indicated on the pinion tooth.

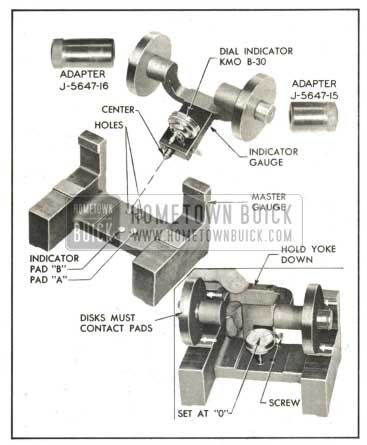

The dial indicator type Pinion Setting Gauge J-5647 is used with adapters to provide a fast and accurate method of checking pinion location; it gives a direct reading on a dial indicator that does not require computation or reference tables. See figure 6-28.

1959 Buick Pinion Setting Gauge J-5647 and Adapters

Before checking the 1959 Buick pinion setting, pinion bearing pre-load must be right because incorrect pre-load will cause a false pinion depth reading.

Checking 1959 Buick Pinion Setting

Pinion Setting Gauge J-5647 consists of a “master gauge” and an “indicator gauge” upon which a dial indicator is mounted. Adapter Set J-5647-17 is not used when “zeroing the gauge,” but is used in place of the discs when checking the pinion setting. See figure 6-28.

- Make certain that the gauge parts are clean, particularly the center and discs of indicator gauge, the centering holes, indicator pads, disc pads on the master gauge, and the adapter holes and outer surfaces.

- Install the discs on the “indicator gauge” and install the small contact button on the stem of the dial indicator. Mount the dial indicator on the indicator gauge. See figure 6-28.

- Place indicator gauge on the master gauge so that the spring loaded center is engaged in the centering hole corresponding to the indicator pad “B,” which is used for any of the following gear ratios stamped on pinion: 43-12 (3.58 to 1), 47-14 (3.36 to 1), 42-13 (3.23 to 1), 43-14 (3.07 to 1), 39-14 (2.78 to 1).

NOTE: Pad “A” is used for certain prior model gear ratios.

- Center the indicator contact button on the specified indicator pad and lock the indicator by tightening the thumb screw.

- Hold yoke down firmly, with both discs contacting the horizontal and vertical pads on master gauge, and set the dial indicator at zero (“0”) .

- Make sure that differential bearing support bores are free of burrs and that the center of the pinion is clean.

- Rotate the pinion until the blank tooth between the matching number and the pinion setting mark is slightly counterclockwise of top center (at about 11 o’clock). This tooth is called the gauging tooth (Fig. 6-27) because it is used for locating and gauging during production and should therefore be used for gauging in service.

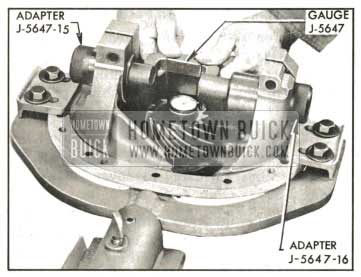

- Drive a wedge into each pedestal split and spread them just enough so that Adapters J-5647-17 will slip in. Then place the indicator gauge in the carrier as follows: (see figure 6-29).

1959 Buick Checking Pinion Setting

- Remove discs from indicator gauge and hold it in position in the carrier with pins centered in the pedestal bores.

- Slide long adapter through pedestal bore farthest from pinion and over gauge pin. Then slide short adapter in place on other side.

- Be sure that gauge center is engaged in pinion center and that adapters are against shoulders of gauge. Then remove pedestal wedges.

- Turn pinion if necessary so that indicator contact button has a good contact with gauging tooth of pinion.

- Press gauge yoke firmly downward toward pinion and read dial indicator noting whether it is plus (+) or minus (-) as indicated by arrows on surface of yoke.

CAUTION: This reading does not indicate the thickness of the shim to be used, but only indicates the variation from the “nominal” setting of the gauging face of this pinion.

- Recheck indicator “zero setting” on master gauge with discs to make sure it was not changed in handling.

- If the old ring and pinion gear set is being reinstalled and it has been in use long enough to establish a wear pattern on teeth, the original pinion setting found before removal should be maintained to avoid changing tooth contact.

- If the ring and pinion set is new, or has not been in use long enough to establish a wear pattern on teeth, the dial indicator reading should be within .0015″ of the pinion setting marked on pinion.

- If pinion setting is not as specified, adjust as follows:

Adjustment of 1959 Buick Pinion Position

The 1959 Buick pinion setting is adjusted by changing the thickness of the shim which is located between the rear pinion bearing inner race and the head of the pinion. These shims are furnished in thicknesses ranging from .040″ to .070″ by thousandths.

- Remove pinion assembly and press off rear pinion bearing using Remover J-6184 and Holder J-6274. (Par. 6-12, b.)

- Remove shim from pinion, wipe dry and measure its thickness with a micrometer. Service shims are marked with their thickness in thousandths. Measure shim anyway, however, as any slight error here will necessitate pulling pinion and bearing again.

- Increase or decrease thickness of shim as required to obtain proper pinion setting.

If pinion is marked “+8”, but gauge reads “+6″, decrease thickness of shim by .002”. If gauge reads “+10″, increase thickness of shim by .002”.

If pinion is marked “-8”, but gauge reads “-6″, increase the thickness of shim by .002”. If gauge reads “-10″, decrease thickness of shim by .002”.

CAUTION: Whenever a new pinion is to be installed, its depth setting must be gauged. Even though the new pinion has the same depth marking, it may require a different thickness shim because the dimension from the gauging face to the bearing shoulder varies in different pinions.

- Change pre-load spacers by same amount that shim thickness was changed. If thickness of shim was decreased .002″, use spacers with .002″ less thickness. If thickness of shim was increased .002″, use spacers measuring .002″ thicker.

- Reinstall rear pinion bearing on pinion with new thickness shim. (Par. 6-13, a.) Install a new pinion nut O-ring seal.

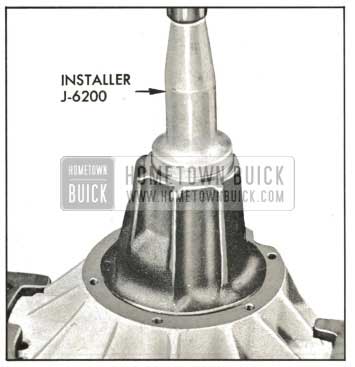

- Lubricate new pinion seal with axle lubricant and install with lip toward bearing, using Installer J-6200. See Figure 6-30.

1959 Buick Installing Pinion Seat

Reinstall pinion and bearings carefully in carrier with new thickness pre-load spacers. Install pinion nut and tighten to 80 foot pounds using Torque Wrench J-1313 in outer end of Handle J-6246 as shown in figure 6-24.

- Recheck pinion setting with gauge. Setting for new pinion must be within .0015″ of setting marked on pinion. Setting for used pinion should be within .0015″ of original setting (as checked before disassembly).

- Recheck pinion bearing pre-load with torque wrench. Pre-load must not exceed 40 inch pounds including drag of lubricated new seal. When pinion pre-load and depth settings are correct, stake pinion nut securely.

Assembly of 1959 Buick Differential Case, Gears and Bearings

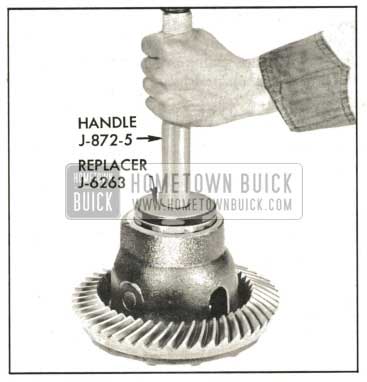

- Drive 1959 Buick differential bearing outer races into case, using Replacer J-6263. See figure 6-31.

1959 Buick Installing Differential Bearing Outer Race

- Install side gears, pinions, and washers in case. If same parts are used, replace in original sides. Install – pinion shield and pinion axle. Drive spring pin through hole in pinion axle until flush with case.

- Check matching numbers on ring gear and pinion to make sure the two parts have not been mixed with another gear set. See figure 6-27.

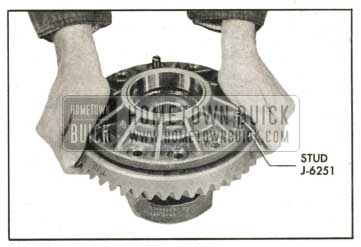

- After making sure that mating surfaces of case and ring gear are clean and free of burrs, bolt ring gear to case using three Studs J-6251 to align parts. See figure 6-32. If same ring gear and case are used, line up marks so they are assembled in same relative positions.

1959 Buick Installing Ring Gear on Differential Case

Do not use lock washers or any substitute bolts.

- First tighten bolts alternately on opposite sides of the case to 25-30 foot pounds torque, then tighten in the same manner to 65-75 foot pounds.

Installation and Adjustment of 1959 Buick Ring Gear and Case Assembly

- Before installation of ring gear and case assembly make sure that differential bearing and bearing support surfaces in carrier pedestals are clean and free of burrs. Remove any burrs which might prevent bearings or bearing supports from seating properly.

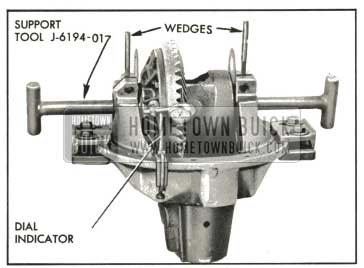

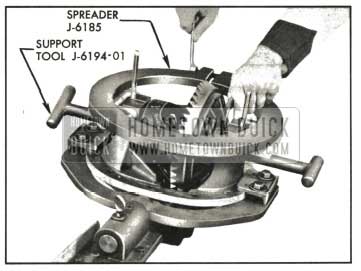

- Place case assembly and differential bearings in position in carrier. If same bearings are used, install in original positions. Insert Support Tools J-6194-01 through the pedestal bores into the bearing inner races. Press tools toward each other to seat them, using hand pressure. If support tools are loose, install pedestal clamp bolts and nuts and tighten lightly until support tools can just be moved by twisting them. If support tools are too tight, loosen them as necessary by slightly wedging pedestals open with chisels. See figure 6-33.

1959 Buick Positioning Differential for Correct Backlash

- Rotate the 1959 Buick differential assembly three or four times to seat bearing rollers, then manually adjust the whole assembly- sideways to get .008″ gear backlash. The assembly tools may be tapped lightly with a hammer to seat them. Check backlash as follows :

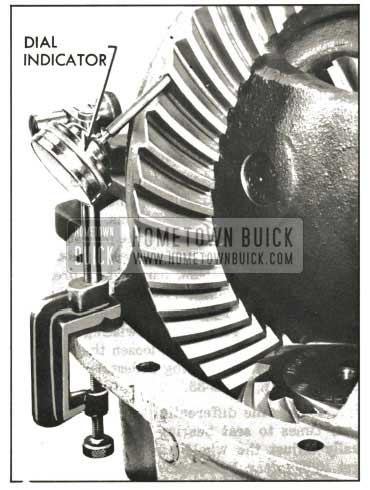

- Mount dial indicator as shown in figure 6-34.

1959 Buick Checking Backlash with Dial Indicator

Use a small button on indicator stem so that contact can be made near heel end of tooth. Set dial indicator so that indicator stem is as nearly as possible in line with gear rotation and perpendicular to the tooth surface. If stem bears against edge of tooth, or stem is at considerable angle to the line of gear rotation, or at a considerable angle to face of the tooth, a false indication of backlash will be obtained.

- Check gear lash at three or four points around ring gear. Lash must not vary more than .003″ around ring gear. If lash varies over .003″ check for burrs, uneven bolting conditions, or distorted case flange, and make necessary corrections.

CAUTION: Any gear lash check must be made with pinion locked to carrier to be sure it cannot turn.- Adjust gear lash at the point of minimum lash to .008″ for all new gears. If original gear set is being reinstalled, the original lash should be maintained.

- Measure with a shim between each bearing and its pedestal. Do not remove support tools for measuring. Select shim that measures .002″ thicker than largest shim that can be inserted for each side; this should pre-load each differential bearing .002″. These shims are furnished to be used singly in thicknesses ranging from .040″ to .082″ by two thousandths. Service shims are marked with their thickness in thousandths.

- Remove support tool farthest from ring gear, insert shim for that side, and replace support tool.

- Place other shim in position for insertion. While keeping a heavy hand pressure on shim, spread carrier pedestals just enough to start shim, using Spreader J-6185.

- CAUTION: Do not spread pedestals any farther apart than is absolutely necessary to push differential shim into position. If pedestals are sprung too far, they may take a permanent set. See figure 6-35. Leave support tool in position until after shim is started to keep case assembly from dropping out of line.

1959 Buick Installing Differential Bearing Shims

- Remove left assembly tool and push shim into final position. Center it first with fingers through pedestal bore, then with a support tool. Remove spreader tool and pedestal wedges.

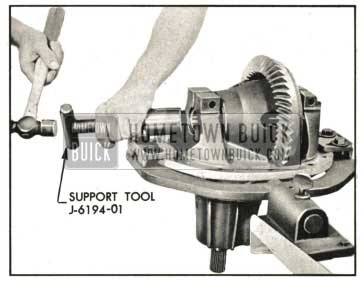

- Lubricate support bushings with hypoid gear lubricant. Drive each differential bearing support into its pedestal until seated solidly in the bearing, using Support Tool J-6194-01. See figure 6-36. Tighten pedestal clamp bolts and nuts to 50-60 foot pounds. Secure nuts with cotter pins.

1959 Buick Installing Differential Bearing Supports

- Recheck backlash as in step 3. Final backlash must be .007″-.009″ at point of minimum lash, with not more than .003″ variation around gear.

Leave A Comment

You must be logged in to post a comment.