SECTION 1-A 1959 BUICK LUBRICARE INSTRUCTIONS

1-1 EVERY 1000 MILES – 1959 BUICK LUBRICARE

- Check engine oil level only after engine has been stopped for at least three to five minutes to allow oil to drain down.

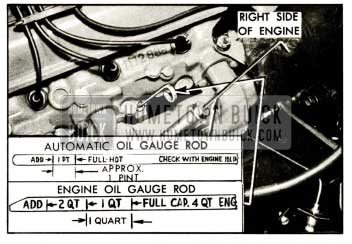

The oil level should be maintained between the “FULL” and “ADD” marks on gauge rod; each space between marks represents 1 quart. Do not fill above the “FULL” mark. See figure 1-5.

1959 Buick Engine and Automatic Transmission Oil Gauge Rods

See paragraph 1-6 for engine oil recommendations and when to change oil.

- Front Suspension, Steering Linkage, Clutch and Rear Propeller Shaft Lubrication Fittings. Wipe dirt from lubrication fittings, then apply a good grade of water resistant chassis lubricant, under pressure, at the following points (fig. 1-2) :

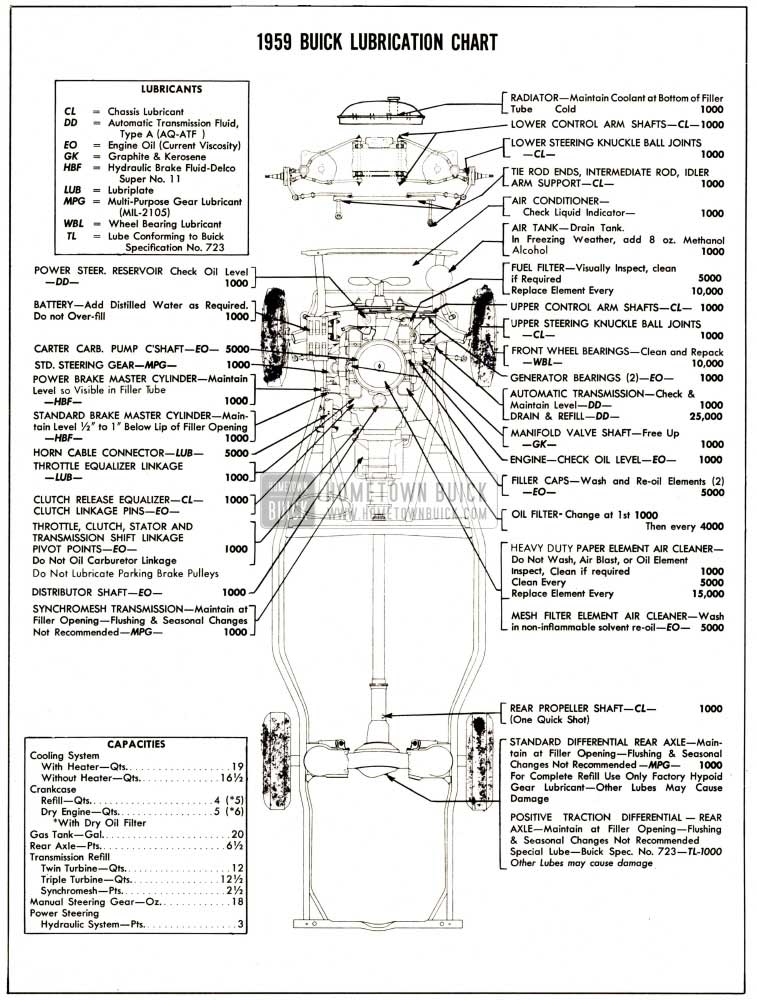

1959 Buick Chassis Lubricare Chart

- Upper Control Arm Shafts (4 fittings)

- Lower Control Arm Shafts ( 4 fittings)

- Upper Ball Joints (2 fittings)

- Lower Ball Joints (2 fittings)

- Tie Rod Ends (2), Intermediate Rod (2), and Idler Arm Support (1)

- Clutch Release Equalizer (1)

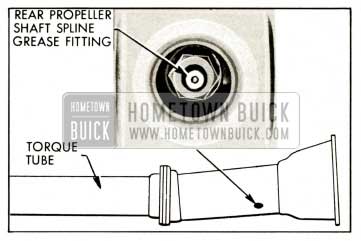

- Rear Propeller Shaft Spline (1) See figure 1-4.

1959 Buick Rear Propeller Shaft Spline Grease Fitting

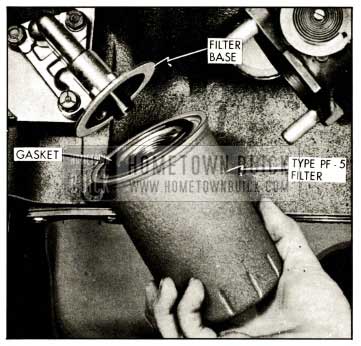

- Oil Filter . Change original oil filter at first 1,000 miles, then change it each 4,000 mile interval thereafter.

Screw filter off filter base and discard. Wipe gasket area of base clean and install new gasket in groove of new AC type PF-5 filter.

Lubricate gasket and screw filter on to stud of filter base hand tight. Start engine. Do not accelerate engine beyond normal idle until oil pressure is indicated. Check filter area for leaks after engine has run for five (5) minutes. See figure 1-1.

1959 Buick Oil Filter Installation

- Synchromesh Transmission. Check oil level, after allowing time for oil to settle. Clean the surrounding area before removing filler plug. Level should be maintained at filler plug opening by adding Multi-Purpose Gear Lubricant (MIL 2105). Use SAE 90 for temperatures not lower than 10°F. below zero; for temperatures continuously lower than -10°F. use SAE 80. NOTE: Draining and flushing transmission is not necessary unless the lubricant has become contaminated.

- Rear Axle

- Standard Differential Rear Axle. Check oil level, after allowing time for oil to settle. Clean the surrounding area before removing filler plug. Level should be maintained at filler plug opening by adding SAE 90 Multi-Purpose Gear Lubricant (MIL-2105). When car is operated in temperatures continuously below -10°F., use SAE 80 Multi-Purpose Gear Lubricant. NOTE: Draining and flushing is not recommended unless the lubricant has become contaminated.

When complete refilling is required use only Factory Hypoid Lubricant as specified in paragraph 1-7. - Positive Traction Differential Rear Axle . Identified by embossed tag on filler plug reading, “Use limited slip differential lube only”. Check lubrication level after allowing time for lubrication to settle. Clean the surrounding area before removing filler plug. Level should be maintained at filler plug opening by adding lubricant conforming to Buick specification #723 only , as specified in paragraph 1-7. See figure 1-3.

- Standard Differential Rear Axle. Check oil level, after allowing time for oil to settle. Clean the surrounding area before removing filler plug. Level should be maintained at filler plug opening by adding SAE 90 Multi-Purpose Gear Lubricant (MIL-2105). When car is operated in temperatures continuously below -10°F., use SAE 80 Multi-Purpose Gear Lubricant. NOTE: Draining and flushing is not recommended unless the lubricant has become contaminated.

1959 Buick Identification of Positive Traction Differential Axle

If oil level is more than one inch below the “FULL” mark on gauge rod, add oil specified in paragraph 1-4 but do not fill above the “FULL” mark. Distance between the “FULL” and “ADD OIL” mark represents approximately one pint.

- Fill oil cup with light engine oil.

- Air Cleaner

- Heavy Duty Dry Type-Normally serviced every 5,000 miles. If car is operating in dusty territory, check condition of air cleaner element and clean if dirty. See instructions in paragraph 1-2.

- Oil Wetted Mesh Type-Normally serviced every 5,000 miles. If car is operating in dusty territory, check condition of element. Wash and re-oil if necessary. See instructions in paragraph 1-2.

- Generator; Fan Belt. Fill front and rear oilers to the caps with light engine oil. Wipe off excess or spilled oil.

Inspect fan belt for cracks and for proper tension. See figure 2-37.

- Check coolant level when engine is cold and add coolant to bottom of filler tube. CAUTION: Radiator cap should not be removed when engine is hot because relieving the pressure may cause the cooling system to boil, with resultant loss of water or anti-freeze solution. Filling radiator above correct level may result in loss of water or anti-freeze solution through overflow pipe.

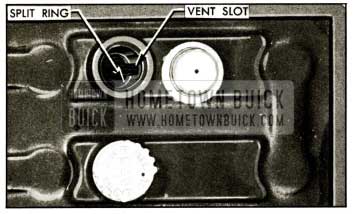

- Add distilled water to bring level to split ring at bottom of filler well. WARNING: Do not overfill. Clean top of battery; if wet with acid, neutralize with soda and wash clean. See figure 1-6.

1959 Buick Battery Filler Well Lubrication

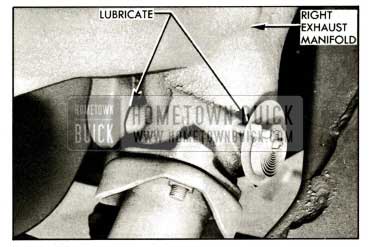

1959 Buick Manifold Valve Lubrication

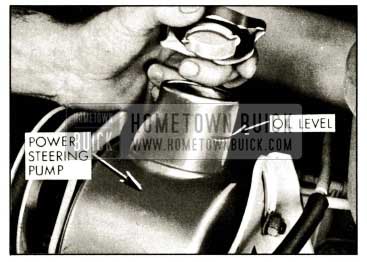

1959 Buick Power Steering Pump Reservoir

Thoroughly clean filler cap nut before removal to avoid getting dirt into reservoir. Add fluid as required to bring level to 1/2″ to 1″ below top of filler opening. Use G.M. or Delco Super No. 11 Hydraulic Brake Fluid. Never use reclaimed fluid or any mineral oil.

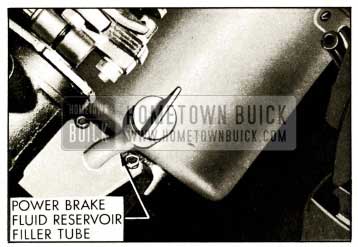

On power brake jobs, the brake master cylinder is mounted on toe board, left side. Level of fluid should be visible in filler tube. Use G.M. or Delco Super No. 11 Hydraulic Brake Fluid. Never use reclaimed fluid or any mineral oil. See figure 1-9.

1959 Buick Power Brake Fluid Reservoir Filler Tube

- Inflate all tires according to tire temperatures, as follows:

- 24 lbs. Starting Pressure-after car has been standing for 3 hours or driven less than one mile. 28 lbs. on Estate wagon rears.

- 26 lbs. City Pressure-after car has been driven 3 miles or more BELOW 40 MPH. 30 lbs. on Estate wagon rears.

- 28 lbs. Highway Pressure-after car has been driven 3 miles ABOVE 40 MPH. 32 lbs. on Estate wagon rears.

WARNING: It is impossible to inflate tires correctly when HOT. Pressure normally increases as tires heat up when driving. Do not deflate tires to offset this increase in pressure.

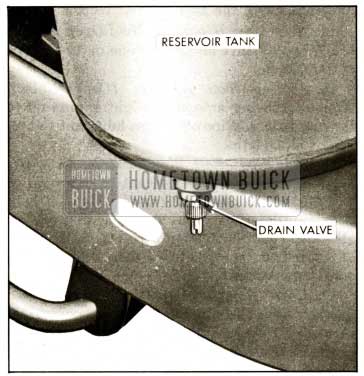

- Air Ride Air Reservoir Tank. Depress drain valve core just enough to allow condensed moisture to be blown out. Valve is located at bottom of tank, right side. See Figure 1-10.

1959 Buick Air Ride Air Reservoir Tank Drain Valve

NOTE: When necessary to drain tank completely for addition of alcohol , time may be saved by raising and lowering the rear of the car to reduce tank pressure ; then removing the drain valve core, allowing the air to escape more rapidly.

1-2 EVERY 5000 MILES – 1959 BUICK LUBRICARE

- Oil Filter. See paragraph 1-1, step 3. (1,000 Mile Lubricare).

- Air Cleaner and Oil Filler Caps.

- Oil Filler Caps. Every 5000 miles (more often under dusty operating conditions) remove the oil filler caps and wash the filtering elements in a non-inflammable solvent. DO NOT USE KEROSENE. Allow elements to drain until dry. Oil the elements and reinstall caps.

- Heavy Duty Dry Element Air Cleaner. For normal operating conditions, remove air cleaner dry element to clean and inspect it every 5000 miles (under dusty operating conditions, every 1000 miles). See figure 1-11.

1959 Buick Heavy Duty Dry Type Air Cleaner Element

To clean element, repeatedly drop squarely on a flat surface from a height of 2 inches until all loose dust has been removed. Turn element over and repeat process. Do not clean by any other method or element will be damaged. Do not wash, air blast , or oil element.

Thoroughly inspect the element visually for any breaks or holes in the fiber. Replace element if any possible dust leaks are found.

Replace element every 15,000 miles with a new AC type A-63-C element on 4 barrel carburetor jobs, or type A-86-C on 2 barrel carburetor jobs. Before installing element, wipe all loose dust from interior of air cleaner. When element and cover are in place, tighten wing nut securely by hand to insure a proper seal on the ends of the element.

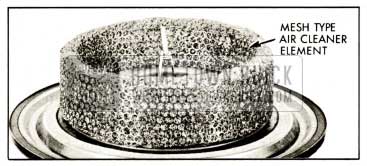

- Oil Wetted Mesh Element Air Cleaner. Every 5,000 miles (more often if car is operated in dusty territory) wash element in noninflammable solvent. DO NOT USE KEROSENE. Allow element to drain dry. Oil element liberally and allow excess to drain off; reinstall. See Figure 1-12.

1959 Buick Oil Wetted Mesh Air Cleaner

NOTE: If an oil wetted mesh type element is re placed with a heavy duty dry type element, care should be taken to thoroughly clean any oil or dirt out of the air cleaner housing before the dry type element is put in service.

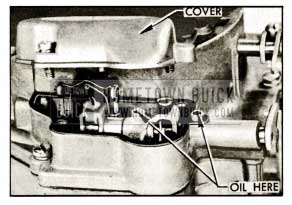

- Pump Operating Countershaft – Carter Carburetor Only. On 2-barrel carburetors, remove dust cover and apply oil in two oil holes above countershaft. See figure 1-13.

1959 Buick Countershaft Lubrication-Carter 2-Barrel

1959 Buick Lubrication of Door Lock

1-3 EVERY 10,000 MILES – 1959 BUICK LUBRICARE

Front Wheel Bearings

At 10,000 mile intervals, the front wheel bearings should be removed, cleaned, repacked with new front wheel bearing grease, and installed as specified in Paragraph 7-10.

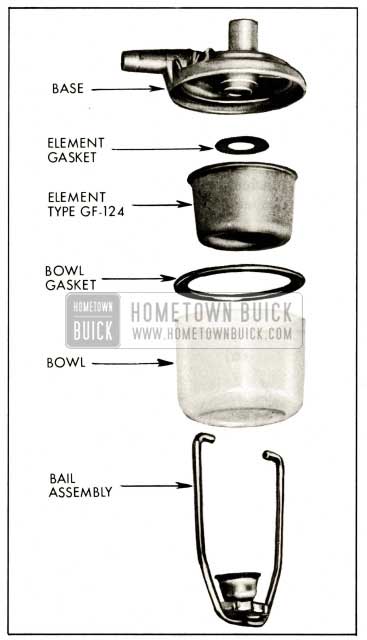

Fuel Filter Element

Each 10,000 miles, remove glass bowl and clean. Soak bowl in a good cleaning solvent to loosen any deposits. Replace element with AC type GF-124 element. Wipe bowl clean and reinstall, tightening bail finger tight. After assembling fuel filter, always start engine and observe filter carefully to make sure gasket is not leaking. See Figure 1-15.

1959 Buick Fuel Filter Exploded View

1-4 EVERY 25,000 MILES – AUTOMATIC TRANSMISSION

At 25,000 mile intervals the transmission should be completely drained, the oil pan and screen should be removed and cleaned, and the transmission should be refilled with fresh oil. Transmission MUST NOT BE FLUSHED when oil is changed.

Approved Oils for Buick Automatic Transmissions

The following oils are approved for Buick Automatic Transmission and no other fluid should be used.

- Special Buick Oil available through Buick Parts Warehouses under Group 4.101.

- Automatic Transmission Fluid, Type A, available through petroleum suppliers. This Figure 1-16-Automatic Transmission Drain Points fluid must have an AQ-ATF number embossed in lid of the can for identification.

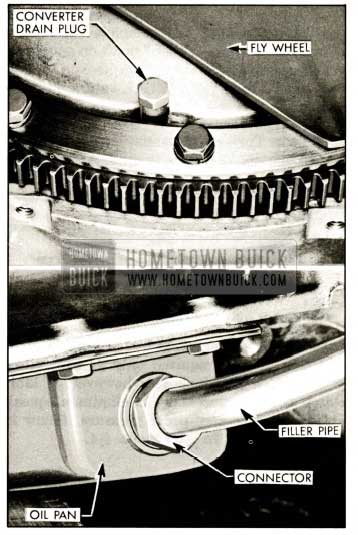

1959 Buick Automatic Transmission Drain Points

Draining and Refilling Automatic Transmission

- Warm up transmission, then remove bell housing cover.

- Loosen one converter drain plug, then turn converter until opposite drain plug is straight down and remove this plug to allow converter to drain completely. See figure 1-16.

- Remove filler pipe fitting from oil pan and allow oil pan to drain completely. Do not remove accumulator caps on Twin Turbine transmission. See figure 1-16.

- Remove oil pan and oil screen, clean thoroughly, and reinstall. Install and tighten drain plugs and filler pipe, then install bell housing cover.

- Put 3 quarts of specified oil (subpar. a.) in transmission. With engine idling and transmission in Parking (P) complete the refilling to bring oil level to “FULL” mark on gauge rod. When transmission oil is warmed up, the oil level should then be at “FULL” mark on gauge rod.

A Twin Turbine transmission refill requires approximately 12 quarts to refill. A Triple Turbine transmission requires approximately 12 1/2 quarts to refill. A completely dry transmission requires an additional 1 3/4 pints.

1-5 1959 BUICK LUBRICARE – AS REQUIRED OR WHEN ACCESSIBLE

1959 Buick Clutch Internal Lubricare

Lubrication of internal working parts of the clutch is usually required only at time clutch is assembled and installed; however, if lubrication becomes necessary to eliminate squeaks or correct excessive pedal pressure, follow instructions given in paragraph 4-4.

1959 Buick Brake Lubricare

Lubrication of all metal contact points at wheel brake assemblies is normally performed during the major brake adjustment or may be performed whenever a brake drum is removed.

Lubrication of parking brake cables is also performed during the major brake adjustment; however, operation under conditions where mud and water are frequently encountered may require more frequent lubrication. See paragraph 9-9.

1959 Buick Rear Wheel Bearing Lubricare

Rear wheel bearings are lubricated by gear lube splash from the differential housing and need no other lubrication. Whenever rear brakes are relined, or drums are removed for other work, it is advisable to inspect for evidence of leaking rear wheel bearing oil seals. Replace seals if leaking.

1959 Buick Speedometer Cable Lubricare

The speedometer cable is factory lubricated with special all-season grease and normally requires no further service unless it becomes noisy. In extremely hot climates or where considerable dirt and water are encountered, however, it may be necessary to lubricate the cable at intervals of approximately 20,000 miles or every two years. See paragraph 10-58.

1959 Buick Sunshade Lubricare

If the sunshade rod turns hard in the support as sunshade is moved up and down, remove retainer screw, pull rod from support and apply stick type lubricant. Do not use oil, which may soil body trim. Install rod in support and adjust retainer screw to proper tension.

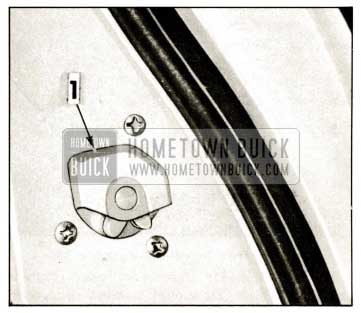

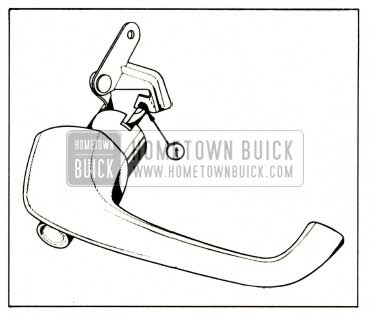

1959 Buick Door Lock Outside Handle

Apply light coat of Lubriplate or its equivalent to surface of lock cylinder shaft contacting the bell crank indicated at “1” in figure 1-17.

1959 Buick Lubrication of Door Outside Handle

1959 Buick Door Lock Parts

Lubricate moving parts of door lock with Lubriplate or its equivalent.

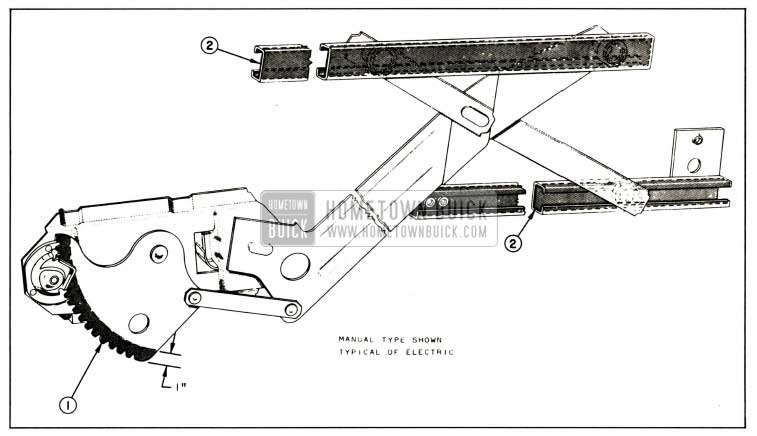

1959 Buick Front and Rear Door Window Regulator Sector and Channels

Apply a coat of Lubriplate or its equivalent to location of regulator sector indicated at “1” and to sliding surface of window cam and guide channels indicated at “2” in figure 1-18. Although the channel and guide assemblies are different on the rear doors, lubrication of the front door parts is typical of lubrication required on rear door parts.

1959 Buick Lubrication of Front and Rear Door Window Regulator and Channels

Seat Regulator Jack Screw (Six-Way Seat)

Thoroughly wipe off old lubricant; then apply Lubriplate or its equivalent to jack screw. Operate seat adjuster to limit of all positions and wipe off excess lubricant.

Rear Compartment Gutter Weatherstrip

Carefully apply a coat of silicone rubber lubricant to surface of gutter weatherstrip and along length of weatherstrip. The weatherstrip should be lubricated whenever the action of the compartment lid is retarded due to friction with the weatherstrip.

Door Locking Mechanism

Apply Lubriplate or its equivalent at pivot joints of inside locking rods as indicated by arrows in figure 1-19.

1959 Buick Lubrication of Door Locking Mechanism

1-6 1959 BUICK ENGINE OIL RECOMMENDATIONS

Choice of 1959 Buick Engine Oil

- Brand of Oil. In the selection of the proper brand of oil it is essential to consider the reputation of the refiner or marketer. It is recommended that the same brand of oil be used at all times.

- Type of Oil. There are several types of oil manufactured for use in internal combustion engines. For use in the Buick engine we recommend that a heavy duty type oil marked “For Service MS” or “For Service DG” be used for maximum protection under all driving conditions. Oils marked “For Service MM” or “For Service ML” are not recommended for any Buick engine.

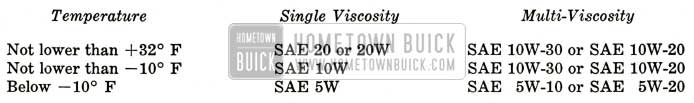

- Grade or Viscosity. The grade or viscosity (SAE number) of engine oil should be selected for the lowest anticipated temperature at which cold engine starting will be required as recommended in the temperature-viscosity chart below.

1959 Buick Temperature-Viscosity Chart

When to Change 1959 Buick Engine Oil

The crankcase should be completely drained and refilled with new oil of proper viscosity at the end of the first 1,000 miles and every 2,000 to 3,000 miles thereafter. Adverse driving conditions require more frequent draining and refilling. Adverse driving conditions are those which may cause early contamination of engine oil, such as operation under unusual dust conditions or short runs with a cold engine.

The color of “Service MS” type oil does not indicate its condition since it normally becomes dark (black or gray) after only a few hundred miles of driving. This is because the detergent content envelopes and holds in suspension extremely fine but harmless soot (soft carbon) and lead particles. The oil filter element does not remove this harmless material but it does remove all harmful particles such as road dust, metal chips and hard carbon.

Engine crankcase oils have a definite effect on ease of starting, oil economy, combustion chamber deposits and engine wear. Many commercial crankcase oils contain heavy nonvolatile deposit forming components which make the type of combustion chamber deposits that greatly increase detonation and particularly pre-ignition, even though these oils may be designated “For Service MS” or “For Service DG.” Some commercial crankcase oils are deficient in anti-wear characteristics and may contribute to rapid wear of camshafts, valve lifter assemblies and other highly stressed engine parts. Owners should be urged to use only crankcase oils that have been proven to produce ease of starting, satisfactory oil economy, minimum combustion chamber deposits and adequate protection against wear.

1959 Buick Crankcase Flushing

Flushing the crankcase with oils or solutions other than a good grade of 10-W engine oil is not recommended. When flushing to remove contamination appears advisable, use 3 quarts 10-W oil (4 quarts if filter is drained) and idle the engine at 1000 RPM (equivalent to 20 MPH) until the oil is hot, then drain crankcase and oil filter immediately after stopping engine. Fill crankcase with correct quantity and seasonal grade of oil.

Use of Buick HD Concentrate

Buick HD Concentrate, available through Buick Parts Department under Group 1.850 is a compound of the materials used by oil refiners to manufacture high detergency motor oils. It is intended for use in engines operating under aggravated conditions where engine deposits, rust and corrosion cannot be adequately retarded by motor oils readily available to the average motorist. It is especially recommended for engines operated under restricted conditions such as frequent stops, short trips and slow speeds where such symptoms as sticking valves, valve lifters and rings are noticed.

Although HD Concentrate may be used continually it is normally unnecessary to use it with every crankcase refill. When used, the instructions on the container should be carefully observed.

1 -7 1959 BUICK REAR AXLE LUBRICANT RECOMMENDATIONS

1959 Buick Standard Differential Axle

Buick standard rear axles are filled at the factory with a special hypoid gear lubricant. It is not necessary to remove the original lubricant at any time except when it has become contaminated, or when it is required for inspection of parts or for repairs. Therefore there is no drain hole in the rear axle housing.

Under no circumstances should the factory lubricant be removed from the rear axle to be replaced with any other type of lubricant.

In all cases of complete refilling of standard rear axle only Factory Hypoid Gear Lubricant is recommended. This is the same lubricant (lead soap-active sulphur type) as furnished with Buick replacement ring and pinion gear sets, and it may be obtained from any Buick Parts Warehouse under Group 5.535.

When adding lubricant to bring it to proper level Factory Hypoid Gear Lubricant is preferred; however, SAE 90 Multi-Purpose Gear Lubricant (MIL-2105) may be added.

In temperatures consistently below -10° F add SAE 80 Multi-purpose gear lubricant.

1959 Buick Positive Traction Differential Axle

1959 Buick Positive Traction Differential Axles are filled at the Factory with a special lubricant conforming to Buick Specification No. 723. It is not necessary to remove the lubricant at any time except when it has become contaminated or when it is required for inspection of parts or for repairs. There is no drain hole in the rear axle housing.

In all cases of adding lubricant to bring to proper level or complete refilling of Positive Traction Rear Axle, only lubricant conforming to Buick Specification No. 723 may be used. Lubricant conforming to this specification may be obtained from any Buick Parts Warehouse under Group 5.535.

Positive Traction Differential Rear Axles can be identified by an embossed tag affixed to the rear axle filler plug which reads, “Use Limited Slip Differential Lube Only”. Also, a letter “X” inside a letter “0” is stamped on the bottom of the differential carrier casting just forward of the rear axle housing and is visible from beneath the car. See figure 1-3.

Leave A Comment

You must be logged in to post a comment.