SECTION 10-D 1959 BUICK GENERATING SYSTEM

10-20 THE 1959 BUICK GENERATING SYSTEM

The 1959 Buick generating system restores to the battery the energy used in cranking the engine. It also supplies current to carry the electrical load of the ignition, lights, signaling devices, and accessories, at operating speeds above 25 MPH up to the limit of the generator’s capacity. At speeds below 25 MPH the output of 1959 Buick generator is not sufficient to carry the electrical load of all units, therefore the battery supplies the additional current required.

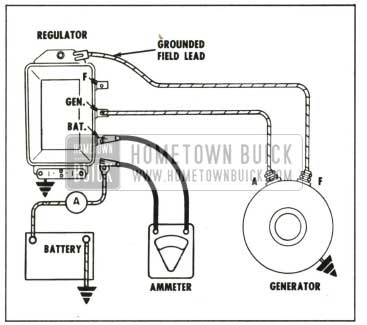

The 1959 Buick generating system consists of the 1959 Buick generator (par. 10-21), 1959 Buick generator regulator (par. 10-22), 1959 Buick charge indicator, 1959 Buick battery (par. 10-14), the 1959 Buick wires and cables connecting these units, and the battery ground cable and ground through engine crankcase which completes the circuit. See figure 10-6.

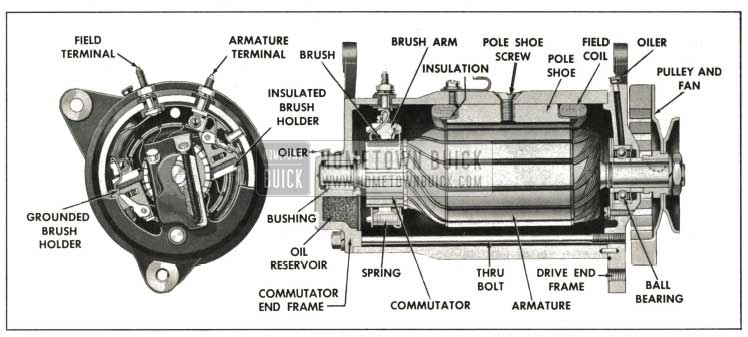

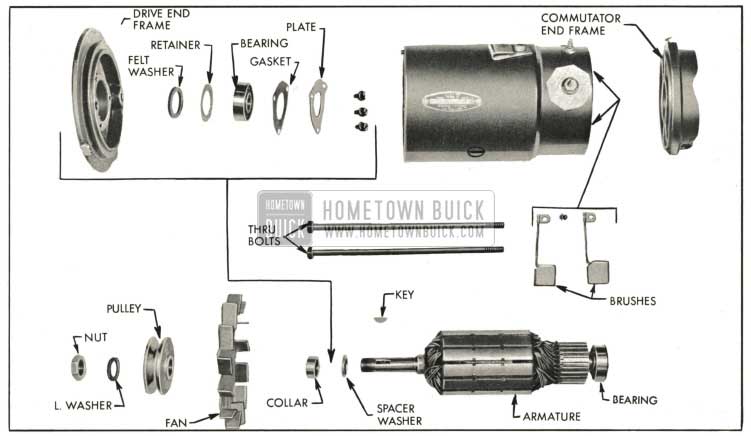

1959 Buick Generator, Sectional View-Standard Car

The charge indicator indicates charging current going into the battery and the current leaving battery, except when cranking the engine. The charge indicator does not indicate total charging rate of 1959 Buick generator since current supplied by generator to electrical units other than the battery does not pass through the indicator.

10-21 DESCRIPTION OF 1959 BUICK GENERATOR

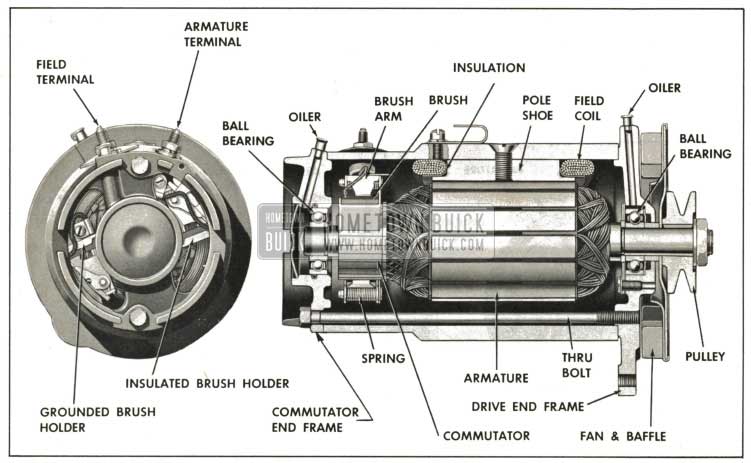

The 1959 Buick generator is a two-brush, two-pole shunt wound unit. The standard generator is capable of delivering 35 amperes at 14 volts. A special generator is used on cars having air conditioners which is capable of delivering 45 amperes. Air conditioner cars also have a special air duct which carries cool air from the area ahead of the radiator and forces it into the commutator end of the 1959 Buick generator.

This additional cooling results in a higher output at low speeds and also safely permits a 5 ampere higher maximum current output over the standard generator having no air duct.

The maximum output of 1959 Buick generator is controlled by the current regulator; however, the 1959 Buick generator does not normally deliver the maximum output because the voltage regulator controls output in accordance with the requirements of the battery and the current consuming units in operation. See figure 10-10.

The 1959 Buick generator pulley drives a fan which draws a draft of air through the 1959 Buick generator to carry away the heat produced during operation. This ventilation permits the generator output to be increased to higher values than would be possible in a non-ventilated generator of the same size. See figure 10-6.

The armature shaft is supported by annular ball bearings in both the drive end frame and the commutator end frame in the air conditioner generator. The standard generator has a ball bearing at the drive end and a bushing at the commutator end. In order to provide this bushing with longer lasting lubrication, it has a wick oiler fed from a large reservoir filled with wool waste. Both 1959 Buick generators are provided with oil cups at each end for periodic filling with engine oil.

The two brushes are mounted in individual brush holders attached to the field frame and are held in contact with the commutator by spring loaded brush arms. One brush holder is grounded to the frame by the attaching rivet. The opposite brush holder is attached to the frame by a rivet and the “A” terminal screw but is completely insulated from the frame. The brush in this holder is connected to the field coils and to the “A” terminal screw. See figure 10-7. Each field coil is held in place by a pole shoe attached to the frame by a large screw, and the coil is separated from its pole shoe by heavy insulation. See figure 10-7.

1959 Buick Generator, Sectional View-Air Conditioned Car

The 1959 Buick generator is mounted on a bracket on right side of engine and is driven by the fan belt. The method of mounting permits generator to be moved in or out to adjust tension of fan belt.

10-22 DESCRIPTION OF 1959 BUICK GENERATOR REGULATOR

The 1959 Buick generator regulator is mounted to the rear of the battery and is cushioned by rubber to dampen the noise which is caused when the regulators operate. The regulator is grounded through two of the attaching bolts, and to insure positive ground the base of regulator is also connected by a wire to the generator frame.

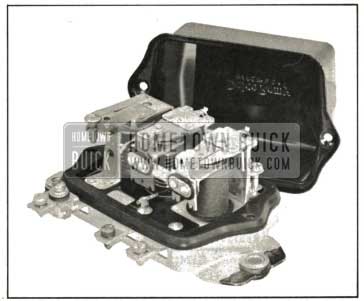

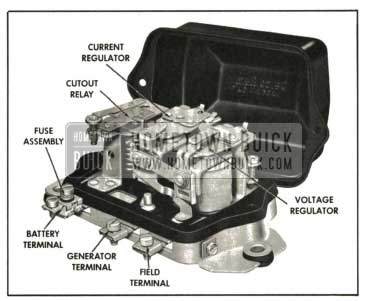

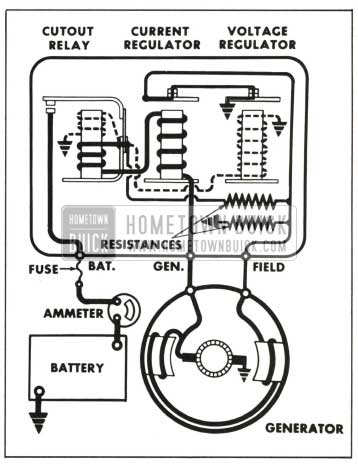

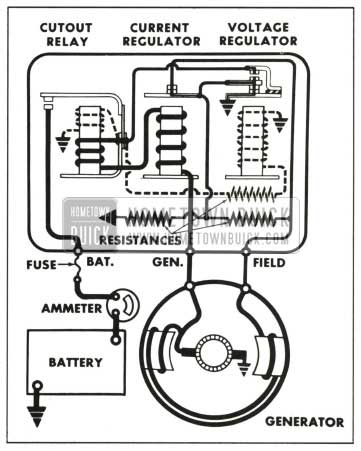

The 1959 Buick generator regulator contains a cutout relay, current regulator, and voltage regulator, all mounted on one base and enclosed by a sheet metal cover. See figure 10-8. These three devices are magnetic switches whose functions and operations are as follows:

1959 Buick Generator Regulator-Standard Car

1959 Buick Generator Regulator-Air Conditioned Car

1959 Buick Cutout Relay

The 1959 Buick cutout relay opens the circuit to prevent the battery from discharging to ground through the 1959 Buick generator whenever the engine is stopped or generator is operating at such low speed that its voltage is less than voltage of battery. When the voltage of generator is slightly greater than battery voltage the relay closes the circuit so that generator can furnish current to the electrical system.

The cutout relay has a series or current winding of a few turns of heavy wire, and a shunt or voltage winding of many turns of fine wire, both assembled on the same core. The shunt winding is connected between generator armature and ground so that 1959 Buick generator voltage is impressed upon it at all times. The series winding is connected so that all generator output current must pass through it. It is connected to a flat steel armature which has a pair of contact points through which current passes to the battery and other electrical units. The contact points are held open by armature spring tension when the unit is not operating. See figures 10-10 and 11.

1959 Buick Generator System Circuits-Standard Car

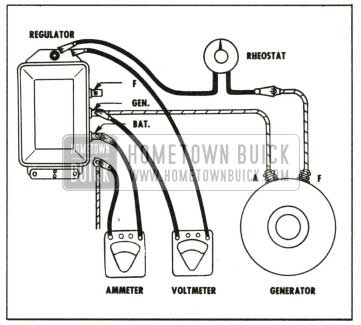

1959 Buick Generator System Circuits-Air Conditioned Car

When the 1959 Buick generator begins to operate, voltage builds up and forces current through the shunt winding, thereby magnetizing the core. When the voltage reaches the value for which the relay is set, the magnetism is strong enough to overcome the armature spring tension and pull the armature toward the core, thereby closing the contact points. Generator current now flows through the series winding of relay in the right direction to add to the magnetism holding the points closed, and passes on to the battery and other electrical units in operation.

When the 1959 Buick generator slows to engine idling speed, or stops, current begins to flow from the battery back through the generator, reversing the current flow through the series winding. This reduces the magnetism of the relay core to the extent that it can no longer hold the contact points closed against armature spring tension. The points are separated and the circuit broken between the generator and battery.

Both standard and air condition regulators have a fuse in the 1959 Buick generator charging circuit. This fuse connects to the battery terminal of the regulator and the battery lead connects to it in turn. The purpose of the fuse is to protect the generator and wiring should a stuck or welded cutout relay occur. Shorts or grounds occurring in the charging circuit or reverse polarity conditions of the 1959 Buick generator can cause the cutout relay points to weld together. This allows the battery to discharge thru the generator when the generator is not developing greater than battery voltage. Since the generator has such low internal resistance, tremendously high current will flow from the battery causing wiring to burn and deterioration of the generator.

1959 Buick Current Regulator

The 1959 Buick current regulator automatically controls the maximum output of the 1959 Buick generator. When the current requirements of the electrical system are large and the battery is low, the current regulator operates to protect the generator from overload by limiting its output to a safe value.

The current regulator has one series winding of heavy wire through which the entire 1959 Buick generator output flows at all times. This winding connects to the series winding in the cutout relay, described above. Above the winding core is an armature, with a pair of contact points which are held together by spring tension when the current regulator is not operating. When current regulator is not operating and the contact points are closed, the 1959 Buick generator field circuit is directly grounded so that generator may produce maximum output, unless further controlled by the voltage regulator described below. See figures 10 and 11.

When the 1959 Buick generator output increases to the value for which the current regulator is set, the magnetism of the current winding is sufficient to overcome the armature spring tension. The armature is pulled toward the winding core so that the points are separated. The 1959 Buick generator field circuit must then pass through a resistance, which reduces the flow through the field coils and thereby reduces the output of generator. This reduces the magnetic strength of the current winding so that spring tension again closes the contact points, directly grounding the generator field circuit and increasing generator output. This cycle is repeated many times a second, and the action limits the generator output to the value for which the regulator is set.

The current regulator has a bi-metal hinge on the armature for thermostatic temperature control. This automatically permits a somewhat higher generator output when the unit is cold, and causes the output to drop off as the temperature increases.

The current regulator operates only when the condition of battery and the load of current-consuming units in operation require maximum output of the 1959 Buick generator. When current requirements are small, the voltage regulator controls generator output. Either the current regulator or the voltage regulator operates at any one time; both regulators never operate at the same time.

1959 Buick Voltage Regulator

The 1959 Buick voltage regulator limits the voltage in the charging circuits to a safe value, thereby controlling the charging rate of the 1959 Buick generator in accordance with the requirements of the battery and the current-consuming electrical units in operation. When the battery is low, the generator output is near maximum but as the battery comes up to charge, and other requirements are small, the voltage regulator operates to limit the voltage, thereby reducing the generator output. This protects the battery from overcharge and the electrical system from high voltage.

The 1959 Buick voltage regulator unit has a shunt winding consisting of many turns of fine wire which is connected across the 1959 Buick generator. The winding and core are assembled into a frame. A flat steel armature is attached to the frame by a flexible hinge so that it is just above the end of the core. When the voltage regulator unit is not operating, the tension of a spiral spring holds the armature away from the core so that a point set is in contact which allows the generator field circuit to complete the ground through them. See figure 10-9.

When the 1959 Buick generator voltage reaches the value for which voltage regulator is set, the magnetic pull of the voltage winding is sufficient to overcome the armature spring tension, so that the armature is pulled toward the core and the contact points are separated. The instant the points separate, the field current flows only through the resistance to ground. This reduces the current flow through the field coils and decreases generator voltage and output.

The reduced voltage in the circuit causes a weakening of the magnetic field of the voltage winding in the regulator. The resulting loss of magnetism permits the spring to pull the armature away from the core and close the contact points again, thereby directly grounding the 1959 Buick generator field so that generator voltage and output increases.

This cycle is repeated many times a second, causing a vibrating action of the armature, and holds the 1959 Buick generator voltage to a constant value. By maintaining a constant voltage, the voltage regulator continues to reduce the 1959 Buick generator output as the battery comes up to charge. When the battery reaches a fully charged condition, the voltage regulator will have reduced the generator output to a relatively few amperes.

For a more detailed explanation of the operation of the double contact voltage regulator which is used on air conditioner equipped cars, see paragraph 10-22 (c) in the 1958 manual.

The voltage regulator has a bi-metal armature hinge for thermostatic temperature control. This automatically permits regulation to a higher voltage when the unit is cold, and a lower voltage when hot, because a high voltage is required to charge a cold battery.

As previously stated, the current and voltage regulators do not operate at the same time. When current requirements are large, the 1959 Buick generator voltage is too low to cause voltage regulator to operate, therefore the current regulator operates to limit maximum output of 1959 Buick generator. When current requirements are small, the generator v9ltage is increased to the value which causes voltage regulator to operate. The 1959 Buick generator output is then reduced below the value required to operate the current regulator, consequently all control is then dependent on the operati6n of voltage regulator.

Resistances

The current or voltage regulator circuit each uses its own resistance which is inserted in the field circuit when either regulator operates.

A third resistance is connected between the cutout relay base plate and the voltage regulator winding which reduces the strength of the voltage winding.

The sudden reduction in field current occurring when either the current or voltage regulator contact points open, is accomplished by a surge of induced voltage in the field coils as the strength of the magnetic fields change. These surges are partially dissipated by the two resistances, thus preventing excessive arcing at the contact points.

10-23 INSPECTING, TESTING, TROUBLESHOOTING 1959 BUICK GENERATOR – ON CAR

As a general rule, the 1959 Buick generator should be inspected and tested every 5000 miles to determine its condition; however, the type of service in which some generators are used may make more frequent inspection advisable. High speed operation, excessive dust or dirt, high temperatures and operation of generator at or near full output most of the time are all factors which increase bearing, commutator and brush wear.

Inspection of 1959 Buick Generator

The following inspection will disclose whether the 1959 Buick generator is in proper condition for service or in need of removal for repairs.

- Using a good light and a mirror, inspect the commutator through the openings in the commutator end frame. Low or unsteady output may result if the commutator is coated with grease or dirt, or is rough, out of round, or has high mica between the bars. If commutator bars are burned an open circuit is indicated.

- Inspect commutator end of 1959 Buick generator for thrown solder, indicating that generator has been overheated due to excessive output.

Excessive output usually results when the generator field is grounded, either internally or at the regulator. If this is indicated, disconnect the wire at “F” terminal of generator or regulator and run engine at medium speed. If 1959 Buick generator output drops off the regulator is at fault but if output remains high the field is grounded internally in generator. If the field is found to be grounded, the regulator will probably have to be replaced.

- Check condition of brushes; make sure they are not binding in holders and that they are resting on the commutator with sufficient tension to give good, firm contact. Brush leads and screws must be tight. If the brushes are worn down to one-half their original length, compared with new brushes, the generator must be removed for installation of new brushes.

- If the commutator or brushes are in bad condition, other than being dirty, the 1959 Buick generator should be removed for repairs (par. 10-25). If these parts are only dirty, however, they may be cleaned without removal of 1959 Buick generator.

Clean off any grease with a cloth soaked with carbon tetrachloride or other non-inflammable solvent. A brush seating compound in paste form is particularly useful when seating brushes on extruded frame generators. To seat the brushes, place a small amount .of this compound across the width of the commutator and operate the generator a short time. The abrasive particles of this compound are carried under the brushes and quickly wear the contacting faces to the contour of the commutator. All dust should be blown from the 1959 Buick generator after the brushes are seated.

- Check fan belt for condition and proper tension (fig. 2-37), make certain that all 1959 Buick generator mounting bracket and brace bolts are tight. A loose fan belt will permit belt slippage, resulting in rapid belt wear and low or erratic generator output. An excessively tight belt will cause rapid belt wear and rapid wear of generator and water pump bearings. NOTE : If belt requires adjustment, first loosen belt so that 1959 Buick generator pulley is free, then check pulley for tightness and check generator bearings for freeness of rotation and excessive side play. Rough or excessively worn bearings should be re placed.

- Inspect and manually check all wiring connections at generator, regulator, charge indicator, junction block and battery to make certain that connections are clean and tight. Clean any loose connections before tightening, to insure good contact. Inspect wiring for broken insulation, broken strands, and loose terminals. Make any corrections necessary to eliminate excessive resistance.

Testing 1959 Buick Generator Output

After inspection is completed, it is advisable to test the 1959 Buick generator output. Before making the following tests, however, make certain that the battery specific gravity is at least 1.215.

CAUTION: With the double contact (air condition) voltage regulator, never g round the generator field while the field lead is connected to the regulator, as this would result in the burning of the voltage regulator upper contacts.

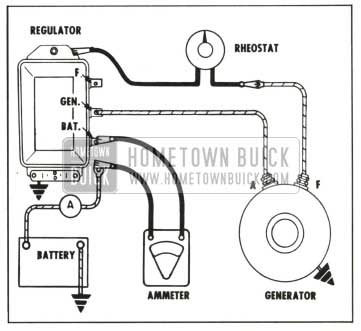

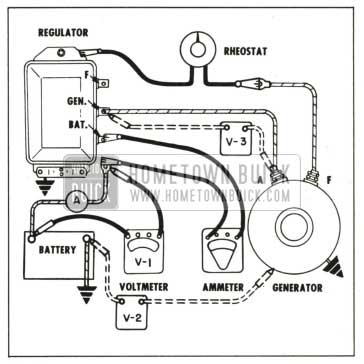

- Disconnect field lead from 1959 Buick generator regulator “F” terminal and connect a field rheostat (25 ohm-25 watt) between this lead and ground.

See Figure 10-12. Turn variable resistance to the “open” position.

1959 Buick Testing Generator Output

- Disconnect battery lead from fuse at regulator “Bat” terminal. Connect test ammeter red lead to “Bat” terminal and ammeter black lead to battery lead. See Figure 10-12.

- Connect a reliable tachometer between distributor terminal of coil and ground.

- Start engine and with engine at slow idle, turn rheostat to the “0 OHMS” position. Turn on all accessory load (bright lights, hi blower, radio, etc.).

- Slowly increase engine speed until ammeter registers 35 amperes with a standard generator or 45 amperes with an air condition generator. At this generator output, engine speed should not be over 1100 RPM. Return engine speed to idle immediately after taking reading. CAUTION: Never exceed 1100 RPM of engine with “F” lead grounded or the resulting high voltage may damage electrical units.

- If full ampere output cannot be obtained at approximately 1100 RPM of engine, check fan belt for proper tension. If fan belt is not slipping, generator does not have proper output. Remove generator for testing and make the necessary corrections before attempting any adjustment of 1959 Buick generator regulator.

- Turn field rheostat to the “OPEN” position. Turn off all accessory load. Leave ammeter and field rheostat in place for the charging circuit test.

Testing Charging Circuit Wiring

Excessive voltage drop in the charging circuit (resulting from poor connections or other high resistance) tends to keep the battery in an undercharged condition. To check voltage drop, proceed as follows:

- Make sure that all accessories are turned off and that ammeter and field rheostat are in place. See Figure 10-12.

- Make sure that rheostat variable resistance is in the “OPEN” position. Set carburetor on high step of fast idle cam (approximately 1500 RPM). Then slowly turn variable resistance knob until ammeter reads 20 amperes.

- Measure voltage drop at V-1, V-2, and V-3. Return rheostat knob to “OPEN” position immediately after taking readings. See Figure 10-12. Readings V-1 and V-3 should not exceed .3 volt each. Reading V-2 should not exceed .1 volt. See Figure 10-13.

1959 Buick Testing Charging Circuit Voltage Drop

10-24 BENCH TEST OF 1959 BUICK GENERATOR

The following inspection and test of 1959 Buick generator, after removal from car, may be used to determine the cause of unsatisfactory output before generator is disassembled.

- Inspect condition of brushes and commutator as described in paragraph 10-23. If brushes and commutator are in satisfactory condition and the cause of trouble is not apparent proceed to the following steps.

- Place piece of cardboard between commutator and grounded brush. Using test lamp and points, check for grounds with test points on “A” terminal and generator frame. If lamp lights, the 1959 Buick generator is internally grounded. Locate the ground by insulating the other brush also, and checking the brush holders, armature, commutator and field separately.

- If 1959 Buick generator is not grounded, check the field for open circuits by placing one test lamp point on the “F” terminal and the other point on the insulated brush holder to which the other end of field coil is connected. If lamp does not light the field has open circuit. If the open circuit is due to a broken lead or bad connections, it can be repaired but if the open circuit is inside one of the field coils the coil must be replaced.

- If the field is not open, check for a short circuit by connecting a 12-volt battery and an ammeter in series with the field coils. Proceed with care since a shorted field may draw excessive current which might damage the ammeter. See paragraph 10-2 (a) for the field current draw specifications for the type generator being tested. A high reading indicates a short circuit.

- If the cause of trouble has not been located, disassemble 1959 Buick generator for test of armature (par. 10-25).

- If a shorted field is found be sure to check for burned contact points in the generator regulator (par. 10-26) because a shorted field may permit an excessive field current which could burn the contact points.

- When testing 1959 Buick generator on a generator and regulator tester, a standard generator must be able to put out 35 amperes (cold) at 14 volts when generator speed is 2630 RPM. An air condition generator must be able to put out 45 amperes under the same conditions.

10-25 1959 BUICK GENERATOR REPAIRS ON BENCH

Disassembly, Cleaning and Inspection

When it is necessary to disassemble 1959 Buick generator for any reason, make a complete clean up and test to make sure all parts are in satisfactory condition. See figure 10-13 for identification of 1959 Buick generator parts.

- Unscrew both through bolts and remove the commutator end frame from the field frame.

- Disconnect brush leads and remove brushes from holders, then remove armature, drive end frame and pulley assembly from the field frame.

- Hold armature in vise equipped with soft jaws, and avoid excessive tightening of vise. Remove pulley nut, lock washer, pulley, fan, key, collar, and drive end frame from armature shaft. Remove spacer washer.

- Remove bearing retainer plate, gasket, bearing, plate and felt washer from drive end frame.

- Thoroughly clean and inspect the ball bearings, and if satisfactory for use, pack them with high melting point ball bearing grease. Replace worn or rough bearing.

- Clean all other parts by wiping with clean cloths. The armature and field coils must not be cleaned in any degreasing compound since this might damage insulation so that a short or ground would subsequently develop.

- Carefully inspect all parts for wear or damage and make necessary repairs, or replace unserviceable parts. Any soldering must be done with rosin flux; never use acid flux on electrical connections. If brush springs are distorted or show evidence of damage, replace them.

Testing and Repairing Armature

Before making any repairs to the armature, test it for open, shorted or grounded circuits.

Open circuits in armature are usually obvious since the open circuited commutator bars are usually burned as a result of arcing as they pass under the brushes. If 1959 Buick generator has overheated and thrown solder, the open circuit will be at connections to commutator riser bars. Repair can be affected by resoldering leads to riser bars, using rosin flux.

Test for grounds, using test lamp and points, by placing one test point on armature core and the other test point on commutator. If lamp lights, the armature is grounded. If grounds are at points where coils come out of slots in core, repairs can be made by placing insulating strips between core and coil which is grounded.

Check armature for short circuits by placing it on a growler and slowly turning armature while holding a thin strip of steel (hacksaw blade) above armature core. The steel strip will vibrate when above the area of armature core in which any short circuited coils are located. Copper or brush dust in slots between commutator bars may cause shorts between bars which can be eliminated by cleaning out the slots. Shorts at cross-over of coils at the drive end can often be corrected by bending the wires slightly and reinsulating the exposed bare wire.

If armature is otherwise satisfactory but commutator is worn, burned, out of round, or has high mica between bars, the commutator should be turned true in a lathe. After turning, undercut mica %2″, then carefully clean all dirt and copper dust out of slots. Lightly polish the commutator with 2/0 sandpaper to remove all slight burrs left by undercutting operation.

Replacement of Brush Holders

When it is necessary to replace a brush holder, drill out the attaching rivet with a No. 2 drill to remove old holder from the field frame. Attach the new brush holder with the screw, lock washer, and nut provided in the brush holder service package.

When installing the insulated brush holder place insulating bushing on attaching screw with flat side against screw head. Locate screw and bushing in hole of brush holder, force flat sided hole of insulating strip over screw threads, install parts in field frame and install lock washer and nut on screw finger tight. Thread the terminal stud through slot in brush holder and round hole in insulating strip, then install insulating bushing, flat washer, lock washer, and nut. Tighten attaching screw and stud nuts securely. Attach field coil and brush leads to inner end of terminal stud.

Assembly and Installation of 1959 Buick Generator

Assemble 1959 Buick generator by reversing the disassembly procedure, paying attention to the following points:

- If field coils were removed from the field frame be sure that insulation is placed between the coils and the pole shoes. Use care in tightening pole shoe screws to avoid distortion of parts, and make sure that screws are securely tightened.

- After the commutator end frame is installed to support the armature check the tension of both brush springs, using Brush Tension Checking Scale J 5184.

When using the scale, apply a steady pull at 90 degrees to brush arm and note the scale reading at instant that brush arm is lifted off the brush. The reading should be between 26 and 32 ounces. If tension is not within these limits replace springs.

- New brushes must be seated to make good contact with armature, using a brush seating stone. This is a soft abrasive material which, when held against a revolving commutator, disintegrates so that particles are carried under the brushes and wear their contacting faces to the contour of the commutator in a few seconds. This operation may be performed on the bench if means are available for turning the armature, or it may be performed after 1959 Buick generator is installed on engine. Blow all dust out of generator after the brushes are seated.

- Connect the white armature wire to the “A” terminal of 1959 Buick generator. This is the right hand terminal, farthest from engine. Connect the pink field wire to the left hand terminal.

CAUTION: Connect radio condenser to armature output “A” terminal.

- Before the engine is started, momentarily bridge between the “BAT” and “GEN” terminals of the generator regulator with a jumper wire or screwdriver. This allows a momentary surge of current from battery to 1959 Buick generator, which correctly polarizes the generator with respect to the battery. Adjust fan belt as shown in figure 2-37.

10-26 TEST AND ADJUSTMENT OF 1959 BUICK GENERATOR REGULATOR ON CAR

1959 Buick Generator Disassembled-Air Conditioned Car

Preliminary Instructions

The 1959 Buick generator regulator should be tested when difficulty is experienced in keeping the battery charged, or when battery uses an excessive amount of water, which is usually caused by a high charging rate. Before testing the 1959 Buick generator regulator make certain that the generator and circuit wiring are in good condition by performing the inspection and test given in paragraph 10-23.

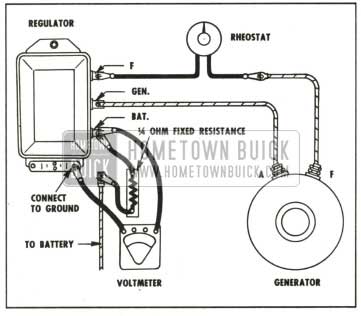

The “Fixed Resistance” method of testing the operation and calibration of the 1959 Buick generator regulator is recommended in preference to the “Variable Resistance” method which employs a variable resistance connected in series between the generator regulator and the car battery. The “Fixed Resistance” method uses a calibrated fixed resistance (1/4, ohm, approximately 25 watts) in series between generator regulator and car battery. All tests can be made without removing regulator cover, therefore proper regulator temperature can be maintained during tests.

The procedure given below in subparagraph d provides a “Fixed Resistance” method of testing the generator regulator. CAUTION: Never under any circumstances attempt to adjust 1959 Buick generator regulator without first hooking up an approved test instrument. Serious damage to generator, battery, or other electrical units might result if regulator were improperly adjusted.

After any test or replacement of regulator, the car generator must be polarized after all wires are connected but before engine is started. Failure to polarize generator may result in severe damage to the equipment since reversed polarity causes vibration, arcing and burning of the relay contact points. The 1959 Buick generator may be readily polarized by momentarily bridging between the “BAT” and “GEN” terminals of regulator to cause a surge of current through the generator.

Always make certain that rubber gasket is in proper position to seal regulator cover when installed. The gasket prevents entrance of dust, moisture, and oil vapors which might damage the regulator.

Calibration of Test Voltmeter

The calibration of the test voltmeter should be frequently checked and should always be checked immediately following malhandling, sluggish movement of pointer, or when the meter has been dropped.

If the instrument being used does not have built-in provision for checking the calibration of the voltmeter and no commercial testing laboratory is available, the voltmeter may be calibrated against a specially prepared storage battery as follows:

- Select a satisfactory new 12-volt automotive storage battery and charge slowly (1 amp. per positive plate) until fully charged. Specific gravity of electrolyte should read between 1.260 and 1.280 in all cells. Allow battery to stand overnight at approximately 80°F. for stabilization of voltage. Battery terminal voltage will then be 12.8 volts. CAUTION: Do not use battery for calibration immediately after charging because battery voltage will be abnormally high for several hours.

- Check the test voltmeter against prepared battery and note reading. If meter does not read 12.8 volts, calculate the difference. Assume that error will be the same between 14 and 15 volts and allow this difference when using voltmeter to test and adjust 1959 Buick generator regulator. If voltmeter is found faulty it should be repaired at first opportunity.

The prepared calibrating battery also may be used to check an open circuit type battery testing meter by measuring the voltage of one cell, which will be 2.13 volts.

Testing Regulator for Oxidized Points

Abnormal fluctuation of the charge indicator, or of the voltmeter or ammeter pointer while testing the voltage or current regulator indicates an oxidized condition of regulator contact points. This condition may cause a high resistance in the 1959 Buick generator field circuit and reduced generator output. Test for oxidized contact points as follows:

- With engine stopped, disconnect battery lead from fuse at regulator terminal marked “BAT.” Connect ammeter red lead to fuse at “BAT” terminal and ammeter black lead to battery lead.

- Turn on headlights. Start engine and adjust speed until test ammeter reads exactly 5 amperes.

- Disconnect field lead from regulator “F” terminal and ground it on regulator base. See figure 10-15. If ammeter reading increases more than 2 amperes, oxidized contact points are indicated. Regulator should be removed and contact points cleaned before proceeding to any other regulator tests. See paragraph 10-27 for cleaning procedure.

1959 Buick Testing Regulator for Oxidized Points

CAUTION: Never use a jumper to ground the 1959 Buick generator or regulator field terminal when these units are connected and operating together, as this would burn the contacts of the voltage regulator.

Test and Adjustment of 1959 Buick Generator Regulator

Before testing or adjusting the generator regulator, it is advisable to first test the generator output and the charging circuit wiring as described in paragraph 10-8. If generator output or charging circuit voltage drop are not within specifications, repairs should be made before testing the 1959 Buick generator regulator.

The following is the procedure in general for making tests and adjustments of the cutout relay, voltage regulator and current regulator in the order named. For specific instructions, refer to the pamphlet which was received with your test instrument. NOTE : Regulator cover must be in place during all tests.

- Before using tester, make sure all needles on instrument are properly calibrated according to manufacturer’s instructions.

- Connect tachometer from distributor terminal of coil to ground.

- Disconnect battery lead from fuse at regulator terminal marked “Bat.” Connect ammeter red lead to fuse at “Bat” terminal and ammeter black lead to battery lead. CAUTION: Never allow one ammeter clip to touch ground while other clip is connected to a source of current or ammeter will be damaged.

- Turn voltmeter selector switch to position for 12 volt system. Then connect voltmeter red lead to “Gen” terminal of regulator and voltmeter black lead to ground on base plate of regulator. See Figure 10-16.

1959 Buick Testing Cutout Relay

CAUTION: Never close relay contacts by hand with battery connected to regulator because this will cause a damaging high current arc across contacts.

- Voltage Regulator Test. Turn rheostat variable resistance to “OPEN” position and change one rheostat lead from ground to “F” terminal of regulator. Connect a 1/4 ohm resistor (approximately 25 watts) into charging circuit at “Bat” terminal of regulator. See Figure 10-17.

1959 Buick Testing Voltage Regulator

CAUTION: Since the voltage and current regulators are both compensated for temperature, the following tests must be made with the regulator at operating temperature with the cover in place to insure accurate results.

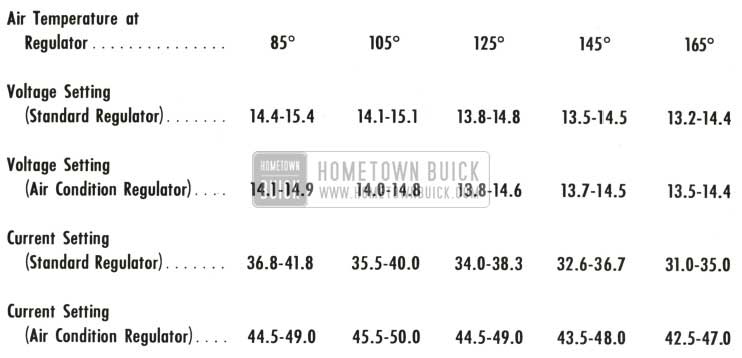

- Increase engine speed to 2000 RPM. Cycle the regulator by turning rheostat knob to “OPEN” then back to “0 OHMS.” Now read voltmeter which indicates the maximum operating voltage. See figure 10-18 for the correct maximum voltage setting of the type regulator being tested for the existing temperature.

1959 Buick Chart for Setting Voltage and Current Regulators

NOTE: The voltage “difference” between the operation of upper and lower contacts is increased by SLIGHTLY increasing the air gap between the armature and the center of the core and decreased by SLIGHTLY decreasing the air gap. See Step 20 below for procedure. If this adjustment is made, it will also affect the maximum operating voltage (upper contact operation), so the maximum voltage must be rechecked.

- Current Regulator Test. (Current regulator test must be made as soon as possible after making voltage regulator test.) Set engine speed at 1500 RPM. Turn rheostat variable resistance to “0 OHMS” position. Remove ohm resistor. CAUTION: Do not allow disconnected lead to touch ground on car.

- Turn on all accessory load (lights, radio, blower, etc.) and connect an additional load from the charging circuit to ground and connect ammeter as described in your test instrument pamphlet. Adjust load to lower voltage to 13.0 volts. See Figure 10-19.

1959 Buick Testing Current Regulator

CAUTION: Never substitute an Air Conditioner regulator for a standard regulator as this might cause generator to burn out.

- If there is abnormal fluctuation of voltmeter or ammeter pointer while testing voltage or current regulator, test for oxidized contact points.

- If contact points are in satisfactory condition but either the voltage or current regulator did not operate within specified limits adjust armature spring tension as required. Turn adjusting screw clockwise to increase operating voltage or charging rate. The final setting must always be made by turning screw clockwise to increase voltage or charging rate never by turning counterclockwise.

If adjusting screw is turned clockwise beyond normal range required for adjustment, the spring support may be bent so that it fails to return when pressure is relieved. If this happens, turn the screw counterclockwise until sufficient clearance exists between screw head and spring support, then bend support upward carefully until contact is made with screw head. Make final adjustment as described above.

- On air condition (double contact) regulator s only , if voltage “difference” between operation of upper and lower voltage regulator contacts was not within limits (.1 to .3 volts), adjust air gap between armature and center of core as required. To increase voltage “difference,” increase air gap by loosening contact support bracket screw 1/8 to 1/4 turn. Then place a screwdriver through slot in bracket into molded insultor and raise on handle slightly.

Retighten contact support bracket screw securely. To decrease voltage “difference,” air gap must be decreased.

- After any adjustment of either regulator unit install cover and gasket, bring regulator up to operating temperature and recheck setting.

- Upon completion of all tests and adjustments, first return engine speed to idle, then disconnect regulator test equipment and reconnect battery wire to “BAT” terminal of regulator.

- Set engine idle speed at 485 RPM on standard cars or 550 RPM on air conditioned cars, then disconnect tachometer.

10-27 1959 BUICK GENERATOR REGULATOR REPAIRS-ON BENCH

The contact points of a regulator will become oxidized and pitted after extended service and require cleaning. Contact points also may be burned because of faulty connections in the charging circuit, shorts or grounds in the generator field circuit, installation of a radio bypass condenser on the “F” terminal of generator or regulator, or accidentally grounding the 1959 Buick generator or regulator field terminal while these units are connected and operating together.

The majority of regulator troubles arise from dirty and oxidized contact points, which cause a reduced generator output. If contact points are not badly burned, cleaning followed by testing and adjusting will correct faulty regulator operation in most cases. However, if contact points are badly burned, it is generally better to replace the 1959 Buick generator regulator.

The contact points are of a soft material and should be cleaned with crocus cloth or a similar fine abrasive material. After cleaning, thoroughly wash the contact points with trichlorethylene or alcohol to remove any foreign particles.

CAUTION: Never use emery cloth or sandpaper on the contact points because particles of emery or sand may become imbedded and cause the points to arc and burn.

After thoroughly cleaning and washing the contacts, make the 1959 Buick generator regulator tests and adjust if necessary. If the regulator still does not operate in a satisfactory manner, replace the regulator.

Leave A Comment

You must be logged in to post a comment.