SECTION 5-A 1958 BUICK VARIABLE PITCH DYNAFLOW TRANSMISSION SPECIFICATIONS, DESCRIPTION AND OPERATION

5-1 1958 BUICK VARIABLE PITCH DYNAFLOW GENERAL SPECIFICATIONS

1958 Buick Variable Pitch Dynaflow Transmission Identification Number

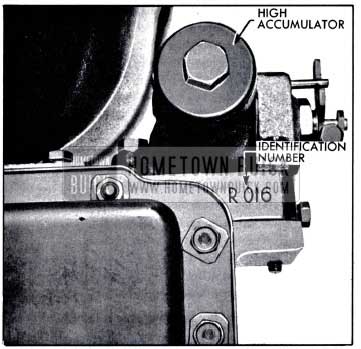

A production identification number is stamped into the lower edge of the reaction shaft flange directly to rear of the high (left) accumulator. The identification number consists of a letter followed by a number. See figure 5-1.

1958 Buick Location of Variable Pitch Dynaflow Transmission Identification Number

Since the production identification number furnishes the key to construction and interchangeability of parts in each transmission the number should be used when selecting replacement parts as listed in the Master Parts List. The number should always be furnished on Product Reports, A.F.A. forms, and correspondence with the factory concerning a particular transmission.

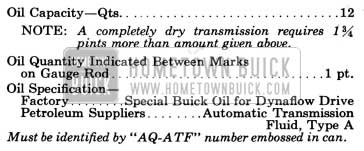

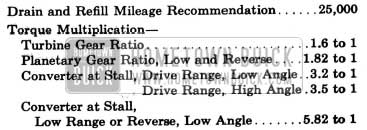

General Specification

1958 Buick Variable Pitch Dynaflow Transmission Specifications

1958 Buick Variable Pitch Dynaflow Transmission Specification

1958 Buick Variable Pitch Dynaflow Transmission General Specifications

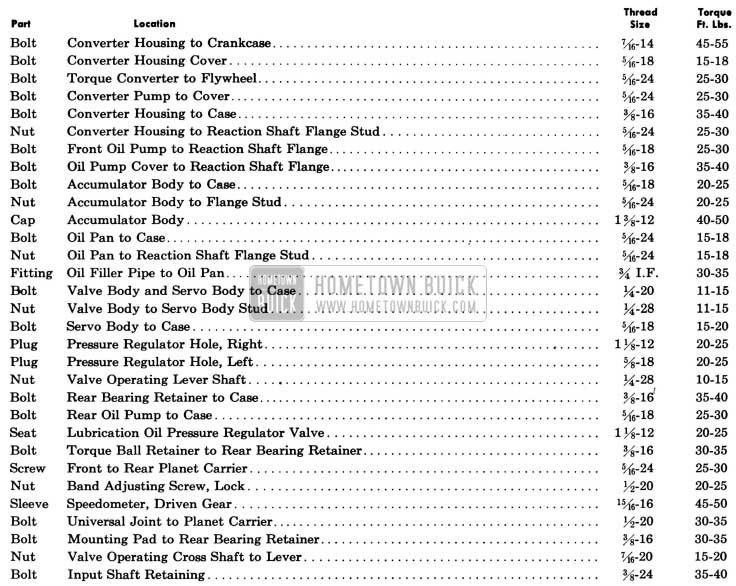

5-2 TIGHTENING, TEST AND ASSEMBLY SPECIFICATIONS

Tightening Specifications

Use a reliable torque wrench to tighten the attaching bolts or nuts of the parts listed below. These 1958 Buick Variable Pitch Dynaflow Transmission specifications are for clean and lightly lubricated threads only; dry or dirty threads produce increased friction which prevents accurate measurement of tightness.

1958 Buick Variable Pitch Dynaflow Transmission Tightening Specifications

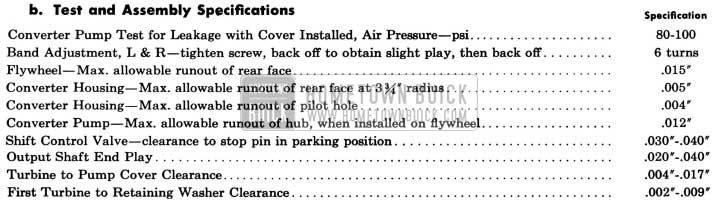

Test and Assembly Specifications

1958 Buick Variable Pitch Dynaflow Transmission – Test and Assembly Specifications

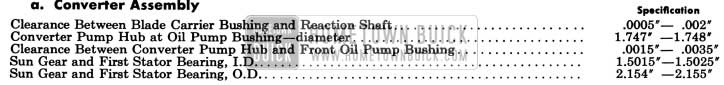

5-3 1958 BUICK VARIABLE PITCH DYNAFLOW PRODUCTION LIMITS AND FITS OF NEW PARTS

NOTE: These specifications apply to new parts only and must be used with discretion when checking worn-in parts. The limits established for new parts allow for reasonable wear through normal use; therefore, parts which have been in service and have been operating satisfactorily should not be replaced simply because they slightly exceed the limits specified for new parts.

1958 Buick Converter Assembly

1958 Buick Variable Pitch Dynaflow Converter Assembly Specifications

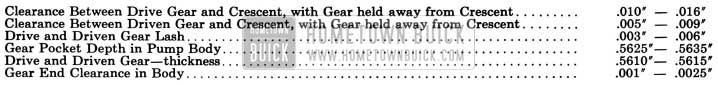

1958 Buick Front Oil Pump

1958 Buick Variable Pitch Dynaflow Front Oil Pump Specifications

1958 Buick Reaction Shaft Flange

1958 Buick Variable Pitch Dynaflow Reaction Shaft Flange Specifications

1958 Buick Accumulators

1958 Buick Variable Pitch Dynaflow Accumulators Specifications

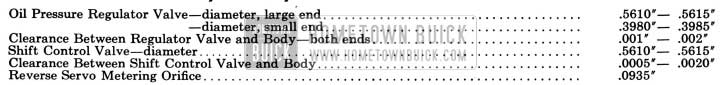

1958 Buick Valve and Servo Body Assembly

1958 Buick Variable Pitch Dynaflow Valve and Servo Body Assembly Specifications

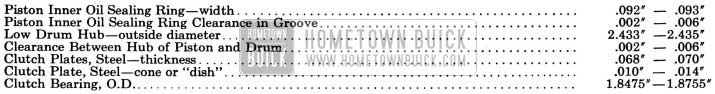

1958 Buick Variable Pitch Dynaflow TransmissionClutch

1958 Buick Variable Pitch Dynaflow Clutch Specifications

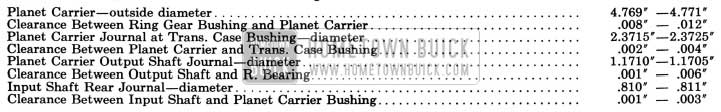

1958 Buick Variable Pitch Dynaflow TransmissionPlanetary Gear Set and Reverse Ring Gear

1958 Buick Variable Pitch Dynaflow Planetary Gear Set and Reverse Ring Gear Specifications

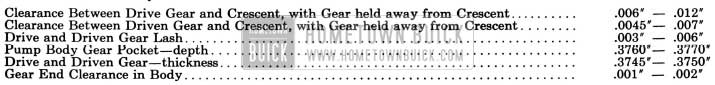

1958 Buick Variable Pitch Dynaflow TransmissionRear Oil Pump

1958 Buick Variable Pitch Dynaflow Rear Oil Pump Specifications

Rear Bearing

1958 Buick Variable Pitch Dynaflow Rear Bearing Specifications

5-4 1958 BUICK VARIABLE PITCH DYNAFLOW MANUAL CONTROL MECHANISM AND OPERATING INSTRUCTIONS

Manual Control Mechanism

Dynaflow Drive provides five different control or operating ranges which may be manually selected by the driver through movement of the shift control lever at top of steering column. A pointer on the control lever housing and a stationary dial mounted on steering column aid in locating the lever for each range. Letters on the dial, reading from left to right identify each range as follows:

P=Parking

L=Low

N=Neutral

R=Reverse

D=Direct Drive

It is necessary to raise the control lever against light spring pressure when shifting into Parking (P), Neutral (N) or Reverse (R).

The control lever actuates a control shaft in steering column which is connected by levers and rods to a shift control valve in the 1958 Buick Variable Pitch Dynaflow Transmission. A detent lever and notched plate in the rear bearing retainer holds the shift control mechanism in the selected position.

The control shaft also operates a neutral safety switch mounted on the column jacket. The switch, which is connected into the cranking motor control circuit, is closed so that the engine can be cranked only when the control lever is in either the Neutral (N) or Parking (P) position, thereby preventing accidental movement of the car when the engine is started.

Parking (P) Range

Parking range is to be used in conjunction with the “step-on” parking brake to insure positive locking of car on steep grades. The shift control lever must be raised when shifting into or out of Parking position.

Parking range must never be entered when the car is in motion as serious damage to transmission will result.

For safety, Parking range should always be used when it is desirable to run and accelerate the engine without possibility of car movement, as when working on car in the shop.

When in Parking range, a parking lock ratchet wheel on transmission output shaft is engaged by a locking pawl mounted in the transmission rear bearing retainer, thereby providing a positive mechanical lock for the rear wheels. The locking pawl is actuated by the 1958 Buick Variable Pitch Dynaflow Transmission shift control linkage through an apply spring which holds the pawl against the ratchet wheel until engagement of these parts is accomplished. If the pawl does not engage a notch in ratchet wheel when first applied it will snap into place as the wheel turns when car moves slightly.

The engine may be started while the car is locked in Parking position.

Neutral (N) Range

Neutral range as well as Parking range may be used when starting the engine. It is not necessary to shift into Neutral when the car is temporarily stopped with engine running during normal driving operation.

Neutral must always be used when towing the car with rear wheels on the road.

Neutral range may be used when it is desirable to run and accelerate the engine without car movement, but Parking range is recommended for this condition because of greater safety.

Direct Drive (D) Range

Direct Drive range is to be used for all forward driving conditions except as specified for low range.

During part throttle operation in Drive range the 1958 Buick variable pitch stator is in “cruising” position. When powerful acceleration is required, as for passing other vehicles on grades, the stator may be changed to the “performance” position by pushing the accelerator pedal to floor mat.

Low (L) Range

Low range is used only when the engine is under an exceptionally heavy load, such as in deep snow or sand or on long steep grades. Low range can be used to obtain additional engine braking when descending steep grades.

The shift between Low and Direct Drive ranges may be made while the car is in forward motion, but the D to L shift must never be made at speeds above 40 MPH. The 1958 Buick variable pitch stator operation is limited to “cruising” position in Low range.

Reverse (R) Range

Reverse range is used to move the car rearward. The shift control lever must be raised to shift into Reverse. The 1958 Buick Variable Pitch Stator operation is limited to “cruising” position in Reverse range.

Rocking Car Between Low and Reverse

When the car is stuck in deep snow or mud it can be driven out by “rocking the car back and forth by alternately using Low and Reverse until sufficient momentum is obtained to move car out in desired direction.

After accelerating engine slightly to provide sufficient power, hold shift control lever up and move it back and forth between Low and Reverse. Control the engine speed and time the movement of control lever so that the rear wheels push firmly against the snow or mud in each direction but avoid spinning the rear wheels.

Pushing or Towing Car to Start Engine

If it becomes necessary to push a Dynaflow Drive car to start the engine, place shift control lever in Neutral (N) until car speed reaches approximately 15 MPH, then shift into Low (L). Continue to increase car speed until engine cranks (approximately 25 MPH). After engine starts, return control lever to Neutral (N) for engine warm up. It is safer to push car than tow it.

Towing Disabled Dynaflow Drive Car

A disabled Dynaflow Drive car must not be towed on rear wheels with 1958 Buick Variable Pitch Dynaflow Transmission in any of the driving ranges because unnecessary damage to transmission may result. It may be safely towed in Neutral (N) only, and towing speed should not exceed 35 m.p.h.

5-5 PRINCIPLE SECTIONS OF THE 1958 BUICK VARIABLE PITCH DYNAFLOW TRANSMISSION

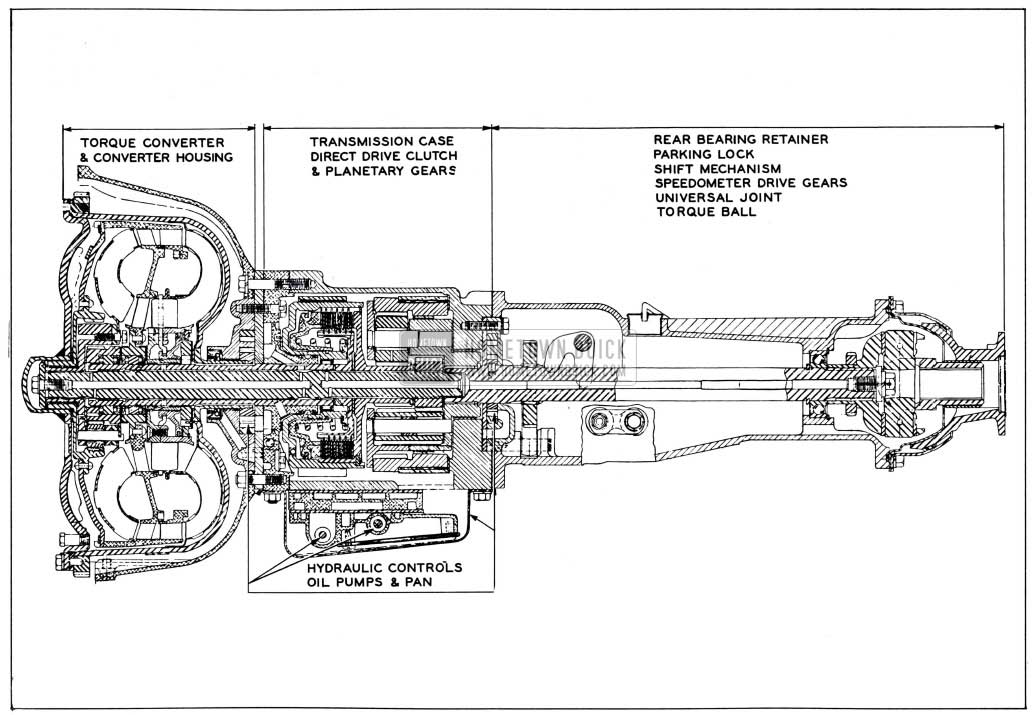

To simplify description of construction and operation of the 1958 Buick Variable Pitch Dynaflow Transmission assembly, it will be divided into the following four sections, as shown in figure 5-2.

1958 Buick Side Sectional View of Variable Pitch Dynaflow Transmission

1958 Buick Torque Converter and Converter Housing

The 1958 Buick Variable Pitch Dynaflow Transmission assembly is solidly attached to the engine crankcase by the housing which incloses the 1958 Buick torque converter.

The torque converter is connected to the engine flywheel and serves as a hydraulic coupling through which engine torque is transmitted to drive the car. In addition, it automatically provides torque multiplication as required under all ordinary driving conditions.

Construction and operation of the torque converter are described in paragraph 5-6.

1958 Buick Variable Pitch Dynaflow Transmission Case, Direct Drive Clutch, and Planetary Gears

The transmission case is bolted to the converter housing and to the rear bearing retainer. The case incloses the direct drive clutch and a planetary gear set which provides Reverse and a forward Low Range gear ratio.

The direct drive clutch locks the planetary gears so that no gear action can occur when direct drive is required. When the clutch is disengaged and the planetary gears are released so that they cannot transmit torque, the engine is disconnected from propeller shaft so that it cannot move the car. This condition exists in the Parking and Neutral ranges.

The Low Range gear ratio is provided for exceptional load conditions where the torque multiplication provided by the torque converter is inadequate. Low range also may be used for engine braking on very long or steep grades.

Construction and operation of the direct drive clutch and planetary gears are described in paragraph 5-7.

1958 Buick Variable Pitch Dynaflow TransmissionHydraulic Control System

The hydraulic control system includes all devices for controlling operation of the direct drive clutch, the planetary gears and the 1958 Buick variable pitch stator through oil pressure. The hydraulic system also provides for filling the torque converter and circulation of oil for lubrication and cooling.

Oil pressure is provided by two pumps, one located forward of the 1958 Buick Variable Pitch Dynaflow Transmission case and the other located at the rear end of the case. With two exceptions, the units which regulate oil pressure, control operation of clutch and planetary gears, and provide selective control of all operating ranges are contained in a valve and servo body assembly mounted on the bottom of the transmission case and inclosed by the oil pan. The two exceptions are a high accumulator and a low accumulator which are externally mounted on a flange between the converter housing and transmission case. These units are not shown in figure 5-2.

Construction and operation of all hydraulic control units are described in paragraph 5-8.

Rear Bearing Retainer and Torque Ball

The rear bearing retainer is bolted to the rear end of 1958 Buick Variable Pitch Dynaflow Transmission case and the torque ball is assembled on the rear end of the retainer. The rear end of the transmission is supported upon a rubber mounting placed between the bottom of bearing retainer and a support attached to the frame.

The rear bearing retainer houses the parking lock mechanism and the shift control mechanism mentioned in paragraph 5-4. It also houses the speedometer drive gears and the universal joint.

5-6 1958 BUICK VARIABLE PITCH DYNAFLOW TORQUE CONVERTER

The 1958 Buick Dynaflow torque converter is connected to the engine flywheel and serves as a hydraulic coupling through which engine torque (turning force) is transmitted to drive the car. The torque converter steps up or multiplies the engine output torque whenever car operating conditions demand greater torque than the engine can supply. In this respect it serves the same purpose as the selective reduction gears used in other types of automotive transmissions.

Torque multiplication is always required when a car is started and accelerated at low speeds. Torque multiplication may be required when car is ascending steep grades, moving in deep sand, snow, etc. Torque requirements decrease as the car gains momentum and when a point is reached where engine torque is adequate, no torque multiplication is required. From this point, torque multiplication would be undesirable and uneconomical since it is always obtained at a sacrifice in speed.

The 1958 Buick Dynaflow torque converter automatically provides the proper ratio of torque multiplication to meet the varying demands imposed by starting and driving under all ordinary conditions of load and grade. The transition through the various ratios of torque multiplication is smooth and devoid of steps or change points since it is accomplished without the use of selective gears.

The principle elements of the “Variable Pitch” torque converter are described in subparagraphs a, b, c, and the operation of these elements is described in subparagraph d.

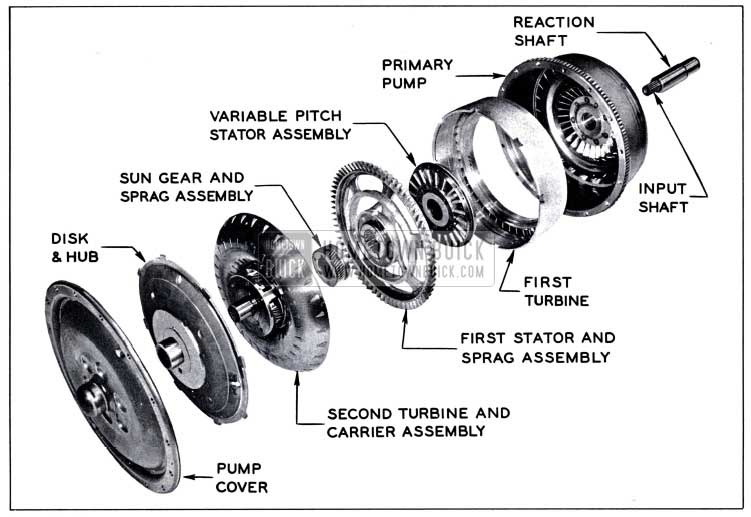

1958 Buick Variable Pitch Dynaflow Transmission Converter Pump and Cover

The converter pump is bolted to the engine flywheel so that it rotates whenever the engine is running. The pump and the cover which closes its front end form a housing for all other converter components, and this housing is kept filled with oil.

The pump is similar to the impeller of a conventional centrifugal pump but it is shaped so that it discharges fluid in a different direction. A conventional pump impeller picks up fluid at its center and discharges fluid from its rim at approximately 90 degrees to its axis of rotation. Due to the curved form of the blades and the supporting shells, the converter pump discharges oil in a direction approximately parallel to its axis of rotation and in the form of a spinning hollow cylinder. See figure 5-3.

1958 Buick Major Components of Torque Converter

The function of the converter pump assembly is to convert engine torque into an energy transmitting flow of oil with which to drive the converter turbine, into which the oil is projected from the pump.

1958 Buick Twin Turbine Dynaflow Assembly

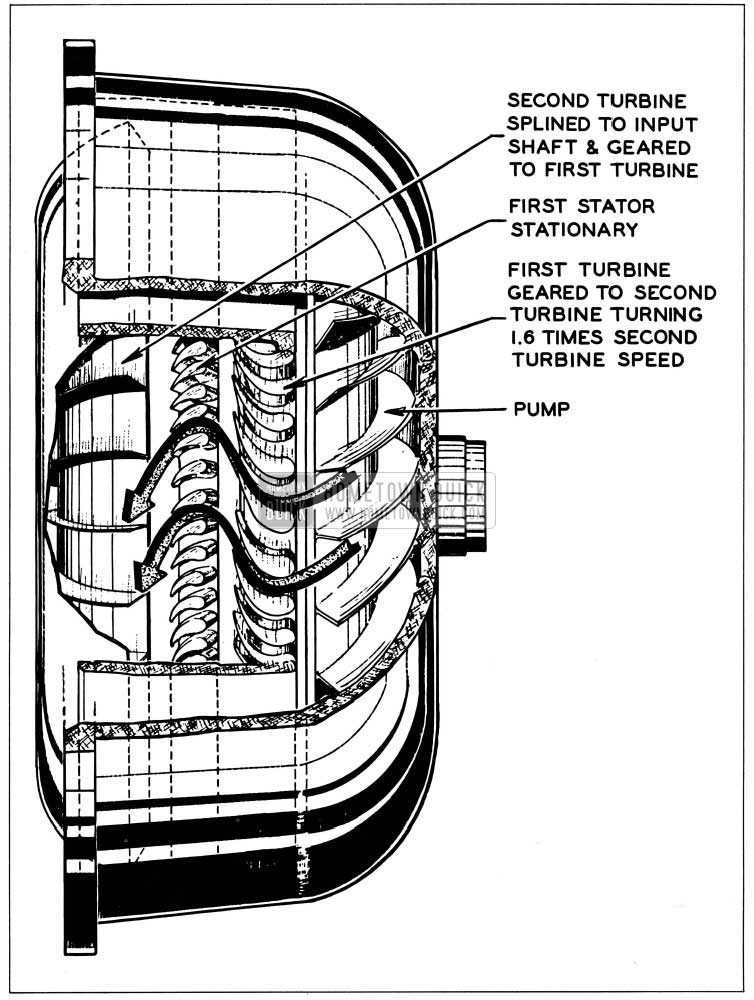

The turbine assembly is coupled to the transmission input shaft through which torque is transmitted to the direct drive clutch and the planetary gears located to rear of torque converter. The Twin Turbine assembly consists of a first turbine, a first stator, a second turbine, and a planetary gear set that connects the first turbine to the second turbine.

The first turbine has a narrow band of vanes located at the pump exit in a position to receive the spinning cylinder of oil projected from the pump. The first stator has a similar band of narrow vanes located between the first turbine and the second turbine. The second turbine is located inside the first turbine in position to receive oil directed to it from the first turbine and first stator. This turbine has a broad band of vanes shaped to direct the oil flow back into the 1958 Buick variable pitch stator in a direction opposite to converter rotation.

The second turbine is bolted to a carrier which is splined to the input shaft; therefore, the second turbine and input shaft rotate at the same speed. The first turbine is mounted on a disk and hub assembly which has a bearing on the hub of the turbine carrier. This turbine is connected to the carrier and input shaft through planetary gears. Therefore, its speed relative to the input shaft is governed by gear action.

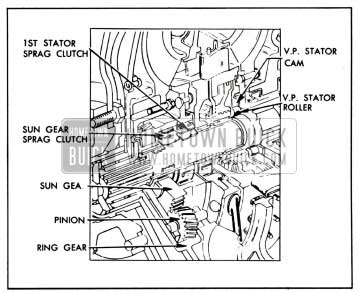

The first turbine hub contains internal ring gear teeth which mesh with four planet pinions mounted in the turbine carrier on steel pins and needle bearings. The planet pinions mesh with a sun gear supported by a bearing on the stationary reaction shaft which is anchored to a flange bolted between the converter housing and the transmission case. The sun gear contains a sprag type free wheel clutch which operates to hold the gear stationary when turbine gear reduction is required for increased torque multiplication and permits the gear to free wheel when gear reduction is not required. See Figure 5-4.

1958 Buick Converter Gears and Clutches

When engine is accelerated with car stationary, oil is emitted from the first turbine in a direction opposite pump rotation into the first stator which redirects the oil into the second turbine in the same direction as pump rotation, thus providing increased torque multiplication during acceleration.

The first stator is supported on the reaction shaft by two bronze bearings, one on each side of a sprag type free wheel clutch which holds the stator: stationary when torque multiplication is required (up to approximately 30 mph at full throttle) and allows the stator to turn with the pump when torque multiplication is not required. See Figure 5-4.

The function of the turbine assembly is to absorb energy from the oil projected into it by the pump and convert the energy into torque as determined by engine speed and load conditions.

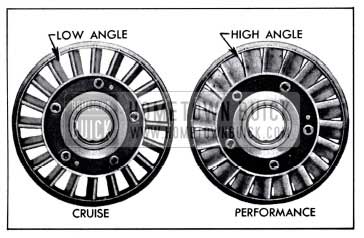

1958 Buick Variable Pitch Stator

The 1958 Buick Variable Pitch Stator is located between the second turbine exit and the converter pump entrance and is supported on the stationary reaction shaft. This stator is equipped with free wheeling clutch rollers which operate to lock it to the reaction shaft when this action is required and permit it to free wheel when not required.

The stator blades have curved surfaces which control the flow of oil between second turbine exit and pump entrance when the turbine is stationary or at low speed relative to the pump rotation. The stator blades alter the direction of flow so that oil approaches the pump at proper angle to enter without opposing pump rotation.

For normal “cruising” operation in Drive range, best performance is obtained with stator blades set at a low angle relative to the centerline of converter. For powerful acceleration increased torque may be obtained by setting stator blades at a higher angle. See Figure 5-5. These two settings are made available through the 1958 Buick variable pitch construction of the stator.

1958 Buick Stator Positions

Each of the twenty stator blades is mounted on an individual control crank which is supported at its outer end by the carrier ring and which is free to turn in its bearing in the stator carrier. The carrier contains a piston which actuates all blades through the control cranks when oil pressure is applied to one or both sides of piston as explained under operation (subpar. d, below).

As the second turbine approaches pump speed the direction of oil flow changes until it no longer opposes pump rotation. The stator then free wheels so that it will not interfere with efficient flow of oil between second turbine and pump.

The function of the stator, when stationary, is to change the direction of oil flow from the turbine to the proper angle for smooth entrance into the converter pump, so that all energy remaining in the oil may be utilized to increase pump output.

Operation of 1958 Buick Variable Pitch Dynaflow TransmissionTorque Converter

Operation of the torque converter is the same in Direct Drive, Low and Reverse, except that the 1958 Buick variable pitch stator will shift into high angle only in Direct Drive Range. The variable pitch stator is in the low angle position at part throttle and in the high angle position at full throttle. The converter transmits torque to the direct drive clutch and planetary gears through the transmission input shaft. The range of 1958 Buick Variable Pitch Dynaflow Transmission operation is determined by control of the clutch and gears as described in paragraph 5-7.

Description of torque converter operation will begin with the car stationary, 1958 Buick Variable Pitch Dynaflow Transmission in Direct Drive, and engine running at idling speed. The converter pump is turning with the engine and the turbine members are stationary.

The engine driven converter pump projects a rotating cylinder of oil into the first turbine, the vanes of which are shaped in such a manner that oil leaving them is directed backward into the first stator. The sprag type clutch on which the stator is mounted prevents stator from turning backward, causing the vanes to redirect the oil into the second turbine in the same direction as pump rotation.

At idling speed the force of oil flow against vanes is not sufficient to move either turbine and the oil flows through the first turbine, first stator and second turbine into the variable pitch stator without transmitting any appreciable amount of torque.

As the oil emerges from the second turbine near its center, the backward curvature of the exit ends of the vanes causes the oil to spin backward with reference to pump rotation as it flows into the variable pitch stator. Pressure of oil against the forward face of the stator blades causes the free wheeling clutch to lock and hold the stator stationary. The curved stator blades then change the direction of flow so the oil enters pump rotating in the same direction as the pump is turning.

When the throttle is open the engine speeds up and rapidly approaches its torque peak. With increased speed, the converter pump now projects a large volume of oil into the turbines at high rotary speed. The rotating cylindrical mass of oil may be compared to a spinning flywheel rim. A spinning flywheel has stored up energy (turning force) which may be transmitted to any mechanism which opposes its rotation. Since the vanes of both turbines oppose rotation of the spinning flywheel of oil projected from the pump the stored up energy in the oil exerts a powerful impulsion force against the vanes tending to rotate the turbines in the same direction as the pump.

At this stage the impulsion force of the oil against the vanes is not sufficient to move either turbine. The oil flows through the turbine channels and is discharged into the stator, which redirects it into the pump entrance. As the oil emerges from the second turbine into the stator, spinning at high speed in a reversed direction, it exerts a powerful reaction force against the turbine vanes, tending to rotate the turbine in the same direction as the pump.

Engine torque applied to the converter pump generates a given amount of energy in the oil projected from the pump against the turbine vanes. When the turbines are stationary, the oil passes through both turbines and the stator and returns to the pump with almost as much energy as when projected. The amount of energy in the oil thereafter projected from the pump becomes the sum of the energy in returning oil plus the energy resulting from engine torque application, or almost double the amount of energy that could be generated by engine torque alone. The greatly increased energy in the spinning flywheel of oil then projected into the turbines produces a corresponding increase in the impulsion and reaction forces upon the turbine vanes.

The described build-up of forces produces a turning force or torque upon the turbines which is much greater than the torque produced by the engine; therefore, torque multiplication is accomplished. It would seem that torque multiplication would increase indefinitely as the cycle repeats itself, but mechanical factors limit the increase of torque multiplication beyond a definite ratio in any given torque converter design.

The build-up of forces against the turbine vanes causes the first turbine to rotate in the same direction as the converter pump. The first turbine absorbs part of the energy transmitted by the oil stream and converts this energy into torque, which is imparted to the ring gear in its hub. The ring gear rotates• the planet pinions, causing them to “walk” around the stationary sun gear so that turning force is applied to the turbine carrier in which the pinions are mounted.

Oil is projected from the first turbine against the front (concave) face of the first stator blades. As the stator is prevented from turning against pump rotation by the action of the sprag clutch, the blades change the direction of oil flow into the second turbine spinning in the same direction as pump rotation, thus providing torque multiplication at low car speeds. See Figure 5-6.

1958 Buick Oil Flow from Pump to Second Turbine on Acceleration

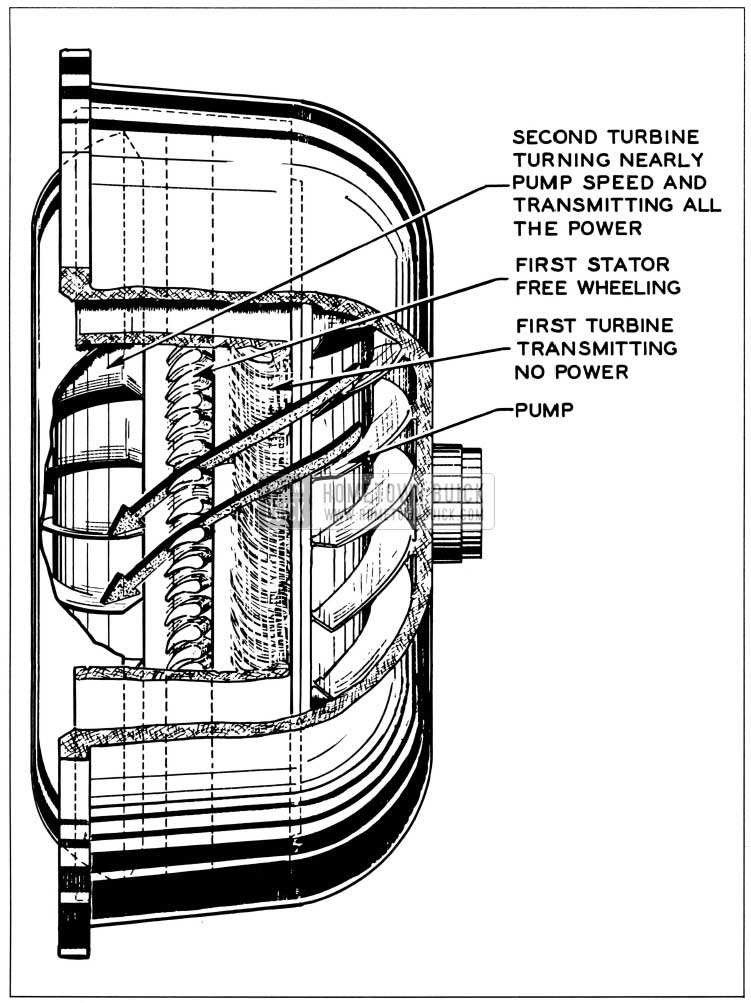

As first turbine speed more nearly approaches engine speed and the torque multiplication requirements are less, the angle at which oil emerges from the first turbine changes, striking the rear (convex) face of the first stator blades, causing the stator to turn freely or the reaction shaft thus allowing oil to flow unimpeded from the first turbine into the second turbine. See Figure 5-7.

1958 Buick Oil Flow from Pump to Second Turbine While Cruising

The second turbine absorbs energy from the oil stream after it leaves the first turbine and converts this energy into torque which is also imparted to the turbine carrier, on which this turbine is mounted. The turbine carrier transmits the torque of both turbines to the input shaft to which it is splined. See Figure 5-4.

The turbine planetary gear set gives a ratio of 1.6 to 1 when the sun gear is stationary and this reduction gearing increases the torque transmitted through the first turbine. The overall operation of the converter at low angle provides a maximum torque multiplication of approximately 3.20 to 1 at stall (car stationary and engine accelerated under load). Usually the car may be started with appreciably less than the maximum torque multiplication that is available through the converter.

As the car gains speed and momentum the demand for torque decreases so that the applied torque causes turbine speed to rapidly approach pump speed. As this occurs it is essential for torque multiplication to taper off so that car speed can be maintained at a lower, more economical engine speed. Tapering off occurs automatically because centrifugal force generated in the rapidly rotating mass of oil in the turbines creates an outward counter force which opposes the flow of oil from the pump. Reduction of oil flow and pump output energy effects a decrease in the impulsion and reaction forces upon the turbines so multiplication of engine output torque tapers off as turbine speed increases.

Reduction in speed differential between turbines and pump reduces the torque reaction on the sun gear until this reaction is entirely eliminated. The sun gear then free wheels and the first turbine ceases to be effective. As speed of the second turbine increases, the direction of oil flow into the 1958 Buick variable pitch stator correspondingly changes toward the rear face of the stator blades, thus gradually eliminating the force holding the stator stationary. Pressure of oil against rear face of blades causes the stator to free wheel at sufficient speed so that it does not interfere with flow of oil between second turbine and pump.

At this point the torque converter functions as an efficient fluid coupling, transmitting torque at a 1 to 1 ratio. Sufficient speed differential remains between pump and turbines to enable transfer of oil from pump to turbines where the oil gives up energy and returns to the pump for recirculation.

The operation described has occurred without reaching wide open throttle operation, therefore the 1958 Buick variable pitch stator blades have remained in the low angle “cruising” position. Any time the accelerator pedal is pressed to floor mat in Drive range, the 1958 Buick variable pitch stator blades will shift to the high angle “performance” position through the hydraulic control action described in paragraph 5-6. In this position the stall speed and torque multiplication of converter lire increased, providing improved performance for acceleration or pulling under load.

The various stages of the stators and turbines in the operation described do not occur at set speeds but are dependent on torque requirements imposed by car operating conditions. With light load and steady driving, torque multiplication may cease at very low car speeds, but with continued acceleration some degree of torque multiplication may be present throughout the major portion of the car speed range. When the torque converter is operating as a fluid coupling and car operating conditions change so that increased torque is demanded, the converter automatically adjusts itself to meet the demand without any manipulation of controls by the driver.

When the drive through the torque converter is reversed on deceleration or when descending grades, the converter functions as a fluid coupling to permit effective engine braking. It also functions as a fluid coupling when the car is pushed in Low range to crank the engine.

5-7 1958 BUICK VARIABLE PITCH DYNAFLOW PLANETARY GEARS AND DIRECT DRIVE CLUTCH

The 1958 Buick planetary gears and related parts provide reverse and an emergency low driving range. The direct drive clutch locks the planetary gears to provide direct drive without gear action, when 1958 Buick Variable Pitch Dynaflow Transmission is in Direct Drive (D). In Neutral (N) and Parking (P) the free turning planetary gears and disengaged clutch provide a condition in which the engine is completely disconnected from the propeller shaft and rear wheels.

Although certain parts are common to the planetary gear train and the direct drive clutch, construction details of each system will first be described separately to avoid confusion, then the combined operation of both systems to provide the various ranges will be described.

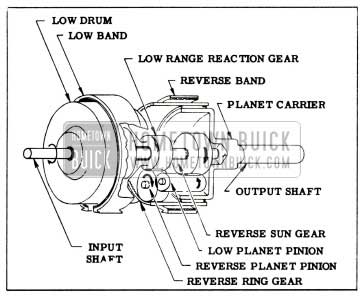

Construction of 1958 Buick Planetary Gear and Related Parts

The gears and related parts which form the planetary gear train are schematically indicated in figure 5-8. The principle elements are as follows:

1958 Buick Elements of Planetary Gear Train

- Planet carrier

- Three low planet pinions

- Three reverse planet pinions

- Reverse sun gear and input shaft

- Reverse ring gear

- Reverse band

- Low range reaction gear

- High and low drum

- Low band

The parts which control operation of the clutch and the two bands are considered to be part of the hydraulic control system, which is separately described in paragraph 5-8.

The planet carrier, which forms the principle supporting member, is mounted in bushings in the transmission case and rear bearing retainer. The 1958 Buick Variable Pitch Dynaflow Transmission output shaft, which is splined to the universal joint, is splined with the planet carrier to make a unit assembly. A bushing in gear and carrier so th.at each part can rotate independently of the other. The reverse band surrounds the reverse ring gear so that when the band is applied by the hydraulic control mechanism the ring gear will be held stationary. As explained later (subparagraph e), reverse is obtained by holding the ring gear stationary.

The three reverse planet pinions also mesh with the low range reaction gear. The reaction gear is integral with a flange which is keyed to the low drum. The input shaft passes freely through the center of the reaction gear. The low band surrounds the drum so that when the band is applied by the hydraulic control mechanism the drum and reaction gear will be held stationary. As later explained (subparagraph d), low the carrier supports the rear end of the inpu.t shaft which transmits torque into the gear set from the converter turbine. The three low planet pinions and the three reverse planet pinions are mounted separately on shafts which are anchored at both ends in the planet carrier.

The reverse sun gear, which is the driving gear, is splined to the rear end of input shaft in position to mesh with the three low planet pinions. Each low planet pinion meshes with a reverse planet pinion, functioning as an idler pinion to cause the reverse planet pinion to rotate in the same direction as the sun gear.

The three reverse planet pinions mesh with the internal-toothed reverse ring gear which is supported by the planet carrier. A bushing in the ring gear provides a bearing between the range is obtained by holding the reaction gear stationary.

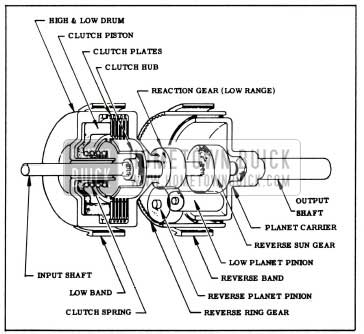

Construction of 1958 Buick Direct Drive Clutch

The 1958 Buick direct drive clutch is a hydraulically operated coupling device containing the following parts shown in figure 5-9.

1958 Buick Direct Drive Clutch and Planetary Gears

- Clutch hub

- Six internal splined clutch plates

- Six external splined clutch plates

- Low range reaction gear

- High and low drum

- Clutch piston

- Clutch spring

The clutch hub is splined to the input shaft, which passes freely through the low range reaction gear. The internal splined (faced) clutch plates mesh with splines in the clutch hub so that the plates, hub and input shaft rotate together at all times. The external splined (steel) clutch plates are placed between the internal splined plates and they engage slots in the flange of the reaction gear so that these plates can drive the reaction gear.

The high and low drum and the reaction gear flange form a housing for the clutch parts, and drum also provides a cylinder for the clutch piston. A neoprene seal located in a groove in piston and a sealing ring located in a groove in the drum hub effectively prevent escape of oil from the chamber formed between the piston and the closed end of drum. Oil may be fed into this chamber through holes in the hub of the drum.

When the 1958 Buick Variable Pitch Dynaflow Transmission is in Direct Drive (D), oil under a pressure of 90-100 psi is fed into the chamber to press the piston against the clutch plates and squeeze them together. This locks the low range reaction gear to the input shaft. In all other ranges oil pressure is not applied and the clutch spring holds the piston away from the clutch plates. The internal and external splined plates are then free of each other and cannot transmit drive to the reaction gear.

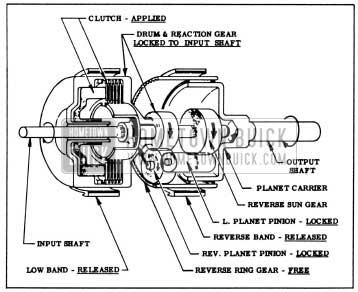

Operation of Clutch and Planetary Gears in Direct Drive (D)

In Direct Drive the input shaft and the output shaft (planet carrier) are solidly coupled so that they turn together without any gear action.

Oil pressure supplied through the hydraulic control system applies the direct drive clutch to lock the low range gear to the input shaft. Since the reverse sun gear is also locked (splined) to the input shaft both gears apply equal force to the reverse and low planet pinions, causing these pinions to lock against each other. The driving force is transmitted through the pinions and pinion shafts to the planet carrier so that the output shaft is driven at the same speed and in the same direction as the input shaft. See figure 5-10.

1958 Buick Clutch and Planetary Gears in Direct Drive

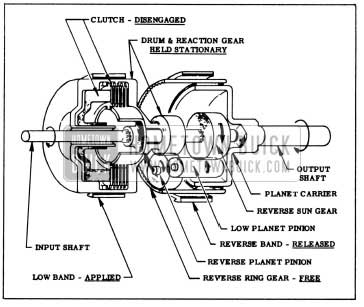

Operation of Clutch and Planetary Gears in Low (L)

In Low range the output shaft (planet carrier) turns in the same direction as the input shaft but at a reduced speed.

Oil pressure supplied through the hydraulic control system applies the low band to hold the low drum and the low range reaction gear stationary. The direct drive clutch is disengaged and the reverse band is released.

The reverse sun gear drives the low planet pinions which rotate the reverse planet pinions in the same direction as the input shaft. The reverse planet pinions are meshed with the stationary low range reaction gear; therefore, they move around this gear and exert force through the pinion shafts to rotate the planet carrier and output shaft in the same direction as the input shaft. See figure 5-11.

1958 Buick Clutch and Planetary Gears in Low

A speed reduction of 1.82 to 1 in forward motion is obtained in low range planetary gearing. When combined with the maximum torque multiplication of 3.2 to 1 available through the torque converter at low angle position of stator an overall torque multiplication of 5.82 to 1 is possible, providing starting torque considerably greater than that obtained with the conventional three speed sliding gear transmission.

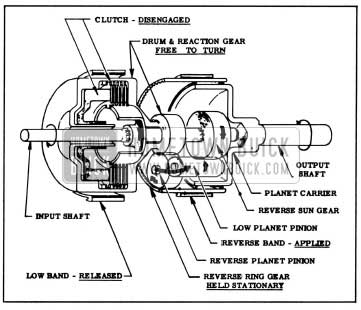

Operation of Clutch and Planetary Gears in Reverse (R)

In Reverse the output shaft (planet carrier) turns in a direction opposite to the input shaft, and at a reduced speed.

Oil pressure supplied through the hydraulic control system applies the reverse band to hold the reverse ring gear stationary. The direct drive clutch is disengaged and the low band is released.

The reverse sun gear drives the low planet pinions which rotate the reverse planet pinions in the same direction as the input shaft. The reverse planet pinions are meshed with the stationary reverse ring gear; therefore, they move around inside the ring gear and exert force through the pinion shafts to rotate the planet carrier and output shaft in a direction opposite to the input shaft. See figure 5-12.

1958 Buick Clutch and Planetary Gears in Reverse

A speed reduction of 1.82 to 1 and reverse motion is obtained in reverse planetary gearing. Combined with the maximum torque multiplication of 3.2 to 1 available through the torque converter at low angle position of stator an overall starting torque multiplication of 5.82 to 1 is possible in reverse.

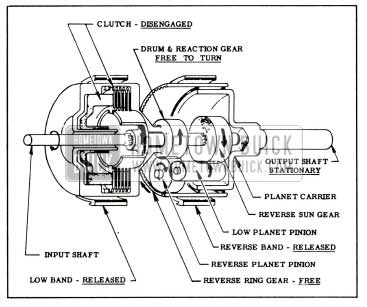

Operation of Clutch and Planetary Gears in Neutral (N) and Parking (P)

In Neutral and Parking oil pressure is cut off from the direct drive clutch so that clutch is disengaged. Pressure on both bands is also released. Both the low range reaction gear and the reverse ring gear are free to turn so that the reverse planet pinions cannot react against either gear. The pinions merely rotate without applying force to the pinion shafts; consequently the planet carrier and output shaft remain stationary. See figure 5-13.

1958 Buick Clutch and Planetary Gears in Neutral and Parking

5-8 1958 BUICK VARIABLE PITCH DYNAFLOW HYDRAULIC CONTROL SYSTEM

The 1958 Buick Variable Pitch Dynaflow Transmission is supplied with sufficient oil to keep the torque converter completely filled when in operation and to provide approximately three additional quarts for lubrication and for operation of all hydraulic controls. Two oil pumps are used to provide oil circulation and pressure and valves are used to regulate and control the oil pressure.

A shift control valve in the transmission routes oil to the controlling devices which govern operation in Direct Drive, Low and Reverse. In Neutral and Parking positions the control valve cuts off oil pressure to all controlling devices and opens the supply lines for drainage into the sump. The shift control valve is moved into position for the desired range by the driver using the shift control lever on steering column.

A valve in the high accumulator controls oil flow for operating the 1958 Buick variable pitch stator. This valve is controlled through linkage actuated by the engine throttle linkage.

The hydraulic control system performs the following functions:

- Keeps the torque converter filled with oil

- Provides lubrication to all working parts

- Applies the clutch in Direct Drive range

- Applies low band in Low range

- Applies reverse band in Reverse range

- Operates the variable pitch stator

1958 Buick Variable Pitch Dynaflow Transmission Oil Pumps

Two oil pumps of the internal gear type are used to provide oil circulation and pressure. The front oil pump, which is driven by the converter primary pump hub, is in operation whenever the engine is running. The rear oil pump, a smaller unit is driven by the 1958 Buick Variable Pitch Dynaflow Transmission output shaft and therefore operates only when the rear wheels are turning.

The front oil pump would be sufficient for all normal operation with engine running. When towing the car for some distance in Neutral, circulation of oil for transmission lubrication is required. When towing or pushing the car to start the engine oil pressure is required to engage either the low band or the direct drive clutch. Under these conditions the front pump is not operating but the rear pump is driven by the rear wheels to provide the necessary oil circulation and pressure.

The front and rear oil pumps are inter-connected by oil channels provided with check valves so that they can operate together or independently of each other. The arrangement is such that a minimum of power is used in driving the pumps. The conditions under which each pump supplies pressure are described in the following subparagraph.

Oil Pump Pressure Regulation

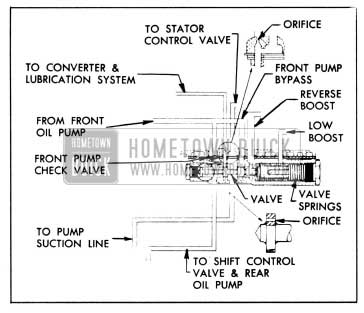

The pressure of both oil pumps is controlled by the pressure regulator valve which is contained in the same valve body which houses the shift control valve. The cylindrical regulator valve has three lands which control passage of oil through ports in valve body. Two calibrated coil springs press against the inner end of valve, and plugs retain the springs and valve in the body. See figure 5-14.

1958 Buick Oil Pump Pressure Regulator Valve

The pressure regulator valve performs the following functions:

- When either pump is running the valve opens the channel port through which oil is fed to the converter and lubrication system, and when neither pump is running the valve closes this port to prevent drainage of oil from converter.

- In Parking, Neutral and Direct Drive the valve regulates pump pressure to 100 psi.

- In Low and Reverse the valve regulates pump pressure to 200 psi.

When car is stopped and engine is not running the springs hold the valve against its retaining plug so that the second land closes the channel port leading to the torque converter. See figure 5-14.

When the engine is started in Parking or Neutral, oil from the front pump opens the pump delivery check valve and enters the regulator valve cylinder between the first and second lands of the valve. The first land of pressure regulator valve has a small orifice through which oil flows to build up pressure against the outer end of the valve.

When the pressure against outer end of valve becomes sufficient to move the valve against the springs the second land opens the port through which oil is fed to the torque converter and the lubrication system later described in subparagraph c. When the pressure reaches 100 psi, the third land of valve opens the front pump bypass port to permit excess oil to return to the pump suction line, thereby controlling the front oil pump pressure to 100 psi. See figure 5-19.

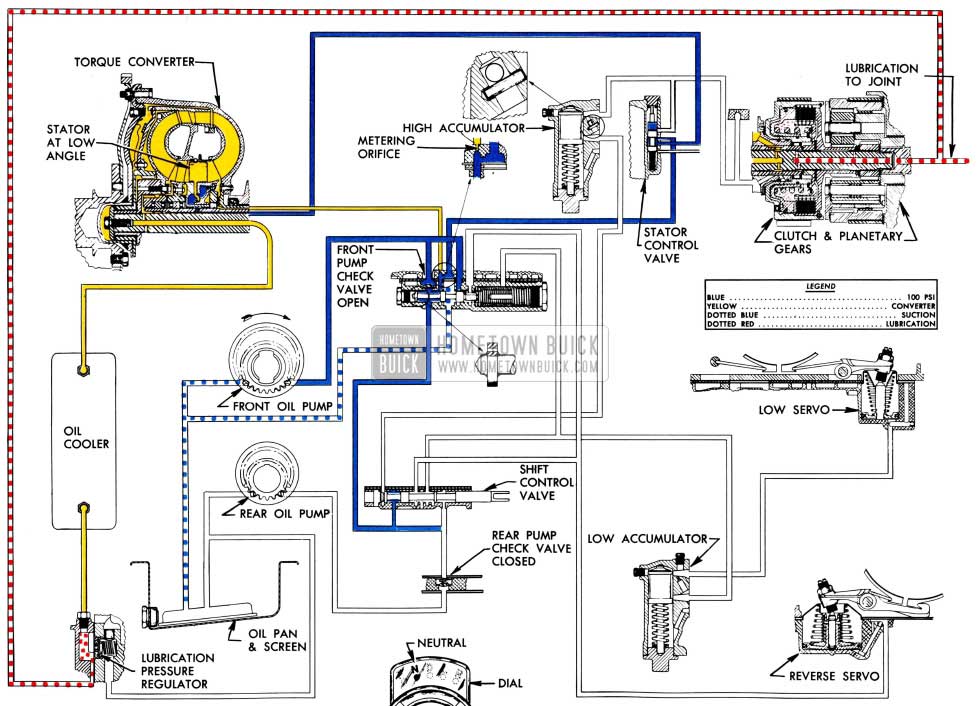

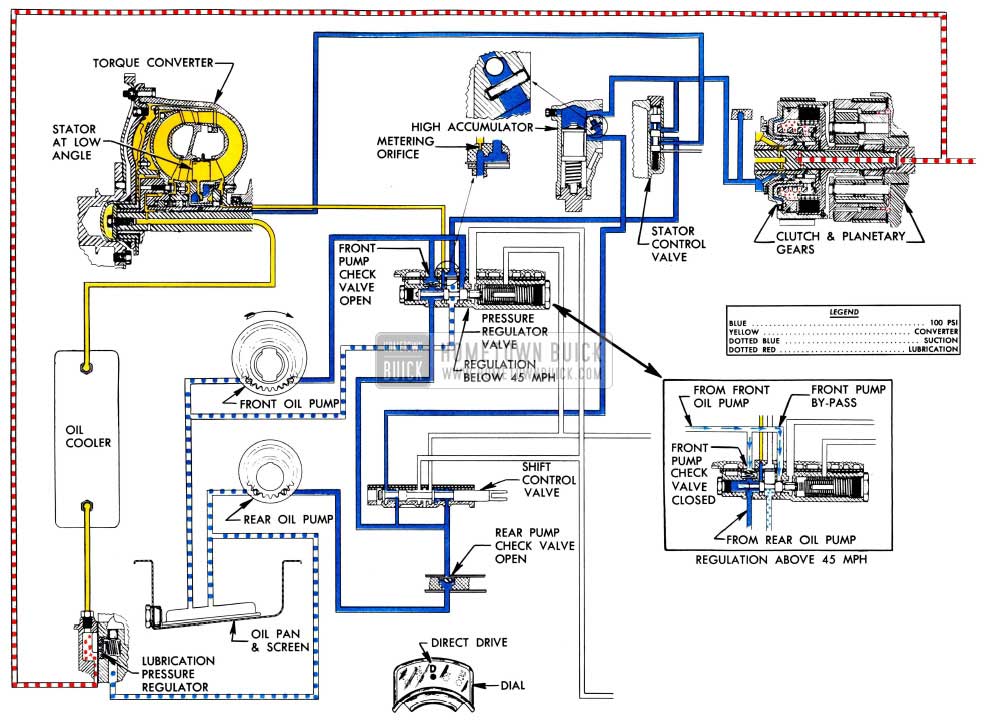

After car is in motion in Direct Drive, the rear pump develops sufficient pressure to open the rear pump delivery check valve and the rear pump then delivers oil to the channel between the regulator and control valves as shown in figure 5-20. The increased volume of rear pump causes the regulator valve to move against the springs until the second land permits excess oil to escape into the pump suction line. The combined pressure of both pumps is thereby regulated to 100 psi.

As car speed increases the increased output of the rear pump moves the regulator valve farther against the springs to increase the by-pass openings and maintain regulated pressure. As this occurs a greater amount of front pump output is by-passed until at approximately 45 MPH the entire output is by-passed. The front pump delivery check valve closes and from this point the rear pump alone supplies oil at 100 psi. See figure 5-20.

In Low the regulation of pump pressure is the same as described for Direct Drive except that the pressure is regulated at 200 psi. When in Low range position the shift control valve passes oil into the “Low Boost” chamber so that pump pressure is applied to the inner end of regulator valve. Since the inner end is 1/2 the area of the outer end of valve, pump pressure applied to both ends has the effect of cancelling or neutralizing 1/2 the area of the outer end. Pump pressure against the remaining area of the outer end must be doubled in order to balance the regulating spring load and obtain the regulation previously described. Pump pressure is thereby regulated at 200 psi. See figure 5-20.

In Reverse the regulation of front oil pump pressure is the same as described for Direct Drive when starting the car except that the pressure is regulated at 200 psi. The shift control valve passes oil into the “Reverse Boost” chamber behind the third land of regulator valve so as to boost pump pressure in the same manner as for low. Since the rear oil pump is turning in reverse direction it does not supply oil, and the closed delivery check valve prevents drainage through the rear pump. See figure 5-24.

1958 Buick Variable Pitch Dynaflow Transmission Converter Feed, Oil Cooler and Lubrication Systems

When either oil pump is running, oil flows in limited volume through the converter, oil cooler, and lubrication system.

Oil flows from the pressure regulator valve through a channel containing a restricted metering orifice to limit the volume, and enters the converter around the outside of the reaction shaft and between the stator and converter pump. All parts in the torque converter are lubricated by the oil which completely fills the converter. Oil leaving the converter enters the input shaft, flows rearward to an exit port between two oil rings, flows into the reaction shaft and then into a passage in the reaction shaft flange. See figure 5-19.

From the reaction shaft flange the oil is piped to an external oil cooler which maintains the oil temperature at a satisfactory level. The oil cooler is a water cooled heat exchanger incorporated in the lower radiator tank. Oil is piped from the cooler to a passage in the rear bearing retainer which connects with the lubrication system.

A spring loaded lubrication pressure regulator valve is located in the 1958 Buick Variable Pitch Dynaflow Transmission case adjacent to the oil inlet passage in the rear bearing retainer. This regulator valve maintains oil pressure in the lubrication system at approximately 15 psi and by-passes surplus oil to the pump suction line.

Oil for lubrication of direct drive clutch and planetary gear set enters passages in the output and input shafts just forward of the rear oil pump. The passage in output shaft also feeds oil to the rear bearing retainer bushing and universal joint. See figure 5-19.

1958 Buick Oil Flow in Neutral, Showing Converter Feed, Lubrication and Cooling

Operation of Hydraulic Controls In Neutral and Parking

In Neutral the shift control valve is in the position shown in figure 5-19. In Parking the valve is farther to the right. In both cases the valve blocks passage of oil to the clutch and band controls so that these parts are released and torque cannot be transmitted through the gear train.

In Neutral and Parking there is oil flow through the converter and lubrication system when the engine is running.

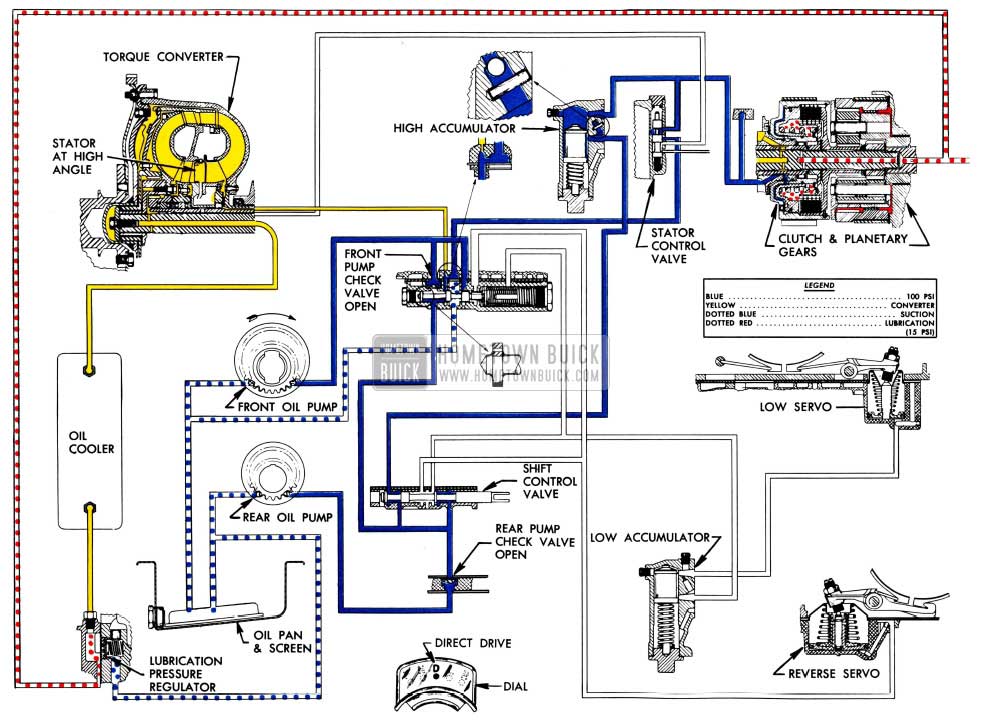

Operation of Hydraulic Controls When Shifting Into Direct Drive

As explained in paragraph 5-7, Direct Drive is obtained by applying the direct drive clutch. When the shift control lever is moved to Direct Drive (D), the control valve is moved into position to pass oil (at 100 psi) to apply the direct drive clutch. See figure 5-20.

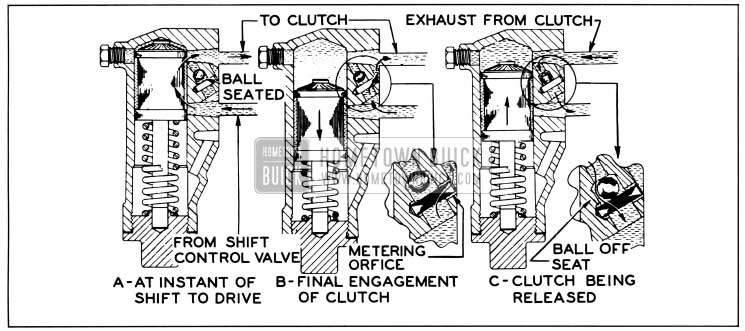

When shifting into Direct Drive a smooth but rapid engagement of the clutch is desired. This is obtained by a cushioning device called a high accumulator, which is inserted in the line between the control valve and the clutch. The accumulator permits a large flow of oil into the clutch apply chamber until clutch engagement just starts and then reduces the flow to prevent sudden, harsh engagement. Its function may be compared to that of a door check.

The high accumulator body contains a large cylinder which houses a piston and heavy coil spring, and the cylinder is closed at the lower end by a cap which has a stop pin to limit the downward travel of the piston against the spring. Lands at both ends of the piston are ground to close fits in the cylinder and the reduced diameter of piston between the lands permits passage of oil between the inlet and outlet ports when the piston is at top of cylinder. The inlet and outlet ports are also connected by a channel containing a check ball. The ball retaining pin fits in an oversize hole which provides a metering orifice for passage of oil between the inlet and outlet ports when the ball is seated to close the larger passage. See figure 5-15.

1958 Buick High Accumulator Operation

Before the shift into Direct Drive the piston is held at top of cylinder by the spring. At instant of shift oil passes through the control valve and enters the accumulator, where it flows in large volume around the piston and continues on into the clutch apply chamber. The difference in pressure holds the check ball against its seat so that no oil flows through this channel. See figure 5-15, view A.

As soon as clutch apply chamber is filled and clutch engagement begins, back pressure builds up in the accumulator to force the piston down against spring pressure. The rise in pressure as spring is compressed gives smooth final engagement of clutch. The upper land of piston passes the exit port in cylinder as the piston moves down so that passage of oil around the piston is cut off. Oil passing through the metering orifice surrounding the check ball retaining pin then builds up pressure in the accumulator to hold the piston down and to maintain the pressure required in the clutch apply chamber to insure solid engagement of clutch. See figure 5-15, view B.

When oil enters the clutch apply chamber from the high accumulator the clutch piston compresses the clutch spring and presses the clutch plates tightly together. The low range reaction gear is thereby locked to the input shaft and direct drive is obtained as previously described in paragraph 5-7.

Figure 5-20 shows the complete oil flow in 1958 Buick Variable Pitch Dynaflow Transmission in Direct Drive.

1958 Buick Oil Flow in Direct Drive-Stator at Low Angle

1958 Buick Oil Flow in Direct Drive-Stator at High Angle

Operation of Hydraulic Controls When Shifting Out of Direct Drive

When shifting out of the Direct Drive in either direction the shift control valve is moved into position to cut off oil pressure to the direct drive clutch and to open the clutch apply line for discharge into the sump. Opening the apply line to atmosphere inside the 1958 Buick Variable Pitch Dynaflow Transmission immediately relieves pressure in clutch apply chamber and the accumulator spring pushes accumulator piston upward to force oil out of accumulator. The reversed flow of oil forces the check ball off its seat so that oil can escape rapidly through that channel. The accumulator piston returns to its original position, and the clutch piston releases the clutch plates. See figure 5-15, view C.

In Reverse and Neutral the drum and piston rotate at much higher speed than the input shaft. High speed rotation would create sufficient centrifugal force in the oil remaining in the clutch apply chamber to partially engage the clutch. This would soon ruin the clutch plates. To insure complete drainage of oil from the clutch apply chamber a check ball bleed valve is placed in the drum. When the clutch is free the check ball is moved off its seat by centrifugal force and residual oil flows out of the apply chamber through the opened bleed hole. When the clutch is engaged in Direct Drive, clutch apply oil pressure forces the bleed valve check ball against its seat to prevent the escape of oil.

As oil leaves the apply chamber it creates suction in the apply line. To break this suction a check ball vent valve is placed in the apply line which opens to atmosphere inside the 1958 Buick Variable Pitch Dynaflow Transmission. When apply pressure is directed to the clutch the vent valve is closed by oil pressure to prevent escape of oil.

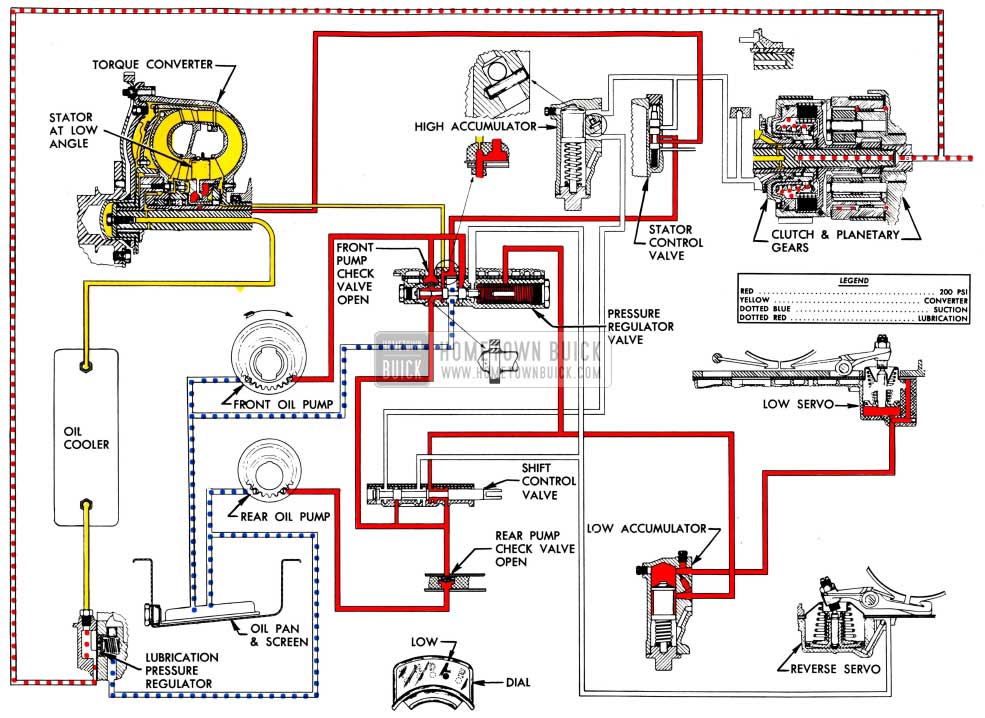

Operation of Hydraulic Controls When Shifting into Low

As explained in paragraph 5-7, Low range is obtained by applying the low band to the low drum so that the attached low range reaction gear is held stationary. When the shift control lever is moved to Low (L), the control valve IS moved into position to pass oil to the low servo which applies the low band, also to pass oil to the low boost chamber in the pressure regulator valve body, thereby increasing the apply pressure to 200 psi as previously described (subparagraph b).

The low servo consists of a piston in a cylinder contained in the servo body mounted on bottom of 1958 Buick Variable Pitch Dynaflow Transmission case. Oil entering the cylinder pushes the servo piston upward against the outer end of the band operating lever, causing the band operating lever to pivot and force the strut against one end of the low band. The other end of band butts against another strut which is held by an anchor shaft mounted in the transmission case. The resulting compression of the ends applies the band to the drum so that the drum and attached reaction gear is held stationary. See figure 5-22.

1958 Buick Oil Flow in Low Range-Stator at Low Angle

When shifting into Low a smooth but rapid engagement of the low band is desired. This is obtained by placing a low accumulator in the low servo oil pressure line. The low accumulator is similar in construction and operation to the high accumulator previously described (subparagraph e), except that a .0625″ metering orifice is drilled in the passage between inlet and outlet ports to control the rate of filling, and a check ball is not used.

Operation of Hydraulic Controls When Shifting Out of Low

When shifting out of Low, the shift control valve is moved to shut off oil supply to the low servo apply line and open this line for drainage to the sump. This also relieves the pressure in the low boost chamber in pressure regulator valve body, therefore the oil pump pressure drops to 100 psi.

With pressure relieved, the low servo spring pushes the servo piston down to force oil out of the servo cylinder and release the low band. The accumulator spring returns the accumulator piston to its original position, forcing oil from the low accumulator.

When shifting from Low to Direct Drive under load it is necessary to apply the direct drive clutch before the low band is fully released, in order to obtain a smooth transfer of power. All oil discharged from the low servo and low accumulator must pass through the .0625″ metering orifice in accumulator body until the piston upper land reaches the upper port and permits more rapid discharge of oil. The metering orifice controls discharge of oil to retard release of the low band until the direct drive clutch is applied.

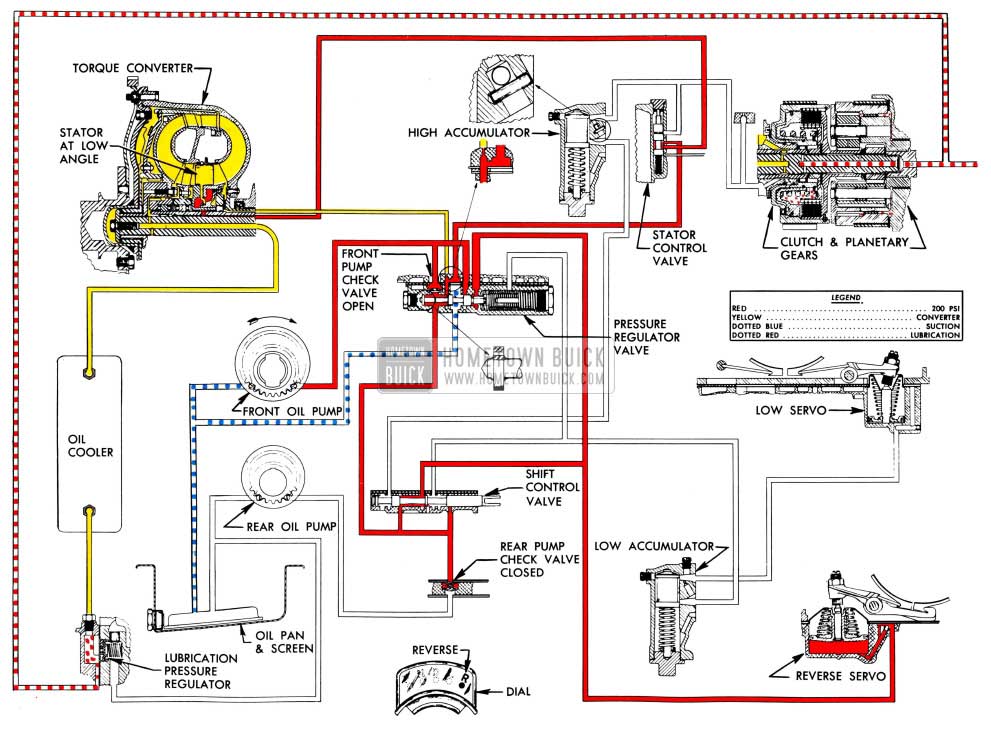

Operation of Hydraulic Controls When Shifting Into Reverse

As explained in paragraph 5-7 Reverse is obtained by applying the reverse band to hold the reverse ring gear stationary. When the shift control lever is moved to Reverse (R), the control valve is moved into position to pass oil to the reverse servo which applies the reverse band, also to pass oil to the reverse boost chamber in the pressure regulator valve body thereby increasing the apply pressure to 200 psi as previously described (subparagraph b).

Oil at 200 psi is applied directly to the reverse servo cylinder and piston in the servo body. The reverse servo piston applies pressure to one end of the reverse band through an operating lever and strut. The other end of band is held by an anchor which is secured to 1958 Buick Variable Pitch Dynaflow Transmission case by the operating lever shaft. See figure 5-24.

1958 Buick Oil Flow In Reverse-Stator at Low Angle

Oil pressure is supplied by the front pump only. The rear oil pump turns backwards, and the rear pump delivery check valve is held closed to prevent loss of oil through this pump.

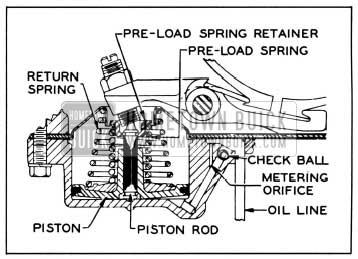

Smooth application of the reverse band is obtained through the action of the two-stage reverse servo; an accumulator is not used. Details of the reverse servo are shown in figure 5-16.

1958 Buick Reverse Servo-Sectional View

The oil line entering the servo cylinder contains a check ball, and a small metering orifice is located to bypass the check ball. The servo piston assembly consists of a piston, preload spring and spring retainer assembled on a piston rod and retained by snap rings. The piston is free to move on the rod as it compresses the pre-load spring until the hub of piston contacts the spring retainer.

When the shift to reverse is made, the resulting oil flow seats the check ball so that oil is fed into the servo cylinder through the metering orifice only. The first movement of the servo piston takes up the clearance between the band and reverse ring gear, then a pressure of approximately 70 pounds is applied to the band operating lever as the piston starts to compress the pre-load spring. Further movement of the piston increases the spring load on operating lever until the reverse ring gear stops spinning. When the piston contacts the pre-load spring retainer the full force of oil pressure is solidly applied to the operating lever to hold the band tightly clamped around the reverse ring gear. The feed through the metering orifice and the cushioning effect of the pre-load spring increases the time of applying the reverse band so that smooth engagement is obtained.

When the shift out of reverse is made, the check ball in apply line is lifted off its seat, permitting a fast discharge of oil from the servo cylinder. The compressed servo piston return spring pushes the servo piston down to effect quick release of the reverse band.

Operation of Hydraulic Controls When Shifting Variable Pitch Stator

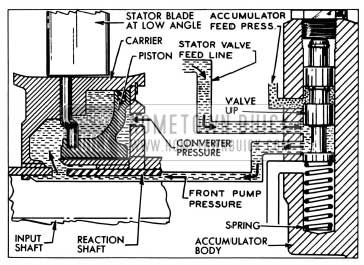

The 1958 Buick variable pitch stator control valve, incorporated in the high accumulator housing is supplied with oil at front pump pressure up to approximately 45 m.p.h. at which point the rear pump takes over. Normally this valve is held upward by a spring so that oil can pass through into the stator carrier on front side of the piston. Since this pressure is greater than the converter charging pressure on rear side of piston, the piston moves rearward to hold the stator blades in the low angle “cruising” position. See figure 5-17.

1958 Buick Stator in Low Angle Position

This will give the converter a low stall speed and torque multiplication of 3.2 to 1, providing a solid drive feel for all normal operating conditions.

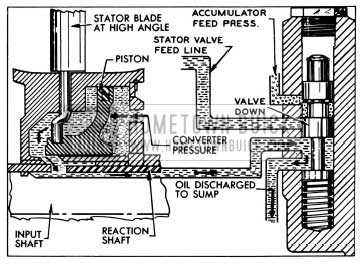

When the accelerator pedal is pressed to floor mat the throttle control linkage actuates other linkage connected to the stator control valve so that the valve is pushed down, thereby shutting off oil pressure to the stator and opening a passage to discharge oil from front side of the piston. Converter charging pressure on rear side of stator piston then moves the piston forward, which rotates all stator blades approximately 75 degrees from the low angle position. See figure 5-18.

1958 Buick Stator in High Angle Position

This high angle “performance” position will give the converter a higher stall speed and torque multiplication of 3.5 to 1, providing improved acceleration and pulling power under load. The transitions from low angle to high, or high angle to low are very smooth and devoid of bumps.

Leave A Comment

You must be logged in to post a comment.