SECTION 3-C 1952 BUICK FUEL SYSTEM ADJUSTMENTS AND REPLACEMENTS – EXCEPT IN PUMP AND CARBURETOR ASSEMBLIES

3-7 1952 BUICK AIR CLEANER AND GAS FILTER SERVICE

1952 Buick Air Cleaner Service

An air cleaner with a dirty element, or with oil that is dirty, too heavy, or too high in the sump, will restrict the air flow to the carburetor and cause a rich mixture at all speeds. The device will not properly remove dirt from the air and the dirt entering the engine will cause abnormal formation of carbon, sticking valves, and wear of piston rings and cylinder bores.

Regular cleaning of the element and sump and filling sump with clean oil at 5000-mile intervals, or more frequently in dusty territory, is necessary to prevent excessive engine wear and abnormal fuel consumption. The procedure for cleaning and refilling the air cleaner is given under Lubricare Instructions, paragraph 1-2.

Cleaning 1952 Buick Gasoline Filter

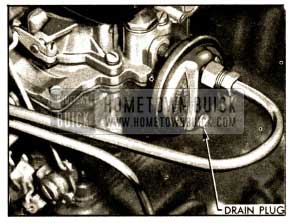

The 1952 Buick gasoline filter located at carburetor inlet collects dirt and water. The drain plug at the bottom of the inlet side of filter should be removed occasionally to drain out the accumulation of dirt and water. See figure 3-5.

1952 Buick Moraine Gasoline Filter

When a thorough cleaning is required, remove the filter, remove the drain plug and agitate the filter in Bendix Metaclene or its equivalent. Direct air stream through the outlet port of filter to force dirt from the inlet side of filtering disk. Rinse filter in kerosene, distillate, or white gasoline and again direct air stream through the outlet port. Install drain plug and reinstall filter.

1952 Buick Fuel Pump and Carburetor Gasoline Strainers

A fine mesh strainer or screen is located in the inlet passage of the Series 40-50 fuel pump, and it may be reached by removing the hex plug and gasket from the fuel pump cover. A screen is also located in the bowl of the Series 70 fuel pump. This screen may be reached by removing the bowl screw and gasket, and then the bowl and gasket from the fuel pump. It is advisable to remove and clean these screens periodically (twice a year) to eliminate any dirt and water that may have accumulated at fuel pump inlet.

A fine mesh strainer is located in the carburetor inlet. This strainer should seldom require cleaning because of the fuel pump filter and the gasoline filter which precede it in the gasoline supply line. This strainer should be inspected however, if fuel supply at carburetor inlet is adequate but carburetor operation indicates lack of fuel.

On 1952 Buick Carter carburetors the inlet strainer is located under the brass nut above the fuel inlet. On the 2-barrel carburetor it is necessary to remove the air horn in order to remove the nut and strainer. On all Stromberg carburetors it is necessary to remove the carburetor in order to reach the strainer, which is held in the inlet port in air horn by a small wire retainer clip.

3-8 1952 BUICK THROTTLE LINKAGE ADJUSTMENT

The 1952 Buick throttle linkage must work freely and be adjusted so that the accelerator pedal can move the throttle valve smoothly from fully closed to wide open positions. When pedal is pressed down against floor mat the throttle must fully open to the throttle stop on carburetor, and the choke unloader must be operated in the wide open, position. When pedal is released, the throttle must close against the throttle stop screw; on Dynaflow cars the dash pot must govern the closing to prevent stalling or rolling of the engine.

Before making the following adjustments make sure that accelerator pedal is securely fastened to floor pan and rod does not bind in hole through floor mat.

1952 Buick Throttle Linkage Adjustment – Synchromesh Transmission Cars

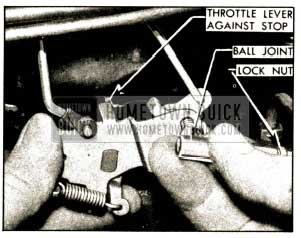

- Disconnect the throttle operating rod ball joint from the 1952 Buick throttle lever and open the throttle valve to wide open position against its stop.

- While a second man presses accelerator pedal firmly against the floor mat, which must be in place, adjust the ball joint on throttle operating rod so that the screw will just enter the hole in throttle lever. On Carter Carburetor the upper hole in throttle lever is used. See figure 3-6.

1952 Buick Throttle Rod Adjustment-Synchromesh

1952 Buick Throttle Linkage and Dash Pot Adjustment – Dynaflow Drive Cars

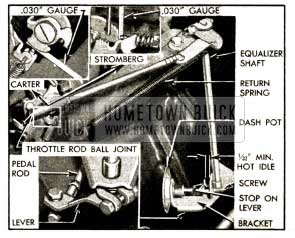

- With engine hot and idling at 450 RPM, check clearance between the stop on lever at lower end of equalizer shaft and the shaft lower bracket. See figure 3-7. If clearance is less than 1/32″, adjust throttle operating rod at ball joint to obtain a minimum of 1/32″ clearance. Tighten lock nut.

1952 Buick Throttle Linkage and Dash Pot Adjustment

3-9 1952 BUICK EXHAUST MANIFOLD VALVE SERVICE

Freeing up Sticking Valve

Carbon or lead salt deposits around the valve shaft may cause the valve to stick or become sluggish in operation. A valve sticking in the open position will cause slow engine warm up, excessive spitting and sluggish engine operation when cold. A valve sticking in the closed position will cause overheating, loss of power, and hard starting when the engine is hot, and may also cause warped or cracked manifolds. Sticking in either position will adversely affect fuel economy.

If the valve shaft is sticking or frozen in the valve body, free it up by tapping on the ends with a light hammer, and by rotating the counterweight. Penetrating oil or kerosene may be used to aid in freeing the shaft.

When the valve shaft is free, apply a mixture of kerosene and powdered graphite liberally to the shaft bearing; the mixture to be composed of 2% ounces of powdered graphite to 1 pint of kerosene. Lubrication of shaft every 1,000 miles is specified in Lubricare Instructions (par. 1-1).

Checking 1952 Buick Manifold Valve Thermostat Setting

The setting of the 1952 Buick exhaust manifold valve thermostat may be checked when the engine is at room temperature of approximately 70°F. Unhook the outer end of thermostat from anchor stud on the valve body and hold the valve in the closed (heat on) position. To bring the end of thermostat to the anchor stud will then require approximately 1/4, turn wind-up of the thermostat.

The thermostat is not adjustable and should never be distorted or altered in any way as this will affect its calibration. If the thermostat does not have the proper setting, or is damaged, it should be replaced.

Adjusting 1952 Buick Manifold Valve Anti-Rattle Spring

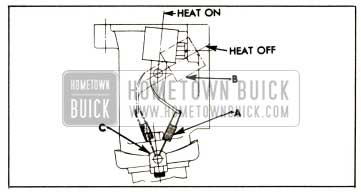

The valve anti-rattle spring must be adjusted so that the valve cannot flutter and chatter against the inside of valve body in either the closed (heat on) or open (heat off) positions. These positions can be felt by moving the counterweight by hand, and adjustment can be made with engine hot or cold.

On Series 70, the anti-rattle spring tension is adjusted by loosening the attaching screw and moving the anchoring bracket. On Series 40-50, the spring tension is adjusted by bending the anchoring bracket “C.” See figure 3-8.

1952 Buick Valve Anti-Rattle Spring Adjustment-Series 40-50

Adjustment so that the valve has sufficient clearance to prevent rattle in the closed position will usually be correct for the open position also. Clearance equal to 1/16″ to 1/8″ movement at the extreme end of counterweight is correct.

3-10 1952 BUICK CARBURETOR AND AUTOMATIC CHOKE ADJUSTMENTS

Carburetor adjustment should not be attempted until it is known that all items affecting engine Ignition and Compression are in good order, as outlined in paragraph 2-9. Any attempt to adjust or alter the carburetor to compensate for faulty conditions elsewhere in items affecting engine performance will result in reduced fuel economy and overall performance.

The two idle needle valves and the throttle stop screw are the only external means provided for adjusting the carburetor for engine performance. The idle needle valves control the idle or low speed system of the carburetor; all adjustments or calibrations affecting the high speed, power, and accelerating systems are accomplished during assembly of the carburetor.

Initial Setting of Idle Needle Valves and Throttle Stop Screw

- With engine stopped, turn both idle needle valves clockwise until they are lightly seated. Forcing valves hard against seats will score valves and seats and ruin them for proper adjustment.

- On Carter carburetor, turn each valve “OUT” (counterclockwise) one full turn. On Stromberg 2-barrel carburetor, turn each valve “OUT” 1 1/2 turns. On Stromberg 4-barrel carburetor, turn each valve “OUT” 1 1/8 turns. These settings provide an average starting adjustment.

- Back off throttle stop screw and hold fast idle cam in HOT (choke open) position so that throttle valves are fully closed.

- Turn throttle stop screw “IN” (clockwise) until it just contacts arm on throttle lever (Carter) or lowest step of fast idle cam (Stromberg), then turn stop screw “IN” one complete turn. This setting will give an engine idling speed of approximately 450 RPM.

Final Adjustment of Idle Needle Valves and Throttle Stop Screw

- With throttle stop screw and idle needle valves at the initial settings described above (subpar. a), start the engine and run it until it is at normal operating temperature.

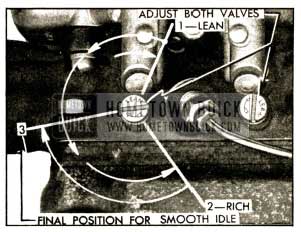

- With engine at normal operating temperature and idling at 450 RPM, adjust one needle valve at a time (fig. 3-9) to provide smooth idle, as follows:

1952 Buick Adjustment of Idle Needle Valves

- Slowly turn needle valve “IN” (clockwise) until engine just begins to lag or run irregularly because of lean mixture.

- Slowly turn needle valve “OUT” until engine just begins to “roll” or “gallop” because of rich mixture.

- Slowly turn needle “IN” just enough to provide the smoothest engine operation.

- Repeat this same procedure on the other needle valve.

Final adjustment of the carburetor idle needle valves also may be made with the aid of a combustion tester, tachometer, or vacuum gauge. When such instruments are used, be sure they are in good condition and are used in accordance with the instructions of the manufacturer.

Regardless of the methods or instruments used for making adjustment s in the shop, the correctness of adjustment should be finally checked by a road test for smoothness at idling speed, power on acceleration, and freedom from sluggishness or fiat spots throughout entire speed range.

Checking Float Bowl Level

The sight hole in the float bowl may be used to check for proper fuel level in the bowl on all carburetors except the Carter 4-barrel carburetor. On this carburetor, the sight holes should be used only to check the float action.

With engine idling at normal operating temperature, remove plug from sight hole. The fuel will be just high enough to wet the threads at lower side of sight holes if the float is correctly adjusted. Securely install plug in sight hole after checking fuel level.

1952 Buick Automatic Choke Adjustments

The 1952 Buick choke thermostat must be correctly adjusted in order to provide easy starting and good performance of engine during warm-up.

When 1952 Buick choke thermostat is cold and throttle is opened to release the fast idle cam, the thermostat should move choke valve to fully closed position. The cold engine should start readily, idle without loading or rolling, and should accelerate smoothly during the warm-up period while the choke is in operation.

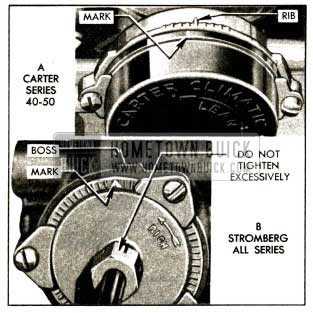

The choke thermostat is calibrated to give satisfactory performance with regular blends of fuel when it is placed at the standard factory setting (fig. 3-10), as follows:

1952 Buick Choke Thermostat Settings

Carter, Series 40-50 = 1 point rich

Carter, Series 70 = At index rib

Stromberg, all series= At index boss

When it is necessary to adjust the thermostat loosen the housing or cover attaching screws and turn as required. On Stromberg choke it is also necessary to loosen the heat pipe connection to turn the cover. When tightening heat pipe connection after adjustment do not use excessive pressure, which may change position of thermostat cover.

Thermostat settings other than standard should be used only when the car is habitually operated on special blends of fuel which do not give satisfactory warm-up performance with the standard setting. A “Lean” setting may be required with highly volatile fuel which produces excessive loading or rolling of engine on warm-up with the standard thermostat setting. A “Rich” setting should be used only when excessive spitting occurs on engine warm-up with the standard thermostat setting. When making either a “Lean” or “Rich” setting, change one point at a time and test results with engine cold, until the desired performance is obtained.

If the engine operates on fast idle too long after starting or else moves to slow idle too soon, or the choke unloader does not operate properly, check the fast idle and choke unloader adjustments as described in paragraph 3-20 (Carter) or paragraph 3-29 (Stromberg).

3-11 REMOVAL AND INSTALLATION OF 1952 BUICK CARBURETOR

Removal of 1952 Buick Carburetor

- Remove 1952 Buick air cleaner and silencer.

- Disconnect throttle rod, accelerator vacuum switch wires, choke upper heat pipe, vacuum spark control pipe, and gasoline pipe.

- Remove gasoline filter from carburetor, then remove carburetor and gasket from manifold.

Installation of 1952 Buick Carburetor

- Make sure that carburetor gasket is in good condition, then install carburetor on intake manifold.

- Clean the gasoline filter (par. 3-7), install it on carburetor, and connect the gasoline pipe. Connect the vacuum spark control pipe.

- Connect the choke upper heat pipe to choke housing (Carter) or thermostat cover (Stromberg). Avoid excessive tightening which may change the position of cover and affect thermostat setting.

- Connect and adjust throttle linkage as described in paragraph 3-8.

- Connect the accelerator vacuum switch wires and check switch timing as described in paragraph 10-33.

- Install air cleaner and silencer.

- Adjust carburetor as described in paragraph 3-10.

3-12 REPLACEMENT OF 1952 BUICK INTAKE AND EXHAUST MANIFOLDS

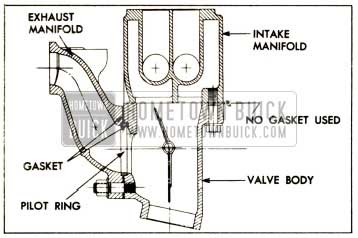

When working on 1952 Buick intake and exhaust manifolds it must be understood that both manifolds must be attached to the valve body and to the cylinder head in such manner that slippage can take place at the joints to compensate for differences in rate of expansion and contraction of the several parts due to heat. This is necessary because the parts do not have the same temperature under all operating conditions.

The assembly and method of attachment of these parts have been designed to avoid leakage of joints while permitting the required slippage. If attaching bolts and nuts are not tightened in proper sequence or are tightened excessively, warpage, leaking joints or cracked manifolds will result.

When leakage occurs at a manifold joint the condition can usually be corrected by proper adjustment of bolts and stud nuts without removing or replacing parts. Do not attempt correction by simply tightening bolts or nuts at point of leakage. Instead, loosen all manifold to valve body and cylinder head bolts and nuts, allow parts to cool to shop temperature, then tighten bolts and nuts to specified torque in the sequence given in step 5 below.

The following assembly and installation procedure should be used when replacing either manifold or the valve body. Manifolds should never be removed while engine is hot because warpage is liable to occur.

- On Series 40-50, install the valve body on the exhaust manifold with a new ring gasket in pilot ring recess in body and a new gasket between body and manifold; make sure that pilot ring is in place. See figure 3-11. Leave attaching stud nuts snug but not tight.

1952 Buick Sectional View of Joints Between Valve Body and Manifolds-Series 40-50

The individual intake manifold gaskets are centered and the branches of the intake manifold are aligned with the intake ports in cylinder head by pilot rings installed at each joint.

- 1952 Buick exhaust manifold gaskets are not used. In production, a special compound is used at joints between manifold and cylinder head, and original manifold may be reinstalled without using additional compound. When a new manifold is installed, however, coat the joint surfaces with a thin fluid mixture of graphite and oil.

- Tighten bolts and nuts in the following sequence, using a torque wrench; avoid excessive tightening.

- Tighten manifold to cylinder head stud nuts to 25-30 ft. lbs. torque.

- Tighten exhaust manifold to valve body stud nuts to 25-30 ft. lbs. torque.

- Tighten intake manifold to valve body bolts to 15-20 ft. lbs. torque.

3-13 REPLACEMENT OF 1952 BUICK GASOLINE TANK OR FILLER

When removing 1952 Buick gasoline tank, disconnect feed pipe from gasoline gauge pipe, support the tank while disconnecting support straps at rear ends, then lower tank far enough to disconnect the wire from gasoline gauge.

When installing gasoline tank by reversing procedure for removal, make sure that all road dirt is cleaned from 1952 Buick gasoline gauge and wire terminal; also make sure that wire is securely attached to gauge and that insulation is folded over the terminal and snapped over the wire.

An accumulation of road dirt around the gauge terminal may permit an electrical leak that will affect the accuracy of the gauge. Insulating strips must be located between the tank and the upper supports on body.

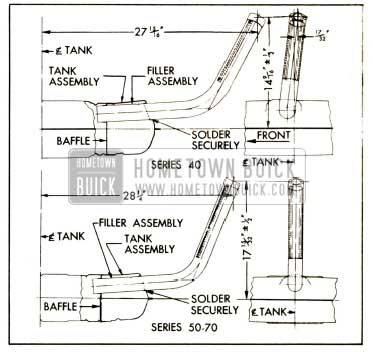

The 1952 Buick gasoline tank and the filler are furnished separately so that they may be replaced if damaged. After unsoldering the old parts, the new filler should be installed in gasoline tank in accordance with the dimensions given in figure 3-12. Joints must be thoroughly soldered and should be tested for leaks with gasoline before installing gasoline tank.

1952 Buick Location Dimensions for Installing Gasoline Tank Filler

Leave A Comment

You must be logged in to post a comment.