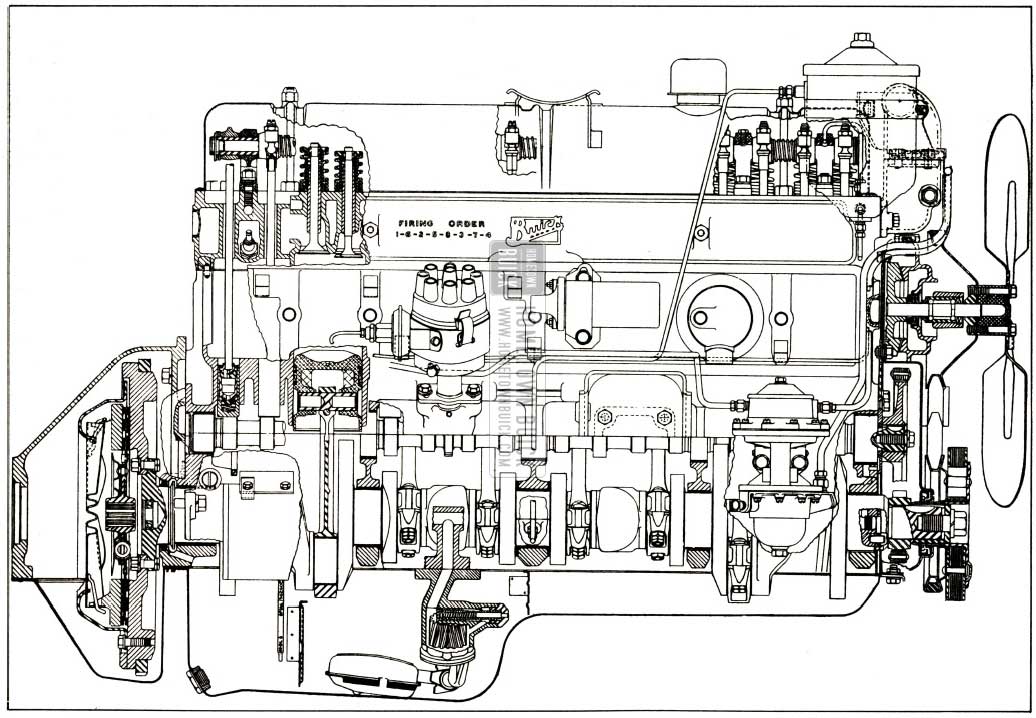

1952 Buick Engine Side Sectional View

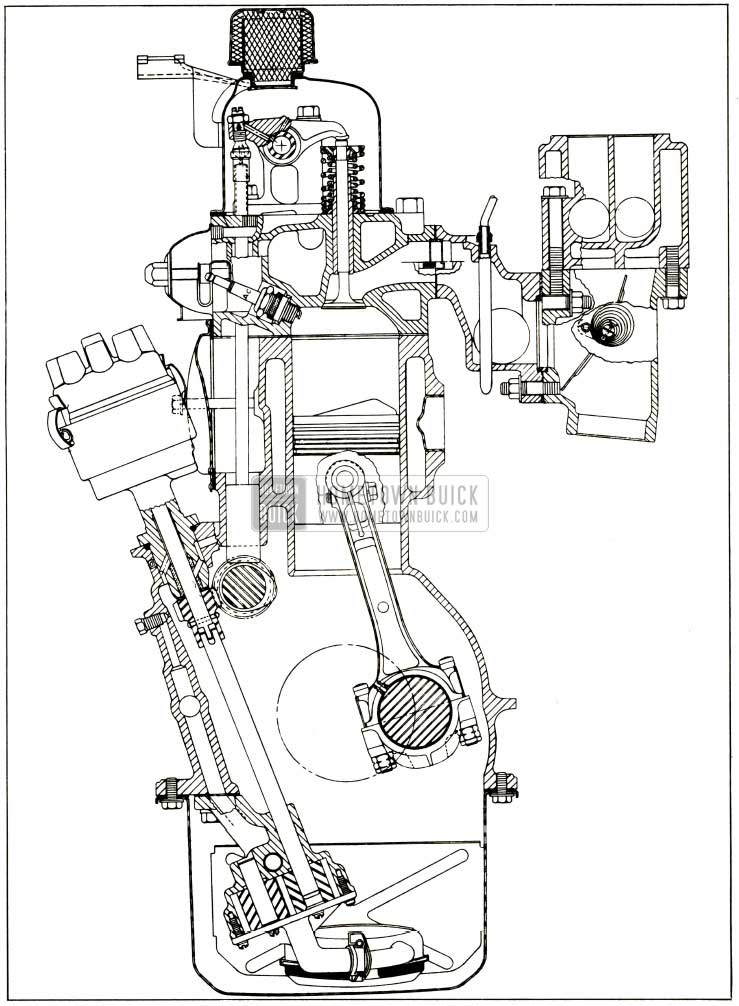

1952 Buick Engine End Sectional View

SECTION 2-B 1952 BUICK ENGINE DESCRIPTION

2-4 1952 BUICK ENGINES AND MOUNTINGS

Engines in Each Series

The 8-cylinder, in-line, valve-in-head engines used in Series 40-50 and Series 70 are of the same general design and external appearance, differing principally in bore and stroke, power, and dimensions of parts. The bore, stroke, piston displacement, compression ratio and horsepower of all engines are given under Engine General Specifications (par. 2-2).

The smaller engine used in Series 40-50, designated “F 263,” differs from the larger engine used in Series 70 in having all crankshaft bearings of the same diameter from front to rear. It also differs from the larger engine in having the piston pins offset % 6″ and the crankshaft offset lj8″ toward the camshaft side from the centerline of the cylinder bores.

“F 263” engines have the following variations in regard to transmission and series applications:

- All Dynaflow engines use hydraulic valve lifters which do not require valve lash adjustment.

- Series 50 synchromesh engines use hydraulic valve lifters.

- Series 40 synchromesh engines use plain sleeve valve lifters with adjustable valve lash.

- All synchromesh engines use a thick Steelbestos cylinder head gasket; all Dynaflow engines use a thin steel gasket to provide a higher compression ratio.

- Synchromesh engine crankshafts, flywheels, and flywheel housings are different from the Dynaflow engine parts (see par. 2-5 d).

Series 70 engines do not have any variations since only the Dynaflow transmission is used in this series. These engines are equipped with hydraulic valve lifters.

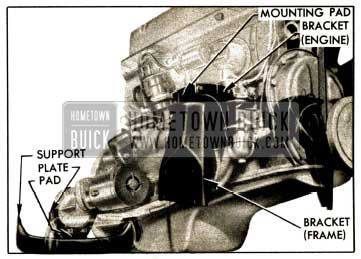

1952 Buick Engine and Transmission Mountings

The 1952 Buick engine and transmission assembly is supported at three points on “Controlled Frequency” mountings. See figure 2-3.

1952 Buick Engine and Transmission Mountings

Special synthetic rubber pads having the required friction characteristics are used to provide controlled damping properties.

The front 1952 Buick engine mounting pads are located on opposite sides of the engine near the center, fore and aft, and approximately midway between top and bottom of the cylinder crankcase. The mounting pads are fastened between engine mounting brackets extending upward from the car frame and brackets extending outward from the crankcase. The front mountings are designed to support the weight of the engine and control its torsional characteristics.

The rear (transmission) mounting is composed of two parts; a mounting pad to support a portion of the weight of engine and transmission assembly, and a thrust pad to take the drive thrust from the rear wheels. The mounting pad is located between the transmission rear bearing retainer and the transmission support on car frame. The thrust pad is located between the rear edge of transmission support and a thrust plate extending downward from the rear end of transmission rear bearing retainer. Steel shims are used to take up all clearance between the thrust pad and transmission support.

2-5 1952 BUICK ENGINE CONSTRUCTION

1952 Buick Cylinder Crankcase, Cylinder Head and Gaskets

The 1952 Buick cylinder block and crankcase are cast integral to form the cylinder crankcase. This construction, together with liberal reinforcing ribs also cast integral, provides maximum rigidity with a minimum size and weight.

The 1952 Buick cylinders are precision bored and double honed. The honing operations are controlled to leave minute pockets in the cylinder walls which are, in effect, small oil reservoirs which provide efficient piston lubrication.

When one or more bores in a cylinder crankcase cannot be properly finished to the nominal size, all bores are finished to .010″ oversize and are fitted with a .010″ oversize pistons and rings. This practice is quite general in the automotive industry and engines having such cylinder crankcases are not to be considered as special or other than production standard. These engines are identified for service purposes by a dash mark about 1/4″ long stamped directly following the engine number.

The detachable one-piece cast iron cylinder head contains the combustion chambers which are cast in place. The cylinder head mounts the overhead valve mechanism, spark plugs, intake and exhaust manifolds, and is attached to the cylinder crankcase by alloy steel bolts.

Series 40-50 synchromesh and Series 70 engines use Steelbestos cylinder head gaskets, which are .075″ thick in Series 40 and .050″ thick in Series 50-70. Series 40-50 Dynaflow engines use sheet steel head gaskets .015″ thick. To insure a tight seal, the sheet steel gaskets are crimped around the edges of all openings where leakage might occur.

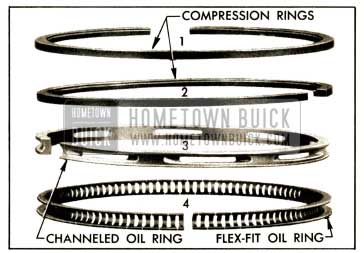

1952 Buick Pistons, Pins, and Rings

1952 Buick pistons are Anodized aluminum alloy. All 1952 Buick pistons have full skirts, are cam ground, and have four piston rings above the piston pin, Series 40-50 aluminum pistons have two transverse slots in bottom ring groove; Series 70 pistons have slots in skirt below bottom ring groove. All Series 40-50 pistons have the pins offset 1/16″ toward camshaft side; Series 70 pins are on centerline of piston. See figure 2-4.

1952 Buick Series 40-50 and Series 70 Pistons

Two bosses cast inside the piston skirt below piston pin bosses provide points at which metal is removed as required during production in order to bring the piston within the specified weight limit. Standard and oversize pistons are held to the same weight limit so that engine balance is not affected by installation of one or more oversize pistons.

The 1952 Buick piston pin bosses are diamond bored to form bearings for the piston pins. The piston pins float in the pistons and are held stationary in connecting rods by clamp bolts. A notch is ground at the middle of each pin for the clamp bolt, and the pin is solid at this point to prevent distortion.

The 1952 Buick piston head is specially shaped with a hump on one side and a rounded depression on the camshaft side. This unusual shape combined with the valve-in-head design forms a combustion chamber in which the fuel-air charge is compressed in the form of a flattened ball at the point of ignition. This “Fireball” design regulates the burning of the fuel-air charge and smooths out the power impulses. See figure 2-4.

The 1952 Buick compression rings in the two upper grooves of piston are distinguished by a small groove (on some rings a bevel) cut around the inner edge on one side. This groove (or bevel), which must be on top side of ring when installed, permits the ring to warp very slightly in the groove so that only the lower outer edge contacts the cylinder wall to aid in controlling oil during light duty operation. Under heavy duty operation the force of explosion flattens the ring and pushes it outward to provide heavier contact with the cylinder wall and insure an effective compression seal. See figure 2-5.

1952 Buick Piston Rings

The ring used in the third groove from top of piston is a conventional channeled type oil ring with oil return slots cuts through the channeled section. Oil passing through these slots returns to the crankcase through holes drilled in the piston. The narrow lands on this ring provide oil control and permit rapid wear in during the break-in period.

The ring used in the fourth groove from top of piston is designated as the “Flex-Fit” oil ring. The name was derived from the shape of the ring and its extreme flexibility. The ring is made from strip steel and is composed of segments which are joined at the inner edge of ring and separated by narrow slots in the wiping edges. This flexible construction permits perfect contact between the piston ring and the cylinder wall. Oil passing through the inner slots returns to the crankcase through holes drilled in the piston in Series 70, or through the transverse slots in Series 40-50.

The compression rings and the “Flex-Fit” rings are coated to aid in the seating of the rings and diminish the possibility of any scuffing or unnecessary wear during the break-in period.

1952 Buick Connecting Rods

1952 Buick connecting rods are heat-treated steel drop forgings of 1-beam section. Rods are forged with sufficient metal on bosses at both ends so that metal can be removed as required to secure correct weight and balance during manufacture.

The upper boss of connecting rod is bored, slotted, and tapped to receive and clamp the piston pin. The lower end and cap of rod are accurately machined to receive the bearings. No shims are used between rod and cap as bearings are precision bored and replaceable.

The cap is attached to the rod with two special diameter ground bolts to insure correct alignment; bolts are provided with hex nuts and pal nuts. A small oil hole is drilled through the bearing and flange of rod to provide lubrication to cylinder walls on the heavy thrust (camshaft) side.

Crankshaft, Bearings, Flywheel and Balancer

The 1952 Buick crankshaft is counterbalanced by weights forged integral with crank cheeks, and is both statically and dynamically balanced during manufacture. A flange forged integral with rear end of shaft supports the flywheel which is separately balanced during manufacture.

The 1952 Buick crankshaft in engines used with Dynaflow Drive are not interchangeable with crankshafts in engines used with synchromesh transmission. The difference is in the shape of the flywheel flange and the counterbore in rear end of shaft.

The crankshaft is supported in the cylinder crankcase by five bearings. In Series 70 engines the crankshaft journals and the bearings are stepped up in diameter, from front to rear. In Series 40-44-50 engines the journals and bearings are the same diameter from front to rear.

Full precision crankshaft bearings are used in all engines. The bearings are made from Durex-A material having superior fatigue qualities. The babbitt lining is bonded to the steel back of the bearing by a fine textured nickel copper matrix which gives continuous support to the bearing metal. No shims or other means of adjustment are required with these bearings as they are held to very close limits on size.

Flywheels used with synchromesh transmission are cast iron, machined to form a driving face for the clutch plate. Flywheels used with the Dynaflow transmission are flexible steel stampings to which the converter primary pump is bolted. Both type flywheels carry a ring gear for cranking the engine.

A flywheel type harmonic balancer is mounted on the front end of crankshaft to dampen torsional vibration. The hub of the balancer is keyed to the crankshaft and retained by a clamp bolt threaded into the end of crankshaft. A pulley incorporated in the balancer assembly drives the faJ1, water pump, and generator through a belt.

1952 Buick Camshaft and Valve Mechanism

The forged steel 1952 Buick camshaft is supported in the cylinder crankcase in five steel-backed babbitt-lined bearings and is driven from the crankshaft by a silent chain. The camshaft actuates the overhead valves through lifters, push rods, and rocker arms.

The 1952 Buick valve lifters operate in guide holes reamed in crankcase above the camshaft. Series 40 synchromesh engines use plain sleeve type valve lifters, and the ball studs in rocker arms are used to adjust valve lash. Series 40 Dynaflow and all Series 50-70 engines use the self-adjusting hydraulic valve lifters described in subparagraph f below.

In all engines having hydraulic valve lifters, the upper and lower ends of each push rod have centrally drilled oil holes, and the upper end is counterbored to form a shroud around a bleed hole drilled in the push rod tube. In engines having plain valve lifters the oil hole is not drilled in push rod upper ends, therefore oil does not enter the push rods; these ends are copper finished for identification.

The 1952 Buick rocker arms pivot on a tubular steel shaft which is supported on the cylinder head by eight brackets. Each rocker arm has a drilled oil passage extending from its bearing to the threaded ball stud hole. The ball stud has a groove and drilled hole for conducting oil to the push rod upper end.

Inlet valves have streamlined heads and exhaust valves have mushroom heads, all ground for 45 degree seats in cylinder head. Each valve is closed by two coil springs, and is locked to the valve spring cap by split conical keys.

1952 Buick Hydraulic Valve Lifters

Series 40 Dynaflow and all Series 50-70 engines use hydraulic valve lifters. In addition to its normal function of a cam follower, each hydraulic valve lifter also serves as an automatic adjuster which maintains zero lash in the valve operating linkage under all operating conditions. By eliminating all lash in the operating linkage and also providing a cushion of oil to absorb operating shocks, the hydraulic valve lifter promotes quiet valve operation. It also eliminates the need for periodic valve adjustment to compensate for wear of parts.

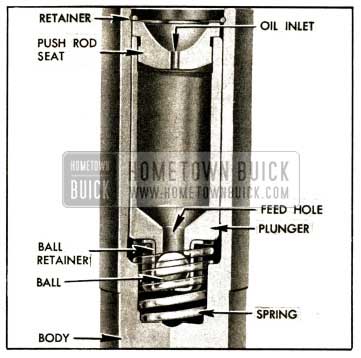

1952 Buick Hydraulic Valve Lifter, with Quarter Section Cut Out

As shown in figure 2-6, all parts of a hydraulic lifter are housed in the body, which is the cam follower. The body and the plunger are ground to very close limits, then each plunger is selectively fitted to a body to assure free movement with the least possible clearance. The push rod seat is free to move with the plunger in the body and, as its name implies, it provides a spherical seat to support the lower end of the push rod. A hole drilled in the push rod seat permits oil to enter the plunger and a feed hole in the plunger permits oil to flow down into the chamber below the plunger. The check ball at lower end of this feed hole is held in place and limited to a travel of .004″ to .008″ by the ball retainer which is pressed against the plunger by the plunger spring. The plunger retainer prevents the spring from pushing the parts out of the body when the lifter assembly is not installed in engine.

When hydraulic valve lifters are installed in an engine, each lifter is placed on the camshaft base circle (off the cam lobe) and the ball stud is then turned down a prescribed amount which pushes the lifter plunger downward clear of the plunger retainer. The plunger spring then presses the lifter body down against the camshaft and presses the plunger and seat up against the push rod with a ten pound load, which is enough to take up all lash clearances between parts in the valve linkage without affecting positive seating of the valve. The first few cycles of operation after the engine is started forces out all air and completely fills the plunger and lower chamber of each lifter with oil, which is supplied through the push rod as described in paragraph 2-6.

At the start of a cycle of valve operation the lifter body rests on the camshaft base circle, the plunger spring holds all lash clearances out of the valve linkage, and the check ball rests on its retainer so that the plunger feed hole is open to permit passage of oil between the plunger and lower chamber.

As the rotating camshaft starts raising the valve lifter body, oil in the lower chamber begins to flow through the open plunger feed hole but the flow immediately seats the check ball against the plunger to prevent appreciable loss of oil from the lower chamber. The lifting force against the body is then transmitted through the entrapped oil to the check ball and plunger so that the plunger and push rod seat move upward with the body to operate the linkage which opens the engine valve.

As the camshaft rotates further to close the engine valve the valve spring forces the linkage and lifter to follow the cam down. When the engine valve seats, the linkage parts and lifter plunger stop but the plunger spring forces the body to follow the cam downward .002″ to .003″ until it again rests on the camshaft base circle.

Oil pressure against the check ball ceases when the plunger stops, the check ball drops down against its retainer, and the plunger feed hole is again opened to permit passage of oil between plunger and lower chamber.

During the valve opening and closing operation a very slight amount of oil escapes through the clearance between plunger and body and returns to the crankcase. This slight loss of oil (called “leakdown”) is beneficial in providing a gradual change of oil in the lifter, since fresh oil enters the lower chamber when the feed is opened at the end of each cycle of operation.

It should be noted that during each cycle of operation the vertical movement between the body and plunger is only .002″ to .003″ but the check ball moves through its full travel of .004″ to .008″. Full opening of the plunger feed hole at the end of each cycle not only permits replacement of oil lost from the lower chamber, as previously described, but also permits control of the volume of oil in lower chamber to compensate for expansion and contraction of the valve linkage parts due to changes in engine temperature.

When engine temperature increases and the valve linkage parts expand, the plunger must move to a slightly lower position in the lifter body to assure full closing of the engine valve. When engine temperature decreases and the linkage parts contract, the plunger must move to a slightly higher position in body to prevent lash clearances in the valve linkage. In either case, the capacity of the lower chamber changes and the volume of oil present is automatically controlled by passage of oil through the open plunger feed hole.

2-6 1952 BUICK ENGINE LUBRICATION SYSTEM

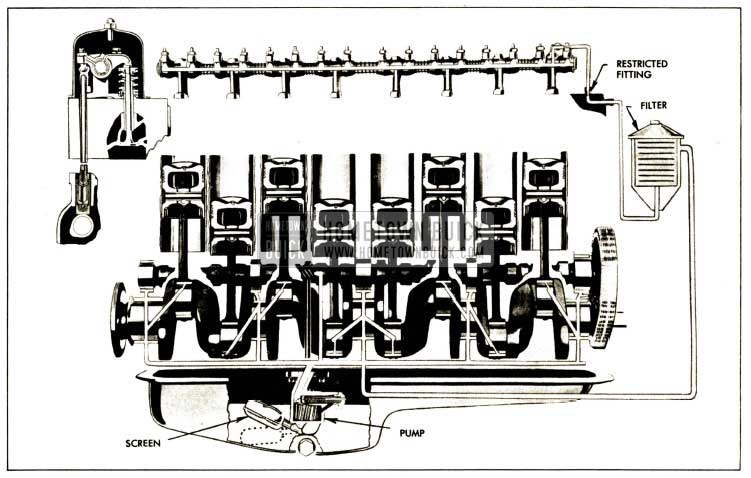

The 1952 Buick engine lubrication system is of the force-feed type in which oil is supplied under full pressure to crankshaft, connecting rod, and camshaft bearings, and is supplied under controlled volume to the rocker arm bearings, push rods, and valve lifters. All other moving parts are lubricated by gravity flow or splash. See figure 2-7.

1952 Buick Engine Lubrication System

1952 Buick Oil Supply. The supply of oil is carried in the lower crankcase, which is filled through the opening in the rocker arm cover. The filler opening is covered by a combination filler and ventilating cap which contains filtering material to exclude dust. A removable oil gauge rod on right side of crankcase is provided for checking oil level.

1952 Buick Oil Pump. Oil is picked up from the lower crankcase and circulated by a pump which consists of two helical gears inclosed in the pump body and retained by the pump cover. The oil pump is driven by the distributor shaft which is driven from the camshaft through spiral gears. The oil pump body contains a nonadjustable spring loaded pressure valve, which regulates the oil pressure to 35 pounds at 35 MPH under normal operation.

1952 Buick Oil Pump Screen. The oil pump inlet is equipped with a floating screen which is hinged so that it follows the oil level under all conditions, thus drawing clean oil from near the top above any sediment which might collect at bottom of crankcase. See figure 2-7. Should the oil pump screen become clogged due to abnormally thick oil, sludge, or other cause, suction of the pump will cause the screen to collapse at its center and open a valve that will permit oil to be drawn into the pump.

1952 Buick Main Oil Gallery. Oil under regulated pressure leaves the oil pump through a drilled passage in pump body, which connects to the main oil gallery in right side of crankcase. The main oil gallery runs the full length of crankcase to distribute oil through branch passages to all parts of the engine. See figure 2-7.

1952 Buick Crankshaft, Rods, and Pistons. Branch passages in crankcase carry oil from main oil gallery to the crankshaft bearings. Holes drilled in the crankshaft carry oil to the connecting rod bearings. See figure 2-7. Pistons and cylinder walls are lubricated by oil forced through a small hole in the lower end of each connecting rod, which registers with the hole in crankshaft once in each revolution. Piston pins are lubricated by splash.

1952 Buick Camshaft and Timing Chain. Branch passages in crankcase carry oil from main oil gallery to the camshaft bearings. The timing chain and sprockets are supplied with oil through a small passage which connects the main oil gallery with a recess and drilled hole in the camshaft thrust plate. The hole through the thrust plate is blocked by the camshaft sprocket hub except when a slot in hub registers with the hole once in every revolution of the camshaft, at which time oil is thrown into the inside area of sprocket. Three holes in the camshaft sprocket allow oil to pass to the timing chain. See figure 2-7.

1952 Buick Distributor and Pump Drive Gears. The distributor and oil pump drive gears are given positive lubrication by means of an oil passage in the crankcase running from the main oil gallery to a point in the distributor housing from which oil flows over the gears.

1952 Buick Oil Filter. All oil supplied to the overhead valve mechanism is passed through an AC oil filter which is connected by pipes to the main oil gallery and to a drilled passage in the cylinder head. The oil filter contains a folded paper low-restriction filtering element and a valve which will open at 7-9 pounds pressure to bypass oil to the outlet in case the filter element becomes plugged or otherwise inoperative.

1952 Buick Rocker Arms, Valves, and Push Rods. A short pipe under the rocker arm cover connects the drilled passage in cylinder head to the top of No. 1 rocker arm shaft bracket, through which oil is fed into the hollow rocker arm shaft. The upper pipe fitting in cylinder head has a restricted opening to control the volume of oil supplied to the rocker arm shaft. Holes in the shaft feed oil to each rocker arm bearing.

A small hole in each rocker arm feeds a slight amount of oil to the contact point between the arm and the valve stem. Another passage conducts oil to the ball stud, where it connects with a groove and oil holes in stud through which oil is fed to the push rod.

On engines equipped with hydraulic valve lifters, the push rod ends have drilled holes which permit oil to flow down through the rods into the valve lifters. The push rod upper end is counterbored to form a shroud around a bleed hole drilled in the side of push rod tube. The bleed hole permits air and surplus oil to escape from the push rod, thus eliminating air locking and preventing excessive buildup of oil pressure which would result in an oversupply of oil to the valve stem. The tubular push rod serves as a reservoir to maintain a head of oil above the valve lifter.

On Series 40 engines using plain sleeve valve lifters the push rod upper ends are not drilled, therefore oil does not enter push rods. The rod end socket is deep to form a shroud that prevents oil from spraying over valve stems. These rod ends are copper finished for identification. To reduce rocker arm shaft oil pressure, the oil inlet pipe is reduced in size to fit loosely in No. 1 bracket oil hole and thus permit oil to bleed out at this point. A baffle is located above the loose joint to direct surplus oil downward and away from valve stems.

2-7 1952 BUICK CRANKCASE VENTILATION SYSTEM

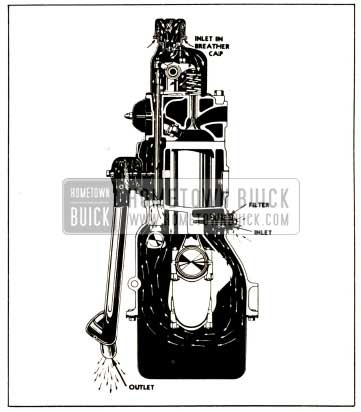

A crankcase ventilator inlet, containing a gauze filter element, and an outlet suction pipe are used to provide crankcase ventilation. Ventilation of the crankcase is accomplished by the vacuum created by the outlet pipe.

The outlet pipe is connected to the push rod cover, and extends rearward at a low level on right side of engine. Suction created by air passing the open end of the outlet pipe, when car is moving forward, causes air to be drawn into the rocker arm cover through a ventilating type oil filler cap which contains a gauze filtering element. The ventilating streams of air are drawn out of crankcase and rocker arm cover through the push rod compartment and outlet pipe. See figure 2-8.

1952 Buick Crankcase Ventilation-Section View

The air passing through the crankcase, push rod compartment, and rocker arm cover picks up fuel and water vapors and removes them from the engine. The ventilating system does not remove all fuel dilution in cold weather as a small amount is advantageous in low temperature operation. It does, however, prevent an accumulation of more than 20 % fuel dilution and removes all water under average driving conditions.

2-8 1952 BUICK ENGINE COOLING SYSTEM

The 1952 Buick engine water cooling system is the pressure type, with thermostatic water temperature control and water pump circulation. A fan located behind the radiator provides air circulation.

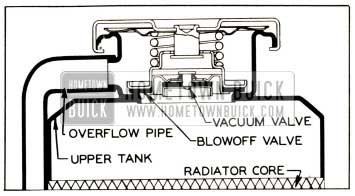

The cooling system is sealed by a pressure type radiator filler cap which causes the system to operate at higher than atmospheric pressure. The higher pressure raises the boiling point of coolant and increases the cooling efficiency of the radiator. The seven pound pressure cap used on all series permits a possible increase of approximately 20°F in boiling point of coolant.

The pressure type radiator filler cap contains a blow off or pressure valve and a vacuum or atmospheric valve. See figure 2-9.

1952 Buick Pressure Type Radiator Cap Installation

The pressure valve is held against its seat by a spring of predetermined strength which protects the radiator by relieving the pressure if an extreme case of internal pressure should exceed that for which the cooling system is designed. The vacuum valve is held against its seat by a light spring which permits opening of the valve to relieve vacuum created in the system when it cools off and which otherwise might cause the radiator to collapse.

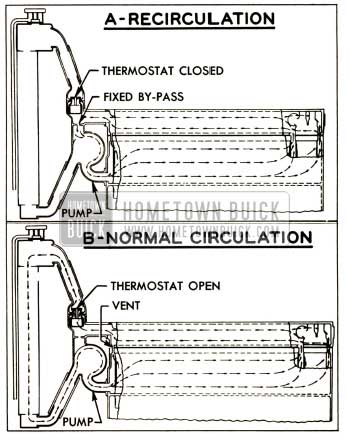

The thermostatically operated by-pass type of water temperature control permits the engine to reach its normal operating temperature quickly, by causing the water pump to circulate coolant through the engine, but not through the radiator during the warm-up period. This is accomplished by a thermostat valve located in the cylinder head water outlet, and a fixed by-pass passage located between the water outlet and the water pump inlet. See figure 2-10.

1952 Buick Cooling System Circulation

When the coolant is below normal operating temperature the thermostat valve closes and blocks circulation through the radiator. The water pump pressure forces the coolant through the by-pass passages to recirculate through the cylinder block and head. When the coolant in cylinder block and head reaches the proper temperature the thermostat valve starts to open and the circulation proceeds through the radiator in the normal way. At normal operating temperatures the thermostat is fully open.

See figure 2-10.

Water entering the cylinder block water jacket from the pump moves to the rear end of the block before flowing upward into the cylinder head water jacket and thence forward to the radiator. This path of circulation provides maximum and uniform flow of coolant over all water jacketed surfaces.

A small vent passage is located forward of number one cylinder to permit any steam forming in the cylinder block water jacket to escape into the cylinder head water jacket. See figure 2-10, view B.

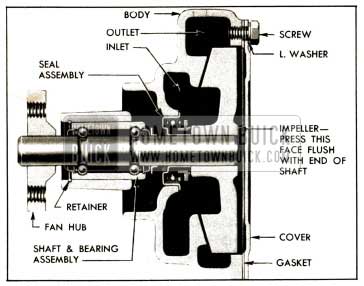

The coolant is circulated by a heavy duty centrifugal water pump mounted on the front end of the cylinder crankcase. The fan and pulley are mounted on the outer end of the pump shaft so that the pump and fan are driven by a belt from a pulley on the crankshaft. The pump shaft is incorporated in a double-row ball bearing which is sealed at both ends to exclude dirt and water and is lubricated during manufacture so that no further lubrication is required. The pump is sealed against leakage by a packless non-adjustable seal assembly mounted in the pump body in position to bear against the hub of impeller. See figure 2-11.

1952 Buick Sectional View of Water Pump

The seal assembly is composed of a brass sleeve, a helical spring, a rubber bellows, and a carbon washer. The brass sleeve is pressed into the hub of pump body. The spring presses the flanged ends of the rubber bellows against the sleeve and the carbon washer, and also presses the carbon washer against the hub of impeller to seal against passage of water. See figure 2-11. Two ridges pressed in the brass sleeve engage notches in the carbon washer to prevent the washer from turning with the impeller.

All series are equipped with Harrison V-type cellular radiator cores having copper water passages and copper cooling fins. Radiator thickness, frontal area, and cooling system capacity are given in paragraph 2-2 (g).

A thermo-gauge to indicate temperature of coolant is mounted on instrument panel. The gauge assembly includes a capillary tube with a bulb which attaches to the cylinder head so as to extend into the water jacket.

Leave A Comment

You must be logged in to post a comment.