NEW REAR AXLE PLUG, COVER

ALL SERIES

Rear axle filler plug with gasket has been OK’ed for production after jobs early in 1952. This plug which is ordered in the gasket plug kit (Gr. 5.400,No. 1390882) has a straight -14 NPSM pipe thread and shoulder and is used with leather gasket 1346117. The plug may be used in existing axle covers having a 1/2 Dryseal thread. New covers will be tapped with the straight thread hole and the torque specification for the plug in this hole is the same as at present, 20 – 30 lb. ft. When a new type plug is used in an old cover, the plug will be tight until the hole is expanded by the plug threads at assembly. In this case, tighten the plug until the gasket is securely compressed, using a lubricant (axle oil) on plug threads. This is necessary in the first insertion of the new plug, due to the excessively tight fit of old tapered threads in the cover.

REAR AXLE

AXLE RATIOS

All 1952 Series 70 models with the exception of the Model 79R Estate Wagon will have a 3.6-1 rear axle ratio as standard factory equipment. An optional 3.9-1 ratio will be factory installed on order except on Model 79R which has a 3.9-1 standard ratio with no option.

Series 40-50 axle ratios are unchanged from 1951. (Refer to Group 5, Section 5-A (c) of the 1951 Shop manual).

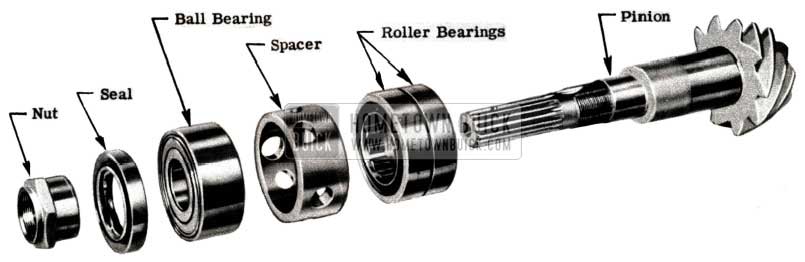

PINION BEARING OIL SEAL

All 1952 models will have the pinion bearing oil seal (Figure 30), which was formerly offered as a service item, as standard equipment.

1952 Buick Rear Axle Assembly

Installation instructions will be found in the 1952 Buick Shop Manual. It is not, however, necessary to use the fitting procedure outlined in this bulletin because the carrier is bored to correct size.

The pinion bearing seal will prevent oil seepage from the rear axle into the torque tube or propeller shaft and, in the case of a defective spline seal, into the transmission.

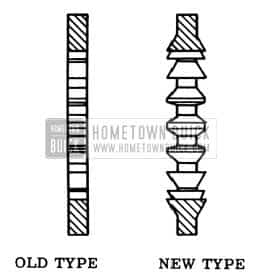

PROPELLER SHAFT SPLINE SEAL

The rubber portion of the spline seal (Figure 31) has been redesigned to provide wedge shaped internal teeth.

1952 Buick Rear Axle Propeller Shaft Spline Seal

This design will provide better conformance with mating parts, and a change in material specification provides considerably better resistance to the effects of heat and oil.

REAR AXLE FILLER PLUG

1952 – ALL SERIES

Reports indicate that some rear axle filler plugs have broken off at the vent hole when tightened. This condition is usually caused by excessive tightening of the filler plug since this plug will resist torques in excess of 50 ft. lbs. Increasing the thickness of the plug wall to compensate for the slight weakness caused by the vent hole is not desirable.

In cases where the plug has broken, the gasket behind the filler plug was found completely flattened due to excessive torque. Tests have proven that the filler plug, with gasket, will seal properly if torqued to 20-30 ft. lbs. Therefore, to eliminate unnecessary over torqueing of the filler plug, it is recommended that a torque wrench be used when installing the filler plug in the axle cover until the men servicing the rear axle become accustomed to the proper degree of tightness.

AXLE HOUSING COVER

1952 ALL SERIES

In the near future, the rear axle housing cover will be replaced in production by the cover used during 1951. This cover has a higher filler plug hole location which increases axle oil capacity approximately 1 pint.

The increased quantity of oil appreciably reduces axle operating temperatures at high speeds and also assists in reducing early gear and bearing wear. The additional oil capacity insures a constant supply of oil in the bottom of the housing when taking high speed turns.

Whenever axle trouble is experienced with 1952 cars and the job is torn down for service, we recommend installation of the 1951 type axle housing cover and plug assembly, Group 5.398, Part No. 1390887.

PROPELLER SHAFT INTALLATION

ALL DYNAFLOW MODELS

The Inspection Department reports that several defective ring and pinion gears returned from the field show clear indication of operation in rear axle lubricant contaminated with Dynaflow oil. In a number of these cases, further investigation revealed the propeller shaft assembly had been previously removed and replaced without separating the torque tube at the torque ball and moving the third member assembly back.

When the propeller shaft is removed and replaced with the third member in place, the spring loaded propeller shaft spline seal falls -out of place and cannot be repositioned to prevent escapage of Dynaflow oil into the rear axle. This point is emphasized in the note on page 242, paragraph 5-10 of the 1952 Shop Manual.

Service Managers should inform mechanic personnel that the flat operation covering R and R propeller shaft includes time necessary to correctly perform the operation as outlined in the Shop Manual.

PROP SHAFT AND PINION PRESS

We have been advised that difficulty is experienced when using the Kent-Moore J-1292-B propeller shaft and pinion press on models equipped with a pinion bearing oil seal. Due to insufficient clearance, some dealers are pulling the shaft from the pinion without using the “C” washer (J-1292-38). This usually results in oil seal and bearing damage. The “C” washer can be made usable by grinding stock from the flat side of the washer so that thickness is reduced from 5/8″ to 5/16”. When this modification is made the press can be used in the intended manner (with pressure applied against the lock nut) and any undamaged pinion bearing oil seals can be reinstalled.

All J-1292-B presses shipped in the future will include a 5/16″ “C” washer (J-1292-38) in addition to the regular 5/8″ washer.

Leave A Comment

You must be logged in to post a comment.