BRAKE DRUM SEALING TAPE

Further investigation and testing by the Engineering Department has revealed a material, for sealing between the brake drum and backing plate, that is considerably more durable than the felt material formerly recommended. The new material is Tadpole Gasketing Tape, Style No. 123, Size #1, consisting of a center core of soft asbestos wick with an asbestos cloth cover that is extended to form a flange. Tadpole Tape can be obtained in standard 50 foot rolls from the Johns-Manville Corporation. Their district offices are located as follows:

816 West 5th St.

Los Angeles 13, Calif.

116 New Montgomery St.

San Francisco 5, Calif.

1755 Glenarm Pl.

Denver 2, Colorado

101 Marietta St.

Atlanta 3, Georgia

Merchandise Mart Plaza

Chicago 54, Illinois

45 Prospect Ave.N.W.

Cleveland 15, Ohio

100 Newbury St.

Boston 16, Mass.

Central Pkwy. at Walnut St.

Cincinnati 2, Ohio

Grand Blvd. at Second St.

Detroit 2, Michigan

1000 Market St.

St. Louis 1, Mo.

270 Madison Ave.

New York 16, N.Y.

717 Liberty Ave.

Pittsburgh, Pa.

3115 Blodgett St.

Houston 4, Texas

777 Thomas St.

Seattle 9, Wash.

The following procedure should be used when installing Tadpole Gasketing Tape.

- Thoroughly remove all dirt and grease from the outer rim of the backing plate.

- Trim the flange of the tape to an approximate 5/8″ width, using tin snips or heavy shears.

- Coat the flange of the backing plate and the tape with a good quality rubber cement such as 3-M # 711. Allow the cement to dry.

- Apply the tape to the backing plate with the bulb portion of tape placed in the gap between the edge of the plate and the brake drum rib. The bulb should contact the drum rib with a light pressure in order to effect a good seal.

(See Figure 26) Avoid excessive rubbing pressure which will cause the drum to overheat in operation.

1951 Buick Brake Assembly

- Leave a 1/4″ gap between the tape ends at the bottom of the backing plate to allow normal brake wear dust to escape.

- Form the tape down on the curved portion of the backing plate with hand pressure.

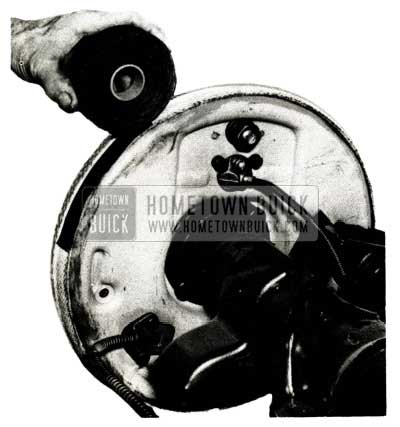

- Use ordinary friction tape (Figure 27) to hold the gasketing tape in place until the cement is thoroughly set.

1951 Buick Brake Friction Type

When this material is installed it is definitely “tailored” to the parts used in making the installation. Any change, such as replacing a drum, axle shaft, etc., which changes the gap between the drum and backing plate, necessitates replacement of the tape.

BRAKE SQUEAK CORRECTION

1951 SERIES 70

Supplements Sec. 8-B, Par. 8-7 (h), 1951 SM

An appreciable reduction in 1951 Series 70 brake squeak can be made by installing dampening springs in the drum grooves between the rib and the edge of the backing plate. These springs are available through regular parts channels under Group 5.810, Part No. 1345469.

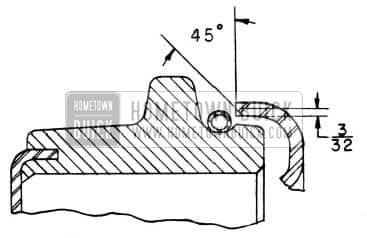

When making installation all drums should be carefully checked for an interference condition between the springs and backing plates. If a light interference exists, a 45° chamfer should be ground on backing plate as shown in Figure 28.

1951 Buick Brake Squeak Correction

If interference is more severe, it will be necessary to rework the drums as shown in Figure 29.

1951 Buick Brake Drum Rework

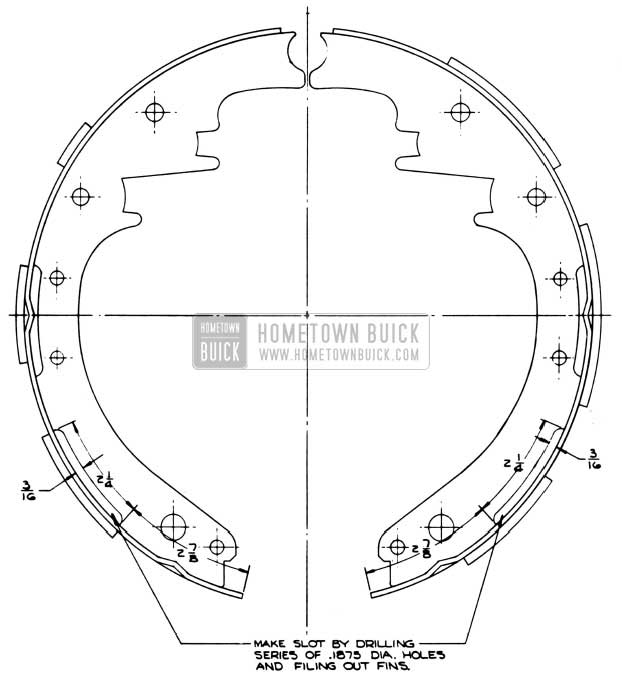

In cases where installation of dampening springs does not satisfactorily eliminate squeak, it will be necessary to provide additional slots between the brake shoe web and rim. The size and location of required slots is shown in Figure 30.

1951 Buick Brake Show Web and Ring

The slots should be made by drilling a series of overlapping 3/16″ holes and then filing out the remaining fins. The webs must be solidly supported when center-punching the holes or web distortion will likely occur. For the same reason, no attempt should be made to cut the slots with a chisel.

Leave A Comment

You must be logged in to post a comment.