UNEVEN TIRE WEAR

1948 THRU 1951 ALL SERIES

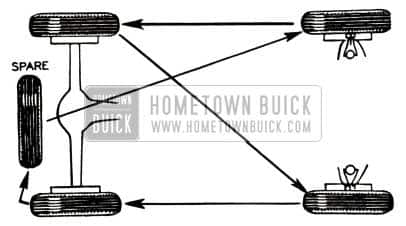

Numerous reports from the field concerning uneven tire wear and shimmy after driving relatively low mileages indicate that owners are not following our instructions regarding the regular crisscrossing of their tires at 2000 to 4000 mile intervals. The majority of complaints seem to be from relatively hard drivers – indicating that a definite wear pattern on the tread is established sooner than would normally be expected. If tires have been driven too long in a given wheel position, criss-crossing will not help cure the shimmy. The object of criss-crossing is to even up an irregular wear condition before it has gone too far. Naturally then, hard drivers will have to crisscross their tires more frequently than the 4000 mile interval specified in our Owners Guide and Shop Manuals.

Most of you are aware of the fact that in practically all cases where this shimmy condition is encountered it can be eliminated by installing new tires. This is true, of course, providing there isn’t something mechanically wrong with the front suspension or steering mechanism, such as improper wheel alignment, loose tie rod ends, or an improperly lashed steering gear.

We have been emphasizing regular tire crisscrossing ever since we started using the extra low pressure type tires. Its importance cannot be stressed too much to your owners.

We are repeating, in Figure 25, the criss-crossing diagram we recommend in all of our service literature and direct mail.

1951 Buick Uneven Tire Wear

CHASSIS SPRING TRIM HEIGHTS

1951 AND PAST MODELS

Under certain operating conditions it is advisable to provide greater front and rear spring height to prevent excessive “bottoming”. Many owners object to installation of domestic high or overload springs from a standpoint of appearance and riding ease. The most satisfactory solution in these cases is to shim the springs rather than to make indiscriminate spring replacement which, in a large number of cases, produces other conditions that are more objectionable than the original cause for complaint.

Increased front end trim height can be obtained by installing two or three 1/8” steel shims (Group 7.425 Part No. 1310413) between the insulator and the frame. Due to the geometry of the front suspension, this will provide an additional lift of 3/8″ with 2 shims and 5/8″ with 3 shims. When making front spring shim installation, follow instructions given in Section 6-C, Paragraph 6-18 of the 1951 Shop Manual. Following the shim installation it is essential to check toe-in, caster and camber and adjust as necessary.

The 3/16″ rear spring insulator (Group 7.545, Part No. 1305014) is very satisfactory for use as a rear shim. As many as three insulators can be used in •addition to the one already in place in the upper spring seat. When a total of four insulators are used, it is advisable to install two at the top and two at the bottom in order to utilize the original clamp bolts and insure proper spring stability. When making this installation refer to instructions given in Section 6-C, Paragraph 6-21 of the 1951 Shop Manual.

These procedures can also be used to restore trim heights, particularly front end, on past models.

Leave A Comment

You must be logged in to post a comment.