SECTION 4-B 1956 BUICK SYNCHROMESH TRANSMISSION AND UNIVERSAL JOINT

NOTE: 1956 Buick Synchromesh Transmission is standard and Dynaflow transmission is optional on Series 40. Dynaflow is standard and Synchromesh is not available on Series 50-60-70.

4-7 1956 BUICK SYNCHROMESH TRANSMISSION AND UNIVERSAL JOINT SPECIFICATIONS

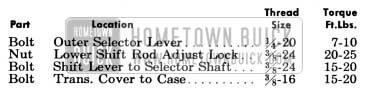

Tightening Specifications

1956 Buick Synchromesh Transmission Tightening Specifications

1956 Buick Synchromesh Transmission Tightening Specification

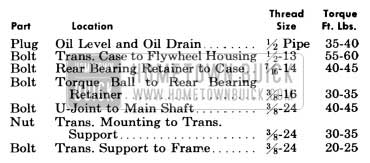

1956 Buick Synchromesh Transmission Specifications

NOTE: Where dimensions and limits for fit of parts are given in these specifications they apply to new parts only. Where limits are given, “T” means tight and “L” means loose.

1956 Buick Synchromesh Transmission Specifications

Universal Joint and Torque Ball

1956 Buick Universal Joint and Torque Ball Specifications

Speedometer Gears

1956 Buick Synchromesh Transmission Speedometer Gears

4-8 1956 BUICK SYNCHROMESH TRANSMISSION DESCRIPTION

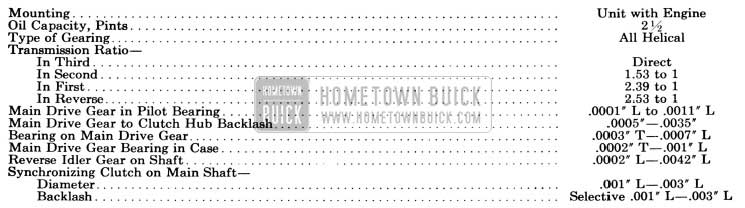

The 1956 Buick Synchromesh Transmission is solidly bolted to the rear face of flywheel upper housing, with a heavy paper gasket between, to form a unit assembly with the engine. The transmission main drive gear extends through the clutch driven plate into a single-row-ball pilot bearing seated in the rear end of engine crankshaft. The outer race of main drive gear bearing projects from transmission case to seat in a counterbore in flywheel housing, thus serving as a pilot to center the transmission with engine crankshaft.

1956 Buick Synchromesh Transmission Gears and Shafts

The transmission main drive gear is supported by a ball bearing seated in front wall of transmission case. The ball bearing, which is shielded on rearward side, is pressed against a shoulder on main drive gear and held in place by an oil slinger, washer, and retainer (snap ring). The outer race of bearing is grooved for a snap ring which fits between 1956 Buick Synchromesh Transmission case and flywheel housing to hold bearing and main drive gear in place. See figure 4-7.

1956 Buick Synchromesh Transmission

The front end of transmission main shaft is piloted in the bored rear end of main drive gear by a bearing consisting of 14 small rollers which are retained in drive gear by a washer and snap ring. The main shaft is also supported by the transmission rear bearing which seats in the rear wall of transmission case. The outer race of rear bearing is grooved for a snap ring which fits between transmission case and the rear bearing retainer. The inner race of bearing is retained between a shoulder on main shaft and a snap ring seated in a groove in shaft. A bushing in rear bearing retainer supports the main shaft just forward of the universal joint.

The transmission counter gear is supported by two roller bearings on a shaft which is held stationary in 1956 Buick Synchromesh Transmission case by a grooved pin lock driven into holes in case and rear end of shaft. A tubular spacer and two thrust washers are located around the shaft between the roller bearings and a retaining washer is located at outer end of each bearing to hold rollers in position. End thrust is taken by a bronze thrust washer at each end of counter gear, with rear washer backed by a steel thrust washer. A hole in hub of gear permits lubricant to reach bearings and thrust washers. See figure 4-7.

The reverse idler gear is provided with two bronze bushings and is supported on a shaft which is held stationary by a grooved pin lock driven into holes in transmission case and front end of shaft. End thrust is taken by a bronze thrust washer at each end of idler gear. A hole in hub of gear permits lubricant to reach bushings and thrust washers.

The second speed gear is provided with a bronze bushing and is mounted on the main shaft in position to mesh with the counter gear. It is held in position between a shoulder on main shaft and a thrust washer retained by a snap ring. The gear is free to rotate on the main shaft except when engaged by the gear synchronizing clutch during second speed operation.

The first and reverse sliding gear is splined to the main shaft, to rear of second speed gear, so that it can be moved forward to engage the counter gear for first speed or rearward to engage reverse idler for reverse. Its forward movement is limited by a snap ring retainer installed in a groove in main shaft. See figure 4-7.

1956 Buick Synchromesh Transmission Gear Shift and Synchronization

The gear synchronizing clutch and the first and reverse sliding gear are actuated by the shift mechanism. The gear shift mechanism is described in paragraph 4-8.

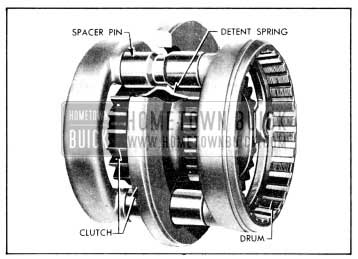

The gear synchronizing clutch is splined to the main shaft to transmit drive when clutch is engaged with either the main drive gear (third speed) or the second speed gear. The clutch assembly includes synchronizing drums and detent springs which act to synchronize the speed of the clutch with the gear it engages during a shift into second or third speed. The drums are joined together by three spacer pins which are notched to engage three detent springs which support the synchronizing parts on the clutch. See figure 4-8.

1956 Buick Gear Synchronizing Clutch

As the clutch moves toward the gear, the detent springs press the drum into contact with the gear, after which the detent springs compress and disengage notches in the spacer pins to permit the clutch to engage the gear quietly and easily.

Speedometer Gears

The speedometer driving worm gear is pressed on the transmission main shaft where it is located by a stop ring. See figure 4-7. The same worm is used in all series for all rear axle ratios. In changing axle ratios it is only necessary to change the driven gear.

The speedometer driven gear is furnished only as an assembly consisting of sleeve, shaft, retaining washer and gear. The driven gear sleeve is threaded into the transmission rear bearing retainer and the speedometer cable is attached to the sleeve by a threaded sleeve on cable casing. The speedometer gears and driven gear shaft are lubricated from the 1956 Buick Synchromesh Transmission.

Universal Joint and Torque Ball

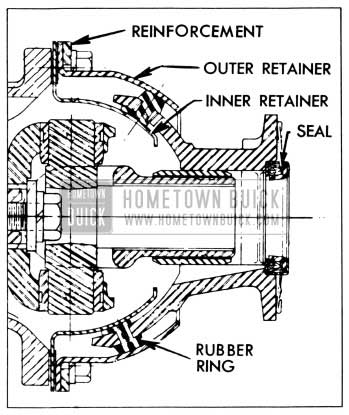

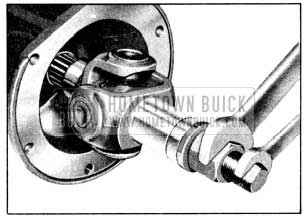

The universal joint is splined to the rear end of transmission main shaft and retained by a heavy steel washer and bolt. It is entirely enclosed by the transmission rear bearing retainer and by the torque ball and retainers which are attached to rear end of the bearing retainer.

The universal joint yokes are provided with hardened and ground steel bushings, held by retainer rings, which provide bearings for the hardened and ground pins of the universal joint cross. The rear yoke is splined internally to engage the propeller shaft, and is ground externally to provide a bearing in a bronze bushing in the torque ball. See figure 4-7.

The torque ball is supported between an inner and outer retainer which are centrally located and bolted to the transmission rear bearing retainer. The torque ball has two bonded rubber compression rings which act as a double rubber cushion and seal between the ball and the inner and outer retainers.

The universal joint, torque ball, and speedometer drive gears are automatically lubricated from the 1956 Buick Synchromesh Transmission. A breather or air vent is installed in upper side of the rear bearing retainer to prevent a build up of pressure, due to heat, that would force transmission lubricant out past gaskets and oil seals. See figure 4-7.

4-9 1956 BUICK SYNCHROMESH TRANSMISSION SHIFT CONTROL MECHANISM

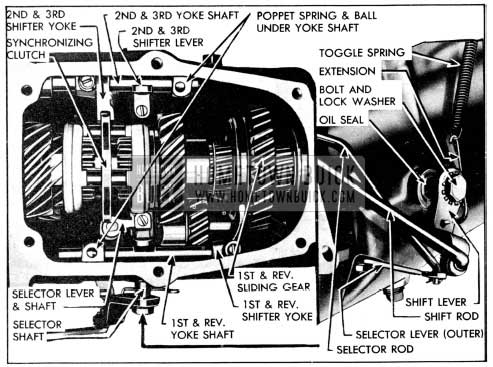

The first and reverse sliding gear is moved forward or rearward from the neutral position by a shifter yoke mounted on a shaft supported in left side of transmission case. The gear synchronizing clutch is actuated by a yoke and shaft on right side of case. Each shifter yoke shaft is notched for engagement by one of two shifter levers mounted on a selector shaft which is supported in 1956 Buick Synchromesh Transmission case at a right angle to yoke shaft. The levers are located on selector shaft so that only one lever at a time can engage its yoke shaft. See figure 4-9.

1956 Buick Shift Mechanism in Transmission

Engagement of a shifter lever with its yoke shaft, to select a gear shift, is obtained by moving selector shaft to right or left as required. This transverse movement of selector shaft is made by a selector lever and shaft which engages a notch in first and reverse shifter yoke. The selector lever shaft extends through transmission case and has a lever on its outer end which is actuated by a selector rod connected to the selector control mechanism in steering column.

Forward or rearward movement of the selected shifter yoke shaft, to complete the gear shift, is obtained by rotating the selector shaft. This movement is made by a shift lever mounted on outer left end of shaft and actuated by a shift rod connected to the gear shift control mechanism in steering column. A toggle spring and extension attached to shift lever aids in moving the sliding parts. See figure 4-9. A spring loaded poppet ball, housed in a recess in transmission case under each yoke shaft, engages one of three recesses in shaft to hold the shaft in desired position.

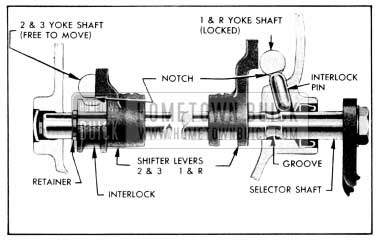

An interlock arrangement permits movement of one shifter yoke and shaft only when the opposite yoke shaft is locked in neutral position. The selector shaft pushes an interlock pin up into a notch in the first and reverse shifter yoke shaft to lock it when selector shaft moves to the right. When the selector shaft moves to the left, the interlock pin drops into a groove in selector shaft, thereby unlocking the yoke shaft. A grooved collar mounted on right end of selector shaft and a notch in the second and third shifter yoke shaft provide the locking device for that yoke shaft. See figure 4-10.

1956 Buick Transmission Interlock

4-10 1956 BUICK SYNCHROMESH TRANSMISSION TROUBLE DIAGNOSIS

Hard Shifting and Block-out

Hard shifting may be caused either by conditions in shift control mechanism in steering column or by conditions in 1956 Buick Synchromesh Transmission assembly. Disconnect shift rod trunnion at control shaft lever to determine which unit is at fault.

Conditions in 1956 Buick Synchromesh Transmission assembly which may cause hard shifting are: (1) If there is excessive resistance at start of shift, shifter yoke shaft poppet spring probably too stiff. (2) Shifter yoke shaft may be bent.

Low and Reverse Gear Clash

1956 Buick Synchromesh Transmission gears can be made to clash by shifting into low or reverse gear too quickly after clutch pedal is depressed, even though clutch is in perfect working order. This is because inertia of clutch driven plate causes the plate to spin until it is stopped by friction of transmission and transmission lubricant. With warm transmission lubricant and low friction transmission bearings, a reasonable amount of spin is to be expected. The spin does not occur when shifting quickly into second or high gear because the synchronizing unit stops the driven plate.

To eliminate gear clash, sufficient time MUST be allowed before shifting into low after pedal is depressed or else starts must be made in second gear. There is no objection to making starts in second gear on level ground since the clutch slippage under ordinary driving conditions is not sufficient to produce enough heat to damage driven plate facings.

If gear clash continues after allowing proper time for clutch driven plate to stop, check clutch pedal lash and adjust to specified limits. See paragraph 4-4. In exceptional cases of driven plate spinning, clutch pedal lash should be maintained at 1/2″- Make sure that idle speed of engine when hot is 450 RPM. A faster idle aggravates driven plate spinning.

Conditions within the 1956 Buick Synchromesh Transmission which may cause gear clash are: (1) Faulty synchronizing drums or cone surfaces; (2) Excessive main shaft end play; (3) Weak or broken detent springs in gear synchronizing clutch; ( 4) Gear clash also may be caused by a dragging clutch plate.

Noise in Neutral

With car standing, engine running, and 1956 Buick Synchromesh Transmission in neutral, the transmission parts in operation are: main drive gear and bearing, counter gear and bearings, reverse idler gear, second speed gear, main shaft pilot bearing. Disengaging clutch will stop movement of all these parts. By disengaging and engaging clutch it can be determined whether noise originates in these transmission parts and whether the noise is normal. Noise in neutral in the form of a constant regular click is usually caused by a nicked gear or bearing.

Gear Noise

Some gear noise is to be expected in all except third speed. Comparison with another car is the only means of determining whether or not gear noise is excessive. Before removing transmission for correction of gear noise determine by test which gears are noisy under load, so that these can be thoroughly inspected when removed.

Gear Rattle During Acceleration

Improperly calibrated clutch driven plate, faulty crankshaft balancer, or scored rear axle gears may cause rattle in 1956 Buick Synchromesh Transmission in third speed, on acceleration. Rattles occurring on wide open throttle between 40 and 60 MPH are usually caused by improper clutch driven plate dampening; a new driven plate should be installed if rattles are objectionable.

Noise When Shifting out of First or Reverse

Shifting out of first or reverse very slowly will usually result in some noise just as the gears disengage. This is normal because of the gear pointing necessary for easy engagement.

Abnormal noise during normally fast shift may be caused by improper clutch release. Check clutch pedal lash and adjust. See paragraph 4-4.

Abnormal noise during normally fast shift, when clutch release is satisfactory, may be caused by damage to pointing on engaging side of teeth on counter gear, reverse idler gear or first and reverse sliding gear. Noise when disengaging both first and reverse, indicates that fault is with sliding gear only. Noise when disengaging reverse only indicates reverse idler gear at fault. Noise when disengaging first speed only indicates counter gear at fault. Tests must be made by disengaging gears while car is still in motion.

Gear Jump-out

In any case of gear jump-out, first check the adjustment of gear shift control mechanism as described in paragraph 4-11. Make certain that poppet balls have full engagement in notches in shifter yoke shaft in all speed positions and neutral. Also make certain that toggle spring extension is not distorted so that it contacts the selector shaft. If these items do not correct gear jump-out, remove 1956 Buick Synchromesh Transmission for examination of parts.

Gear jumping out of third speed may be caused by misalignment between the flywheel housing and crankshaft. See paragraph 4-14 for alignment correction procedure.

Gear jump-out in any transmission speed position may be caused by loose fit of bearings or bushings involved, weak poppet springs, loose fit of synchronizing clutch on main shaft, loose fit of sliding gear on main shaft, worn teeth on mating gears. All items should be carefully inspected.

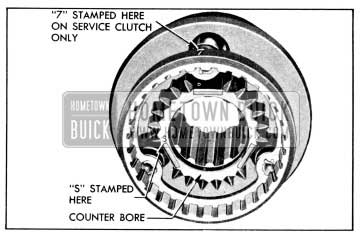

Jumping out of second speed may be caused by gear synchronizing clutch being installed with wrong end toward second speed gear. See figure 4-23.

1956 Buick Synchromesh Transmission Lubricant Loss at Torque Ball

Transmission lubricant may be lost at torque ball as a result of:

- Scored universal joint or bushing.

- Clearance of more than .006″ between universal joint and bushing in torque ball.

- Worn or damaged propeller shaft oil seal.

- Excessive run-out of front end of propeller shaft.

- Worn or damaged rubber contact rings on torque ball faces.

Scored or Broken Gear Teeth

Gear teeth will be seriously damaged and possibly broken, by failure of car operator to fully engage gears on every shift before engaging clutch and applying engine power.

Considerable damage to gears and bearings will result from running at abnormal speeds in reverse, first and second speed gears. This practice is also detrimental to the engine.

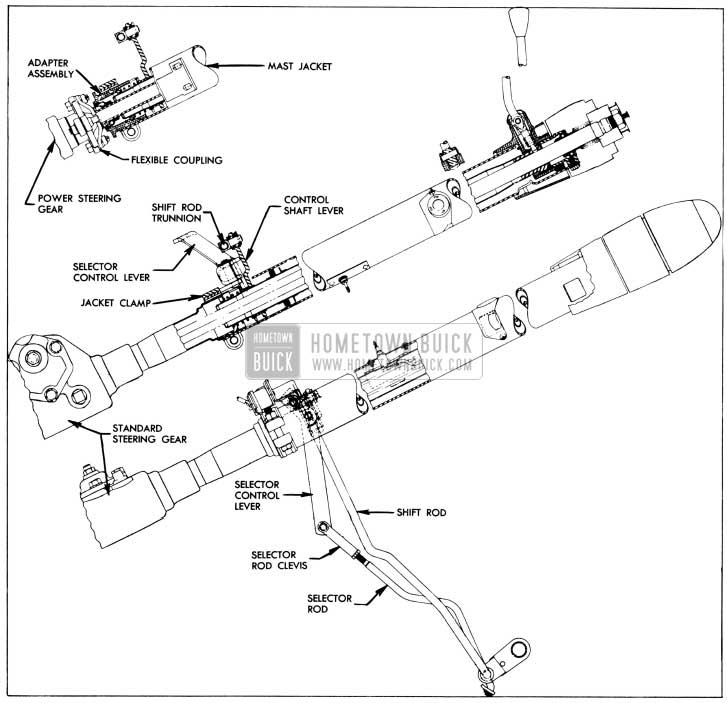

4-11 ADJUSTMENT OF 1956 BUICK SYNCHROMESH TRANSMISSION SHIFT CONTROLS

All adjustments are made with the 1956 Buick Synchromesh Transmission in neutral and in position for shifting into second or third gear.

1956 Buick Synchromesh Transmission Shift Mechanism

- Raise or lower jacket clamp assembly until selector control lever pivot pin clears control shaft lever by 5/8″. Then tighten clamp securely.

- Adjust shift rod trunnion so that lower control shaft lever is mid-way in mast jacket opening with 1956 Buick Synchromesh Transmission in neutral.

- Adjust selector rod clevis so that with selector rod held to the rear, the clevis pin will enter hole in selector control lever without moving lever.

- Shift 1956 Buick Synchromesh Transmission into each gear to check for proper shifting and to check control shaft lever

4-12 REMOVAL AND INSTALLATION OF TORQUE BALL

The torque ball has two bonded rubber contact rings on the ball faces which are compressed between steel inner and outer retainers. All motion of the ball is taken by flexing of the rubber, which forms an oil-tight seal. A reinforcement is used under the retainer bolt heads to avoid distortion of the retainers. No shim adjustment is required on bonded rubber torque ball.

- Disconnect rear axle assembly and move it back out of the way (par. 6-4,a). CAUTION: Be sure torque ball retainer bolts are loose and torque tube guide pins are installed before moving axle assembly back to avoid damaging propeller shaft seal.

- Remove retainer bolts, reinforcement, torque ball, retainers and gaskets from transmission rear bearing retainer. See figure 4-12.

1956 Buick Torque Ball Assembly

4-13 REMOVAL AND INSTALLATION OF 1956 BUICK SYNCHROMESH TRANSMISSION

Removal of 1956 Buick Synchromesh Transmission

- Disconnect rear axle assembly and move it back out of the way (par. 6-4). CAUTION: Be sure torque ball retainer bolts are loose and torque tube guide pins are installed before moving axle assembly back.

- Drain transmission lubricant. Fill with clean kerosene and run transmission in neutral for about 15 seconds. Drain cleaner.

- Disconnect speedometer cable, shift rod, and selector rod.

- Disconnect rubber thrust pad from transmission support by removing three nuts and plate, then lift out shims located between support and transmission thrust pad. Remove two bolts and plate which attach 1956 Buick Synchromesh Transmission mounting pad to the support.

- Place a suitable jack under rear of engine so that engine will be safely supported while transmission is removed.

- Raise engine and transmission just enough to relieve the load on transmission support, then remove the support from frame, noting location and number of shims present. Remove thrust pad from thrust plate.

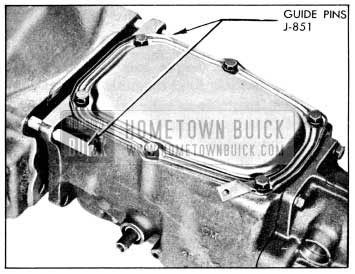

- Remove the two top transmission to flywheel housing bolts and install Guide Pins J 851 to support transmission. See figure 4-13.

1956 Buick Transmission Guide Pins J-851

Remove lower bolts, then move transmission straight back and lower to floor. CAUTION: If guide pins are not used and weight of 1956 Buick Synchromesh Transmission is allowed to rest on main drive gear in clutch driven plate hub, the driven plate will be damaged.

Installation of 1956 Buick Synchromesh Transmission

- Lightly coat the splines on end of main drive gear with Lubriplate for a distance of not more than 1″. Do not apply an excess that will push off at driven plate hub and get on driven plate facings.

- Make certain that front face of transmission case and face of flywheel housing are absolutely clean. Install Guide Pins J 851 in upper bolt holes in housing (fig. 4-13) and install a new transmission gasket. Make certain that spring washer is in place behind clutch release bearing support in housing.

- Lift 1956 Buick Synchromesh Transmission into place and fully support it until the main drive gear bearing enters flywheel housing. Clutch driven plate will be damaged if guide pins are not used and weight of 1956 Buick Synchromesh Transmission is allowed to rest on main drive gear in driven plate hub.

- Install lower transmission attaching bolts, then the upper bolts, and tighten all bolts evenly and securely. CAUTION: If a gap exists between transmission case and flywheel housing do not tighten bolts as case may be broken. Remove transmission and check position of main drive gear bearing snap ring, which may have slipped out of place during installation.

- Install rubber thrust pad on thrust plate attached to bearing retainer. Install transmission support with original shims, which should be of proper number and thickness to just fill space between support and frame.

- Lower the transmission to rest on the support and attach the mounting pad to the support with bolt plate and self-locking nuts.

- With engine and transmission resting freely and normally on mountings, install sufficient shims between the thrust pad and transmission support to fill the existing space. Insert shims from above, then install the bolt plate and three nuts which attach thrust pad to support. See figure 2-41.

- Connect speedometer cable.

- Connect lower shift rod and selector rod to their levers.

- Inject 1/2 pint of transmission lubricant into torque ball through universal joint splines. Then fill 1956 Buick Synchromesh Transmission to filler plug level with approximately 2 pints of lubricant. See paragraph 1-1 for specified lubricant.

- Install rear axle assembly (par. 6-4).

- Road test car, checking for proper selection and shifting of transmission, correct synchronization, and quiet operation of gears, bearing-s and shifter yokes. In neutral the lower control shaft lever should be midway in the mast jacket opening. It may be necessary to adjust transmission shift controls as described in paragraph 4-11.

4-14 ALIGNMENT OF FLYWHEEL UPPER HOUSING

The flywheel upper housing which joins the 1956 Buick Synchromesh Transmission to the engine crankcase is attached to the crankcase by bolts, with two straight dowels to maintain alignment.

Misalignment between the pilot hole which receives the main drive gear bearing in rear wall of housing and the pilot bearing in rear end of crankshaft may cause the 1956 Buick Synchromesh Transmission to be noisy or to slip out of high gear. To insure correct alignment in production, the pilot hole is bored in the housing after it is assembled to the cylinder crankcase. The flywheel housing furnished for service is completely machined, but it must be checked for alignment after installation.

If an existing housing is suspected of being out of alignment it may be checked after removal of the transmission and clutch assemblies. If a new housing or cylinder crankcase is being installed, alignment should be checked before the flywheel, clutch and transmission are installed. When checking alignment the engine must be in an upright position, dowel pins must be installed, and all housing bolts must be tight.

Checking Alignment of Flywheel Upper Housing

- Remove 1956 Buick Synchromesh Transmission (par. 4-13) and clutch (par. 4-5), leaving flywheel in place.

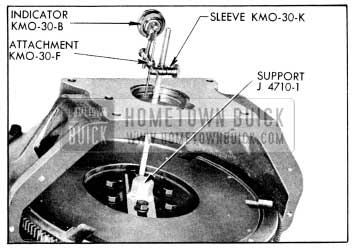

- Attach Indicator Support J 4710-1 to flywheel with two flywheel bolts. Mount Dial Indicator KMO 30-B and Hole Attachment KMO 30-F on pilot with Sleeve KMO 30-K. Adjust ball end of hole attachment to bear against side of pilot hole in flywheel housing. See figure 4-14.

1956 Buick Checking Alignment of Housing at Pilot Hole

Correction of Flywheel Upper Housing Misalignment

- Remove flywheel upper housing and dowel pins from crankcase.

- Drill out bolt holes in flywheel housing with a 1/2″ drill.

- Install flywheel housing without dowel pins, and leave bolts just loose enough to permit shifting of housing by tapping with lead hammer.

- Install dial indicator as shown in figure 4-14, and check run-out at pilot hole in housing.

- Shift housing by tapping with lead hammer as required to bring run-out at pilot hole within .002″ indicator reading. Tighten housing bolts and re-check run-out.

- Using Special Reamer J 2548-3 and Ratchet Wrench J 808-6, ream the dowel holes and install two oversize dowel pins J 808-5.

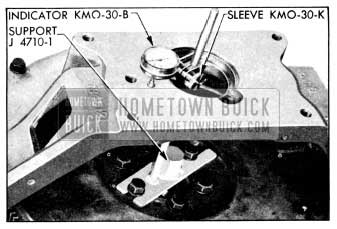

- Mount dial indicator to bear against rear face of flywheel housing at a radius of 2%”, as shown in figure 4-15.

1956 Buick Checking Run-Out of Rear Face of Housing

4-15 DISASSEMBLY, INSPECTION, ASSEMBLY OF 1956 BUICK SYNCHROMESH TRANSMISSION

Disassembly of 1956 Buick Synchromesh Transmission

- Thoroughly clean all dirt from exterior of 1956 Buick Synchromesh Transmission to avoid getting dirt into bearings when transmission is opened.

- Remove 1956 Buick Synchromesh Transmission cover and gasket, toggle spring, and spring extension.

- Remove speedometer driven gear.

- Remove torque ball assembly (par. 4-12).

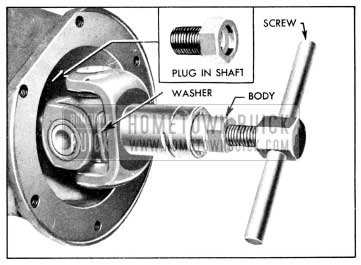

- Remove retaining bolt and washer, then pull universal joint from main shaft, using Puller J 682-A. To use puller, install the pressure plug in transmission main shaft, insert puller body in universal joint rear yoke and install “C” washer in groove in puller body on front side of yoke, then turn screw handle clockwise. See figure 4-16.

1956 Buick Removing Universal Joint with Puller J 682-A

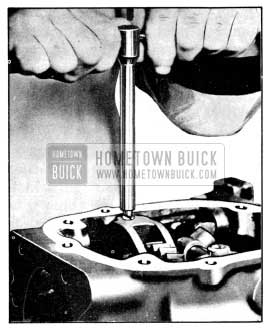

1956 Buick Removing Set Screw with Remover J 2895

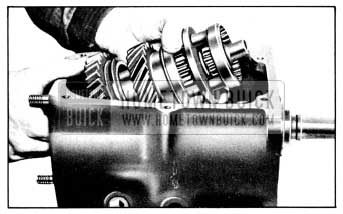

1956 Buick Removing Main Shaft Assembly

1956 Buick Removing Snap Ring from Main Shaft

Cleaning and Inspection of 1956 Buick Synchromesh Transmission Parts

Clean and inspect all ball and roller bearings as described under Bearing Service (par. 1-10). Thoroughly clean all other parts except rubber mountings in CLEAN solvent and wipe dry with CLEAN cloths. Inspect parts as follows:

- Gears and Shafts. Carefully inspect teeth and other ground surfaces of all gears for wear, scoring, pitting, chips, nicks, and burrs. Do not confuse manufacturing cutter marks with scores or pits. Conical surfaces of gears where contacted by synchronizing drums must be smooth and free of burrs. Slight scores or burrs may be honed off with a fine stone, however, if any gear is chipped or excessively worn it should be replaced.

Inspect all shafts for wear roughness on bearing surfaces. Check fit of gears on shafts upon which they are mounted. The sliding sleeve must slide freely on splined section of main shaft, but without appreciable backlash. - Synchronizing Drums. The cam surfaces of synchronizing drums must be smooth. The conical surfaces of synchronizing drums must be free of burrs or scores, and oil grooves must be clean. Never polish this surface or change the angle.

- Selector Shaft, Shifter Yokes and Shafts, Toggle Spring Extension. Check selector shaft and shifter yoke shafts on a flat surface to see whether they are bent. A bent shaft will cause hard shifting, and should be replaced. If a shifter yoke is bent or has rough contact surfaces it will cause hard shifting and noise, therefore, it should be replaced. Replace poppet springs if distorted or of doubtful strength.

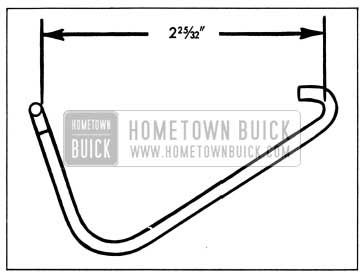

Check toggle spring extension to make sure it is not distorted. An improperly shaped extension will bear against the selector shaft and actually tend to pull transmission out of second speed. Figure 4-20 shows the correct shape for extension. A bent extension should be reshaped to dimension shown, or replaced.

1956 Buick Toggle Spring Extension

The front yoke must be a tight fit, rotatively, on main shaft to prevent “snap” when alternating car movement between forward and reverse. The rear yoke of universal joint and bushing in torque ball must be free of scores and not worn excessively; clearance between these parts should be .004″ to .006″.

Assembly of 1956 Buick Synchromesh Transmission

Assemble the 1956 Buick Synchromesh Transmission by reversing the sequence of steps given for disassembly. In addition, observe the following instructions that apply to assembly.

- Condition of Parts. Make certain that all parts are absolutely clean and that gears and synchronizing drums are free of nicks or burrs. Use all new gaskets and oil seals or packings to insure against leakage of lubricants. Use all new snap rings, and retainers of snap ring type. Snap rings, are frequently distorted during removal and are difficult to true up satisfactorily for further service.

- Observe instructions given under Bearing Service (1-9) on proper installation of ball bearings. Coat bearings with clean transmission lubricant at time of installation, to insure initial lubrication.

- Universal Joint. Use Replacer J 855 to install universal joint on main shaft. See figure 4-21.

1956 Buick Installing Universal Joint with Replacer

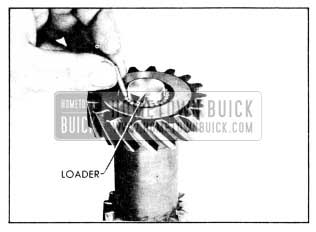

1956 Buick Installing Counter Gear Bearings with Loader

Pack bearing rollers in white vaseline to hold them in place and make certain that all rollers are installed (26 in each bearing). Leave loader in gear until it is pushed out by the counter gear shaft during installation.

When installing counter gear, place the steel thrust washer between the rear bronze thrust washer and boss in case. Drive counter gear shaft lock flush with surface of case.

- First and Reverse Sliding Gear. Install the first and reverse sliding gear so that “U” groove in one face of gear is toward front of 1956 Buick Synchromesh Transmission.

- Second Speed Gear. Install the small wire spacer ring in groove in main shaft before installing snap ring which retains the second speed gear thrust washer. This spacer centers the snap ring so that it projects equally all around the shaft.

- Synchronizing Clutch. The synchronizing clutch must be installed with the counterbored end toward the second speed gear to insure full engagement of clutch with gear and avoid slipping out of second speed. The second speed end of clutch is stamped with a letter “S.” Gear synchronizing clutches furnished for service have a figure “7” (to indicate 7° angle) stamped on the second speed drum. Do not use replacement clutch having any other number stamped on drum. See figure 4-23.

1956 Buick Counterbore and Marks on Second Speed End of Clutch

Leave A Comment

You must be logged in to post a comment.