SECTION 4-A 1956 BUICK CLUTCH

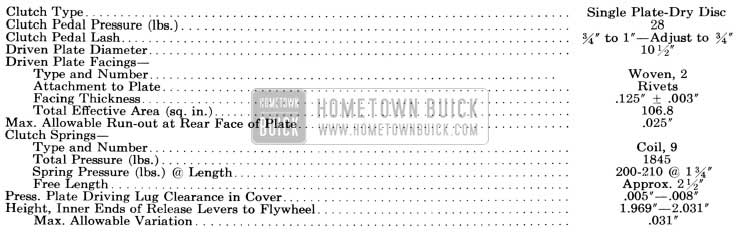

4-1 1956 BUICK CLUTCH SPECIFICATIONS

Tightening Specifications

1956 Buick Clutch Tightening Specifications

1956 Buick Clutch Specifications

1956 Buick Clutch Specifications

4-2 DESCRIPTION OF 1956 BUICK CLUTCH

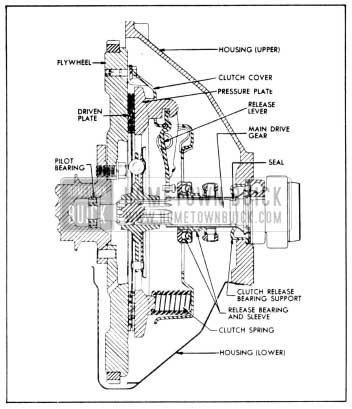

A single plate, dry disc clutch is used in cars equipped with synchromesh transmissions. The 1956 Buick clutch is of conventional design with coil type clutch springs and three release levers.

1956 Buick Clutch Assembly

The 1956 Buick clutch cover is bolted to the flywheel and three lugs on the pressure plate engage slots in the cover to transmit torque to the plate. Nine clutch springs are located between the cover and the pressure plate. The three clutch release levers are located so that their inner ends are in position to be engaged by the clutch release bearing. The levers pivot on fulcrums formed at the clutch cover where they pass through it. The outer er1ds engage the three pressure plate lugs. See figure 4-1.

1956 Buick Clutch and Flywheel Assembly

When the 1956 Buick clutch is in the engaged position, the release levers are clear of the release bearing and the clutch springs cause the pressure plate to clamp the driven plate against the flywheel with sufficient force to transmit power of the engine without slippage. The power drive is from flywheel to clutch cover, cover to pressure plate, and from pressure plate and flywheel to driven plate.

When the 1956 Buick clutch is disengaged, the clutch release bearing presses forward on the inner ends of the release levers which pivot at the clutch cover and force the pressure plate rearward against the pressure of clutch springs. The pressure plate is moved rearward far enough to free the driven plate. See figure 4-1.

1956 Buick Clutch Driven Plate

The 1956 Buick clutch driven plate assembly is mounted with a free sliding fit on the transmission main drive gear and is keyed to the gear by ten splines. The front end of the main drive gear is piloted by a ball bearing pressed into a recess on rear end of engine crankshaft. See figure 4-1.

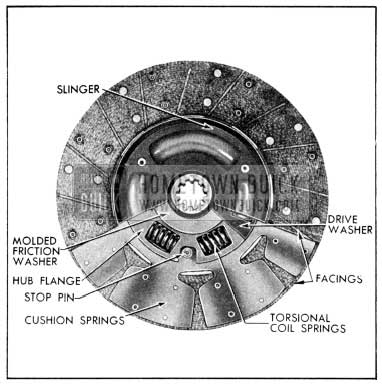

The outer area of the driven plate is divided into segments which are formed in low waves to provide springs between the plate facings and thereby cushion engagement of the 1956 Buick clutch. A woven facing, grooved to give quick release, is riveted to each side of every segment of plate. When the clutch is fully released, the waved segments cause the facings to spread approximately .050″ and the movement of pressure plate provides approximately .030″ clearance to assure full release of driven plate. See figure 4-2.

1956 Buick Driven Plate-Transmission Side

The driven plate assembly is designed to prevent torsional periods of the engine from being transmitted to the transmission gears and causing rattle. This is accomplished by driving the plate hub through torsional coil springs and providing frictional dampening by means of molded friction washers.

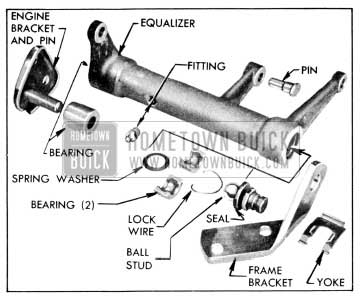

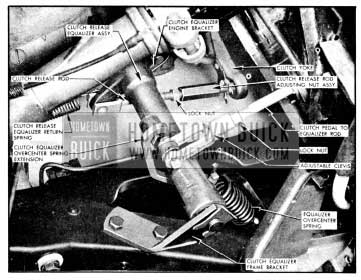

1956 Buick Clutch Release Mechanism

The 1956 Buick clutch pedal is the suspended type. It is mounted in a hinge bracket welded to the pedal plate and it pivots in nylon bushings in the pedal. Pedal movement is transmitted through a rod to the equalizer. The upper end of this rod is a ball which is retained in a nylon ball socket at the clutch pedal; the lower end has a clevis, a lock nut, and a clevis pin which is keyed to the outer arm of the equalizer. The purpose of the adjustable clevis is to correctly position the equalizer assembly in relation to the overcenter spring.

The 1956 Buick clutch equalizer permits smooth engagement of clutch without being affected by movement of the engine on its mountings. The inner end of equalizer is fitted with a rubber bushing which rotates on the pin of a bracket attached to engine. The outer end of equalizer rotates on a ball stud attached to car frame. A spring and two spring seats inside equalizer maintain pressure on the split bearings which support equalizer on stud ball. A lubrication fitting is installed on equalizer and seals inclose both ends to exclude dirt and water. See figure 4-3.

1956 Buick Clutch Release Equalizer-Disassembled

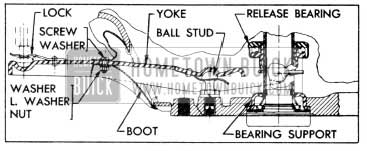

The inner arm of clutch release equalizer is connected by an adjustable rod to the outer end of the release yoke which is pivoted on a ball stud located in the flywheel housing. The yoke is held on the ball stud by a U-shaped spring riveted to yoke. A boot around the yoke provides a flexible closure for the yoke opening in flywheel housing. The inner end of release yoke is in position to push forward on the 1956 Buick clutch release bearing sleeve when clutch pedal is depressed. A U-shaped spring riveted to release bearing sleeve holds bearing sleeve in contact with yoke.

The 1956 Buick clutch release bearing and sleeve assembly is mounted upon a bearing support which encircles the transmission main drive gear. The bearing is filled with lifetime lubricant in production and no further lubrication is required. The bearing support is flared at the rear end to seat in flywheel housing and is held in place by a spring washer and the outer race of transmission main drive gear bearing. See figure 4-1.

A coiled return spring is connected between the clutch release rod clevis pin and the frame to keep the clutch release bearing out of contact with the clutch spring when clutch is engaged.

An over-center type actuating spring holds the pedal firmly against a rubber bumper on the toe board when 1956 Buick clutch is in engaged position, and helps to reduce pedal pressure as it goes over center when clutch is disengaged. The actuating spring is attached to the frame by an eye bolt and to a pin on clutch pedal by an extension which straddles the pivot point of pedal. The spring and extension are positioned so that the pedal is pulled upward in the free position and pulled downward when depressed to disengage the 1956 Buick clutch. See figure 4-4.

1956 Buick Clutch Linkage

4-3 1956 BUICK CLUTCH TROUBLE DIAGNOSIS

Excessive Pedal Pressure

The pressure required to depress 1956 Buick clutch pedal to toe board should not exceed 28 pounds. If pedal pressure is excessive, make certain that pedal rod is not binding in floor mat or toeboard. Thoroughly lubricate release equalizer with chassis lubricant. NOTE: Excessive pedal pressure may be caused by using excessive grease gun pressure on equalizer, which may force the rubber inner bearing out into contact with equalizer bracket on engine.

If excessive pedal pressure still exists after release linkage is properly lubricated, lubricate internal working parts of 1956 Buick clutch as described in paragraph 4-4.

1956 Buick Clutch Noise

Squeaking and grinding noises during 1956 Buick clutch pedal operation are usually caused by heavy friction in the release linkage or internal parts of clutch assembly. Before condemning the release bearing, thor011ghly lubricate release equalizer and, if necessary, lubricate internal working parts of clutch as described in paragraph 4-4.

1956 Buick Clutch Grab or Chatter

A very slight amount of oil on driven plate facings will cause clutch grab and chatter. A new driven plate must be installed if original plate facings contain oil since removal of oil from facings is not practical.

When oil is found on facings, examine pilot bearing, transmission drainback, rear engine bearing, and oil leaks which might drain back into clutch housing between upper and lower flywheel housings.

Improper variation in height of release levers will cause clutch chatter. To correct this condition, replace 1956 Buick clutch assembly (par. 4-5).

1956 Buick Clutch Drag or Failure to Release

To test for clutch drag or failure to release, depress clutch pedal to toeboard with engine running and shift transmission into low gear. Hold pedal depressed and shift transmission to neutral, wait about 15 seconds with pedal depressed and again shift into low gear. If 1956 Buick clutch is not releasing completely a gear clash will occur.

If test shows that 1956 Buick clutch is not releasing properly, check clutch pedal lash (par. 4-4) and check release linkage for lost motion. Correct as necessary and again test for clutch drag.

If clutch drag cannot be corrected in release linkage, remove clutch and check height of release levers. Check driven plate for oil soaked or cracked facings, also for run-out and free movement on main drive gear (par. 4-6).

1956 Buick Clutch Slipping

First make certain that 1956 Buick clutch pedal is adjusted for specified lash (3/4 to 1 in.) and that pedal is not binding. One type of clutch slippage is sometimes wrongly diagnosed as due to weak clutch springs. This slippage occurs during gear shifting and full engagement of the clutch is not obtainable until the engine speed is reduced. After full engagement is obtained no further slippage occurs during acceleration or under full load. This condition is usually due to the clutch driven plate hub sticking on the splines of the transmission main drive gear. Correction can be made by removing the clutch and thoroughly cleaning splines of driven plate and main drive gear then applying a light coating of Lubriplate. Make sure that release lever pins are not binding, and that pressure plate driving lugs are not binding in clutch cover.

4-4 1956 BUICK CLUTCH ADJUSTMENT AND LUBRICATION

1956 Buick Clutch Pedal Lash Adjustment

It is very important to maintain proper clutch pedal lash at all times. Insufficient pedal lash will cause pressure of release bearing against the clutch release levers, resulting in abnormal wear of these parts; it may also cause clutch slippage and abnormal wear of driven plate if pressure is great enough to prevent positive engagement of 1956 Buick clutch.

- Make certain that the return spring pulls clutch pedal washer firmly against bumper on toe board when pedal is released. If pedal washer does not contact bumper check pedal and linkage for binding or lack of lubrication. Check condition of equalizer return spring. Check condition of actuating spring and make sure that spring eye bolt is fully tightened.

- Check for correct position of equalizer assembly by measuring between equalizer overcenter spring extension and equalizer. If clearance is not 1/16″ to 1/8″, loosen pedal to equalizer rod lock nut and rotate rod to obtain correct clearance. Then retighten lock nut. NOTE: This adjustment will ordinarily be necessary only when installing new linkage parts. Adjust pedal lash at the lower clutch release rod as described in following paragraph.

- Check pedal free movement or lash by pushing on pedal pad until release bearing contacts clutch levers. Do not mistake tension of pedal return spring as an indication of lack of pedal lash. Free movement or lash of clutch pedal should be 3/4″to 1″, measured at pedal pad.

- If adjustment is necessary, loosen lock nut and turn adjusting nut on clutch release rod as required to secure 3/4″ lash, then tighten lock nut securely. See figure 4-5.

1956 Buick Clutch Release Yoke and Boot

Lubrication of 1956 Buick Clutch Internal Parts

Lubrication of 1956 Buick clutch release equalizer and linkage is included in Lubricare every 1000 miles (par. 1-1). Lubrication of clutch internal working parts is usually required only at time clutch is assembled and installed; however, if lubrication becomes necessary to eliminate squeaks or excessive pedal pressure, proceed as follows:

- Remove flywheel lower housing.

- Disconnect rod from clutch release yoke, unhook boot from opening in flywheel upper housing, and pull yoke outward to disengage it from ball stud. See figure 4-5.

- Apply Lubriplate or Delco Brake Lubricant to ball stud and ball seat in yoke, then connect yoke to ball stud. Hook boot to opening in flywheel housing and connect release rod to yoke.

- Examine clutch release bearing sleeve to see whether it is binding on release bearing support due to improper installation. Lubricate any contact point between bearing sleeve and support by brushing with Lubriplate or Delco Brake Lubricant.

- Brush lubricant on pressure plate driving lugs where they contact cover. Work clutch pedal a number of times to work lubricant into contact points.

Rotate flywheel until each release lever in turn is in lowest position, then very sparingly oil the release l ever fulcrums and sides of release levers. Allow time for any surplus oil to drain off before turning flywheel, to avoid getting oil on driven plate facings. Release lever fulcrums also may be lubricated by spraying with powdered graphite, which will not damage driven plate facings. This may not afford immediate relief but if 1956 Buick clutch is operated while engine is running, after installation of flywheel lower housing, the graphite will work into the bearing surfaces.

- Install flywheel lower housing.

4-5 REMOVAL AND INSTALLATION OF 1956 BUICK CLUTCH

Removal of 1956 Buick Clutch

- Remove rear axle assembly (par. 6-4) and transmission (par. 4-13). Remove flywheel lower housing.

- Disconnect release rod from release yoke and remove yoke boot and release rod nut lock which are bolted to yoke. See figure 4-5.

- Remove spring washer which retains release bearing support in flywheel housing and remove support and gasket.

- Pull outward on release yoke to free it from the ball stud in flywheel housing and remove yoke and release bearing through bottom of housing. Separate yoke from bearing.

- Mark the 1956 Buick clutch cover and the flywheel with a center punch so that cover can be reinstalled in the same position on flywheel in order to preserve engine balance.

- Loosen each clutch cover bolt a little at a time in order to relieve clutch spring pressure evenly and avoid distortion of cover. Metal spacers placed between release levers and inner edge of clutch cover will aid removal and later disassembly by holding clutch springs compressed.

- Support pressure plate and cover assembly while removing the last bolts, then remove the assembly and driven plate.

Installation of 1956 Buick Clutch

- Very sparingly apply front wheel bearing lubricant to main drive gear pilot bearing in crankshaft. If too much lubricant is used it will run out on face of flywheel when hot and ruin driven plate facings. Make sure that surface of flywheel is clean and dry.

- Make sure that splines in driven plate hub are clean and apply a light coating of Lubriplate. Driven plate facings must be clean and dry.

- Place driven plate on pressure plate with oil slinger toward pressure plate, then place 1956 Buick clutch assembly in position against flywheel, being sure to align marks made on flywheel and cover before removal. Install cover bolts with lockwashers but do not tighten bolts.

- Insert a spare main drive gear through hub of driven plate and into the pilot bearing. Tighten each clutch cover bolt several turns at a time to draw cover evenly into pilot of flywheel and avoid distortion of cover. While tightening cover bolts, move main drive gear from side to side to center driven plate with pilot bearing. If plate is not properly centered it will be difficult to slide transmission into place. Make sure all cover bolts are uniformly tightened.

- Remove spacers from between cover and release levers.

- Fill groove in release bearing sleeve with wheel bearing lubricant. Coat release yoke ball stud and ball recess in release yoke with Lubriplate or Delco Brake Lubricant. Attach release bearing to release yoke and attach yoke to ball stud in flywheel housing.

- Install release bearing support with a new gasket, placing support in flywheel housing with the tab on support alined with molded recess in housing to permit positive drain back of oil to transmission. Install spring washer with outer edge against bearing support.

- Install transmission (par. 4-13), being sure to use Guide Pins J 851 to avoid damage to 1956 Buick clutch driven plate which would result if weight of transmission is allowed to rest on main drive gear in driven plate hub.

- Install boot and release rod nut lock on yoke (fig. 4-5), attach release rod to yoke, then adjust for clutch pedal lash of 3/4″ (par. 4-4).

- Install flywheel lower housing, making sure that gasket is in condition to insure a tight seal. Install rear axle assembly (par. 6-4).

- Road test car for 1956 Buick clutch performance.

Under no circumstance should the clutch be harshly used immediately after installation of a new driven plate, flywheel, or pressure plate. Sudden engagement of clutch with engine running at abnormal speed, or continual slipping of clutch, may permanently injure driven plate facings and may cause scoring of flywheel and pressure plate. When these parts are new they must be given moderate use for several days until nicely burnished. Be sure that car owner is advised of this requirement.

4-6 INSPECTION OF 1956 BUICK CLUTCH

Wash all metal parts of 1956 Buick clutch, except release bearing and driven plate, in suitable cleaning solution to remove dirt and grease. Soaking release bearing in cleaning solution may permit solution to seep into bearing and destroy the lubricant. Soaking driven plate in cleaning solution may damage the facings.

- Flywheel and Pressure Plate. Examine friction surfaces of flywheel and pressure plate for scoring or roughness. Slight roughness may be smoothed with fine emery cloth, but if surface is deeply scored or grooved the part should be replaced.

- Clutch Cover. Inspect clutch cover for cracks or distortion. Check clearance between pressure plate driving lugs and edges of slots in cover, using feeler gauges. The clearance should be .005″ to .008″; excessive clearance may cause rattle when engine is intermittently accelerated with 1956 Buick clutch disengaged.

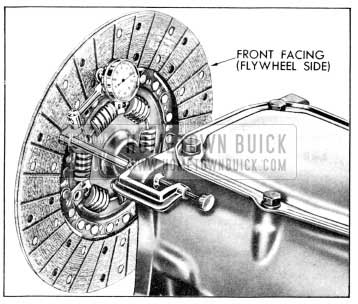

- Clutch Driven Plate. Inspect driven plate for condition of facings, loose rivets, broken or very loose torsional springs, and flattened cushion springs. See figure 4-2.

If facings are worn down near rivets or are oily, the plate assembly should be replaced. A very slight amount of oil on clutch facings will cause clutch grab and chatter. A large amount of oil on facings will cause slippage or drag. Removal of oil by solvents or by buffing is not practical since oil will continue to bleed from facing material when hot.

When oil is found on driven plate facings, examine transmission drainback hole, pilot bearing, engine rear bearing and other points of oil leakage.

Test the fit of driven plate hub on transmission main drive gear; an easy sliding fit should exist. Regardless of whether the old plate or a new one is to be installed, the plate should be checked for run-out. This check can be made by sliding the driven plate, front side first, over the transmission main drive gear until it is tight on the spline, then setting up a dial indicator to bear against the plate facing as shown in figure 4-6.

1956 Buick Checking Driven Plate for Run-out

While holding firmly against front end of main drive gear to take up play in main drive gear bearing, slowly rotate driven plate and observe the amount of run-out shown by indicator. If run-out of front facing exceeds .025″ the plate should not be used since it is not practical to correct excessive run-out by bending.

- Inspect 1956 Buick clutch release bearing for scoring or excessive wear on front contact face. Test for roughness of balls and races by pressing and turning front race slowly. Inspect main drive gear pilot bearing in crankshaft. If bearing is rough or worn it should be replaced, using Puller J-164 for removal.

Leave A Comment

You must be logged in to post a comment.