SECTION 11-B 1956 BUICK HEATER, AIR CONDITIONER

11-6 1956 BUICK HEATER AND DEFROSTER

1956 Buick Heater Installation Description

The combination heater and defroster core and housing is mounted low on the right side of the cowl between the cowl side panel and the right front fender. This high capacity core serves both the 1956 Buick heater and defroster systems which differ only in distribution of the heated air. The hot water is supplied to this core directly from the thermostat housing in the engine water manifold. It enters the bottom of the heater-defroster core and leaves at the top where it is conducted through a hose directly to the temperature control valve described in subparagraph e. A hose then carries the water back to enter the radiator at the right side of the lower tank.

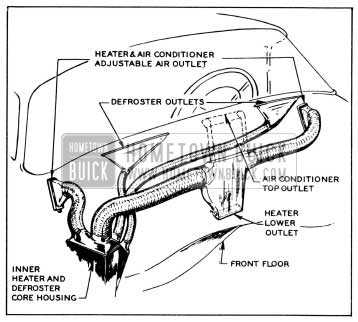

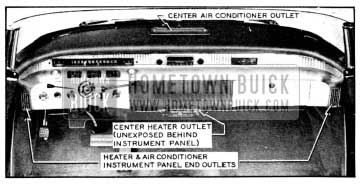

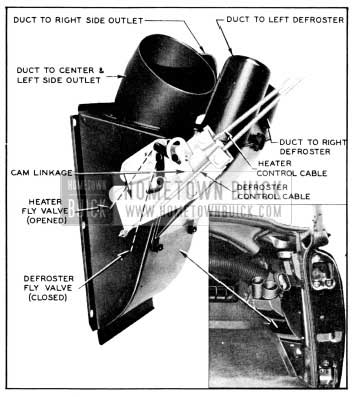

The blower located on the engine side of the right ventilator air duct cover, draws outside air through the cowl air intake screen and into the right air duct. The air is then forced from the blower into an air tube which delivers it to the 1956 Buick heater-defroster core. The air flows through the heater-defroster core into the inner heater and defroster core housing where it may be directed into either the heater or defroster distribution system by means of two fly valves. For heating, the air is directed through the heater air distribution system to three heater outlets. One is located at each end of the instrument panel and the third outlet is located below and behind the center of the instrument panel. See figure 11-12.

1956 Buick Heater, Defroster and Air Conditioning Outlets

The 1956 Buick heater-defroster system uses only outside air. However, when an air conditioner is installed, some interior air is recirculated.

1956 Buick Defroster and Outside Air Ventilation

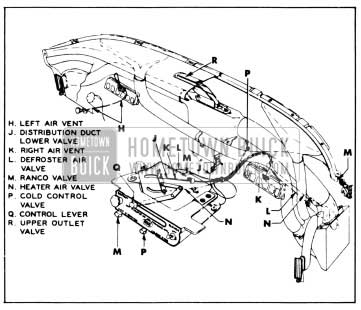

For defrosting, the air is directed from the inner heater-defroster core housing through separate defroster air hoses to two wide defroster outlets at the windshield. All the air may be directed through either the heating or the defrosting distribution system, or the air may be partially directed through both depending on the position of the two valves. See figure 11-24.

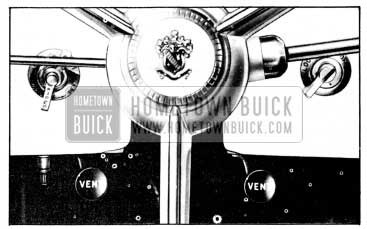

1956 Buick Outside Air Vent Controls

Two ventilation air vents are located on the lower dash panel, one on each side of the front compartment. The valves incorporated in these vents are controlled by two push-pull control knobs located on each side of the steering column at the lower edge of the instrument panel.

Water Flow and Temperature Control Valve

The hot water flows from the engine water manifold through a hose into the bottom of the 1956 Buick heater-defroster core. Water then flows out of the heater-defroster core, at the top, through a hose to the Ranco valve. From the Ranco valve, water flows through a hose to the bottom of the radiator.

The system is equipped with 3/4″ I.D. hoses and 3/4″ Ranco valve.

A “jiggle pin” in the bleed hole of the engine thermostat allows air to escape through the bleed hole when filling the system, but seats, closing off the bleed hole when the water pump creates a small amount of pressure. The “jiggle pin” prevents water from circulating through the bleed hole and thereby facilitates quicker warm-up when engine is cold. The quicker warm-up supplies hot water more rapidly to the 1956 Buick heater-defroster core.

1956 Buick Heater, Defroster and Ventilation Controls

1956 Buick Heater and Defroster Controls

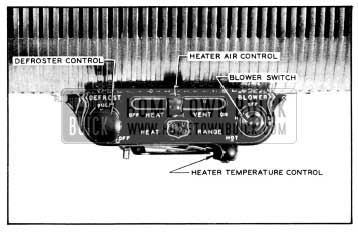

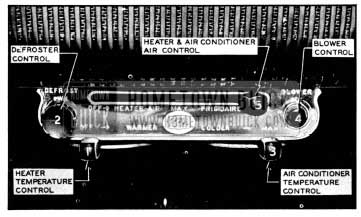

Figure 11-14 shows the control panel which is used with the 1956 Buick heater and defroster installation. Figure 11-32 shows the control panel used with the air conditioner installation. Although the controls are positioned slightly different when an air conditioner is installed, the controls operate in the same manner as they do when only the heater and defroster are installed.

The defroster control knob is of a push-pull type and the pull knob is attached to a fly valve in the inner heater and defroster core housing by means of a control wire. When the defroster knob is pulled out, the defroster valve opens and allows air to flow into the two defroster distribution air hoses. Figures 11-14 and 11-22 show the location of the defroster controls.

The blower speed is controlled by a toggle switch located on the right side of the control panel. See figures 11-14 and 11-22. The switch has 3 positions, “Hi,” “Off,” and “Lo.” The 1956 Buick heater temperature control lever, as shown in figure 11-14 and 11-22 regulates the temperature of the heater air entering the passenger compartment and is connected to the Ranco valve by a control wire. As the temperature control lever is moved from left to right the heater temperature is increased.

The 1956 Buick heater air control (upper lever) as shown in figure 11-14, when moved to the right, opens the heater valve in the inner heater and defroster core housing and allows air to flow into the heater air distribution system.

Inner Heater and Defroster Core Housing

The 1956 Buick heater and defroster valves located in the inner heater and defroster core housing are operated by a cam type linkage which is designed to prevent valve flutter noise. See figure 11-24.

NOTE: To keep out offensive traffic odors and exhaust gases when traveling in congested traffic or when parked behind a car having its engine running, all ventilator and defroster valves must be closed and the blower must be turned off.

WARNING-CARBON MONOXIDE

Avoid inhaling exhaust gases when any concentration of these is present in the air, i.e., in a garage, in congested traffic, or when stopped closely behind a vehicle with its motor running. Exhaust gases may have strong odors which normally should give warning of their presence. However, the exhaust gases from some vehicles may not be noticeable under certain conditions and the senses of people react differently. Exhaust gases contain a percentage of carbon monoxide, which is a poisonous gas that, by itself, is tasteless, colorless, and odorless.

Temperature Control Valve Wire Adjustment

The temperature control valve is operated by a lever through a sheathed operating wire. To insure full range of temperature control, the valve must act as the stop at both ends of lever travel. Since the operating wire is of fixed length with loops at each end, full range of operation is obtained by clamping the operating wire sheath in proper location on the control lever support and the temperature control assembly as follows:

- Connect operating wire to control lever and clamp end of sheath approximately 1 1/2″ from edge of clamp on lever support.

- Turn temperature control valve all the way clockwise until the cam locks against the roller. This is the extreme “off” position. Connect operating wire to brass post on valve and clamp the sheath to valve assembly.

- Operate the control lever through full range to make certain that the valve provides the stop at both ends.

11-7 1956 BUICK AIR CONDITIONER

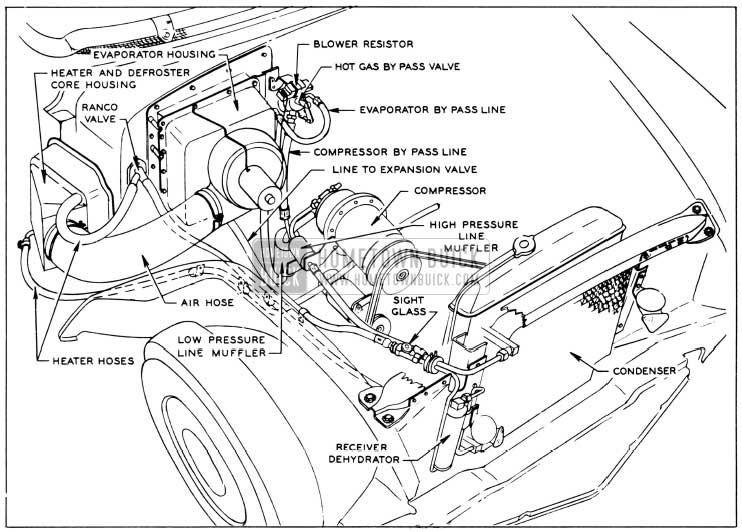

The 1956 Buick Air Conditioner is dash-mounted with all the components located in or ahead of the dash. The 1956 Buick air conditioner compressor and condenser are located as shown in figure 11-15.

1956 Buick Air Conditioner Installation

The receiver-dehydrator tank is vertically mounted along the right side of the condenser. The evaporator with its case and blower are mounted forward of the dash panel on the right side. All units are joined with high pressure hoses provided with double flare fittings. Units provided for field installation come already connected together and charged with 5 1/2 pounds of Freon 12, and are installed as a unit without breaking any of the connections. The 1956 Buick air conditioner uses the same air distribution system as the heater with an additional outlet on top of the upper instrument panel.

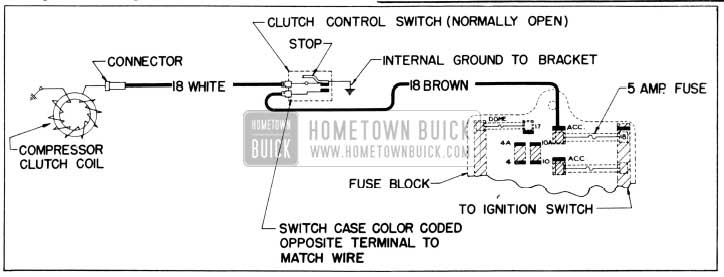

Locations of the various units of the 1956 Buick Air Conditioner system and their connecting hoses are shown in figure 11-15. Figure 10-84 shows the electrical control circuit, which is entirely separate from all other chassis and body wiring.

Any service work that requires breaking a pipe joint or hose connection should be performed only by mechanics who have been trained in Buick or other automotive air conditioning schools. Whenever a hose is disconnected from any unit refrigerant will escape unless the proper procedure is used. Any work involving the handling of refrigerants requires special equipment and a knowledge of its proper use.

Description of Components

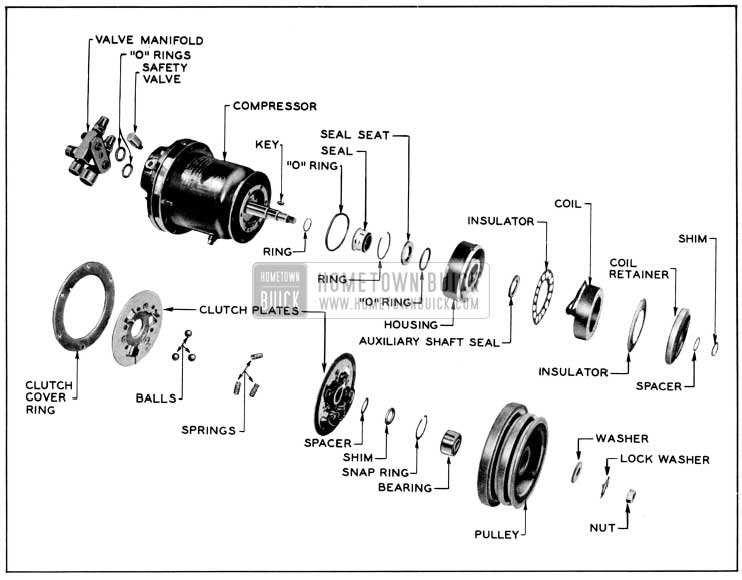

- Compressor and Clutch. The axial piston type compressor is mounted on the right-front of the engine, over the generator. The compressor to engine speed ratio is approximately 1.25 to 1.

The mufflers are located in each compressor attaching line, one in the suction line and one in the discharge line. They consist of cylinders approximately 2 1/2″ in diameter by 3″ long containing interior baffles that greatly reduce the characteristic pumping sounds of this compressor.

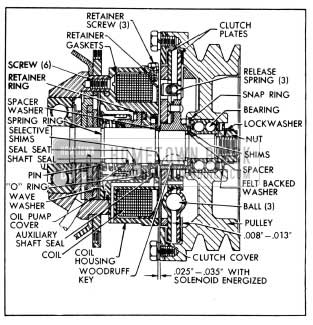

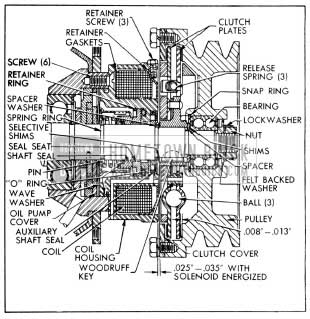

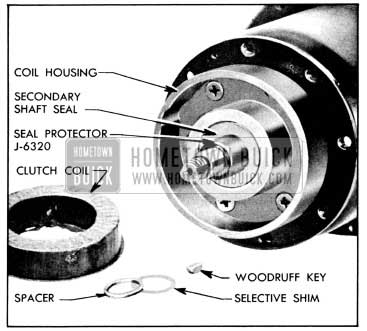

The 1956 clutch and seal parts are not interchangeable with past model parts. The main shaft seal seat is located ahead of the seal body. The clutch hub is retained to the main shaft by a woodruff key and a press fit. The pulley bearing is also a press fit to the shaft and is retained in the pulley by a snap ring. See figure 11-16.

1956 Buick Compressor Clutch and Pulley

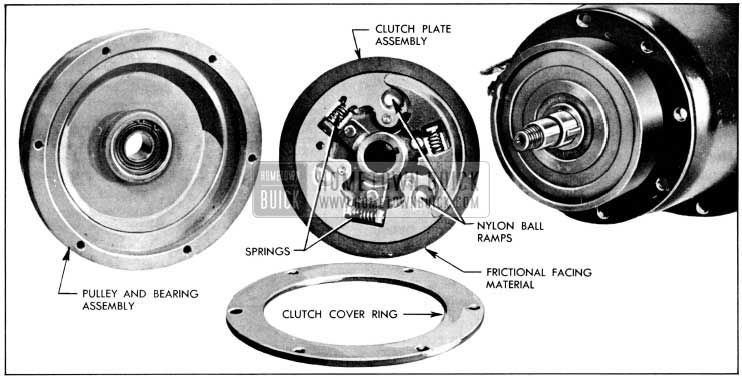

The compressor clutch is actuated by an electro-magnetic coil housed between the clutch and pulley assembly and the compressor housing. Two dry disk clutch plates, separated by three nylon balls, are used. Each plate has a flat ring of frictional material bonded to its contact face. The forward clutch plate is fixed to the compressor main shaft by a woodruff key and press fit. The clutch plates are connected to each other only through three small coil springs, positioned to oppose the torsion of the driving force.

When the coil is energized a magnetic field is created which attracts the rear clutch plate and pulls it into contact with the clutch cover ring. The frictional forces overcome the three torsion springs (See figure 11-17) and cause enough relative rotation between the clutch plates to make the nylon balls roll up their ramps, spreading the clutch plates apart and forcing them into firm contact with their mating surfaces.

1956 Buick Compressor Clutch and Disc Assembly

This provides a solid connection between the pulley and the compressor main shaft.

When the clutch coil is de-energized, the magnetic field collapses and the rear clutch plate is no longer held against the clutch cover ring. The three coil springs overcome the servo-action of the nylon balls and force the clutch plates into a neutral position, disengaging the pulley from the main shaft.

The oil checking fitting is a fitting similar to a brake bleeding screw.

- The connecting elements are made from a high temperature, high pressure synthetic rubber hose with double cord reinforcements. The hose ends are fitted with double flare fittings. The hoses are of sufficient length to be adaptable to all models in all series.

- Condenser and Receiver-Dehydrator. The condenser is mounted ahead of the radiator. The receiver-dehydrator tank is attached directly to the right side of the condenser frame along with a horn mounting pad. A sight glass is located in the liquid line from the receiver dehydrator, immediately behind the right radiator side baffle.

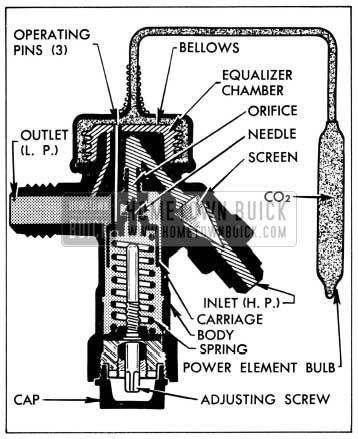

- Thermostatic Expansion Valve. The expansion valve is located at the bottom of the evaporator core on the outside of the case. The liquid enters the valve at the 3/8″ flare fitting, passes through the needle seat orifice, and leaves the valve at the 1/2″ flare connection and enters the evaporator. See figure 11-18.

1956 Buick Expansion Valve Cut-Away

The power element or bellows cap of the valve is connected by a capillary line to a thermo bulb which is clamped on the low pressure line between the evaporator coil and the low pressure line muffler.

- Evaporator and Blower. The evaporator core measures approximately 10″x10″x3″ thick and consists of an aluminum brazed plate type coil. This coil is housed in a plastic impregnated fibre glass (Formadall) case which is mounted to the dash panel on the right side in the engine compartment, replacing the right hand ventilation air duct cover.

The blower assembly mounts directly to the evaporator housing, on the front side, and is connected to the outer heater core housing by a large insulated flexible air tube.

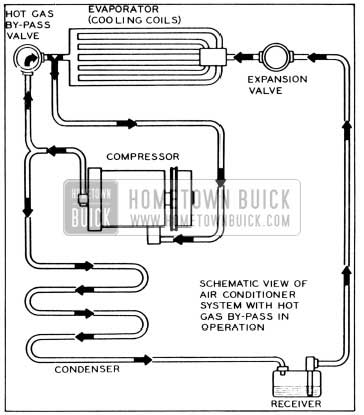

- Hot Gas By-pass Valve. Figure 11-19 is a schematic view of the operating refrigeration cycle using the hot gas by-pass valve and showing this valve’s relative position in the system.

1956 Buick Air Conditioning System-Schematic

The manually controlled hot gas by-pass valve is located on the evaporator to compressor suction line near the evaporator outlet.

It is also connected to the compressor high pressure (discharge) line between the compressor and the condenser. The temperature of air coming out of the evaporator may be controlled between approximately 43° and 60° by varying the air conditioner temperature control lever which is connected to this valve.

The valve accomplishes this temperature control by metering hot high pressure Freon from the compressor discharge line into the low pressure (suction) line near the evaporator outlet. By this metering the valve maintains any pre-determined minimum evaporator outlet (Freon) pressure between approximately 29 and 55 psi. The pressure regulation in turn affects the thermostatic expansion valve which varies the metering of liquid Freon into the evaporator coil. As the cooling of the air passing through the evaporator coil depends directly upon the quantity of liquid Freon that is allowed to expand (evaporate) in the coil, the conditioned air temperature is effectively controlled.

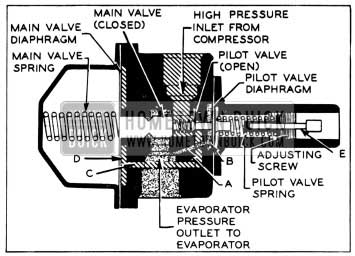

The operating pressure of the hot gas by-pass valve is set by means of the adjusting screw which compresses the pilot valve spring. See figure 11-20.

1956 Buick Hot Gas By-pass Valve-Sectional

This spring pressure is opposed by the evaporator pressure acting on the pilot valve diaphragm through passage “A”. Using 29 psi as the desired evaporator pressure which will prevent freezing, the following takes place: as long as conditions are such that the evaporator pressure is more than 29 psi, the pressure in Area “B” opposes the pilot valve spring and the unit is sealed and has no effect on the system. When the evaporator pressure drops to the 29 psi setting, the pilot valve spring opens the pilot valve allowing gas at head pressure to pass through passage “C” and apply against the main valve diaphragm in Area “D” which compresses the main valve spring and moves the main valve from its seat permitting gas to pass through to the suction line. These valves position so as to permit enough flow of hot gas to maintain the 29 psi setting. This setting has been referred to as “freeze protection.” If a higher temperature is desired, or less cooling, the pilot valve spring is compressed further than “freeze protection” by means of a Bowden wire and lever acting on pin “E”. Then the same “metering” cycle takes place but at a higher pressure and, consequently, higher temperature.

- Air Distribution System. The air conditioner air distribution system makes use of the heater air ducts and outlets at the outer ends of the instrument panel plus an additional outlet located at the top center of the instrument panel.

The outlets on either end of instrument panel are adjustable. They may be adjusted to direct air up, down, inward toward the center of the car, or outward toward the door panels. Heated or air conditioned air is circulated to the rear seat area when the instrument panel outlets are adjusted so that air is directed along the door panels. See figure 11-21.

1956 Buick Air Distribution System Dash View

As both the 1956 Buick air conditioning and 1956 Buick heater-defroster systems are dash-mounted it is possible (on cars so equipped) to operate both systems simultaneously to effect dehumidification of the ventilation air when neither heating nor cooling are required. When the air conditioning system is in use the right air vent (under the instrument panel) is converted to a return air duct to provide the evaporator blower with cooled air to recirculate. This results in lower car temperatures than are possible with systems using 100 % outside air. All outside air introduced (25 %) is filtered by a single filter located in the evaporator housing. This filter is easily removable from the top for cleaning or replacement. This maintenance operation should be performed every 1,000 miles or oftener under extremely dusty conditions.

Outside air is used exclusively for heating when an air conditioner is not installed. Recirculated air, along with outside air is used when an air conditioner is installed. A fixed orifice in the evaporator case proportions the outside air to total air that is to be air conditioned. The right outside air vent valve is automatically opened to allow recirculation when the air conditioning unit is operating.

A spring loaded pressure relief valve in the right outside air vent valve is necessary to prevent cold air from entering the car when the 1956 Buick heater blower is off. This valve is used only when air conditioning unit is installed, permitting air to recirculate and enter the heating core when the heater blower is on.

- Lower left lever (1) is the heater-defroster temperature control, shown in “OFF” position. (Figure 11-22.)

1956 Buick Air Conditioner Control Panel

Operation

To place the 1956 Buick air conditioner in operation (cooling):

- Make sure left fresh air vent and defroster are closed.

- Move the lower left control lever (heater temperature) to the “OFF” position.

- Move the upper (air) control lever to the extreme right position.

- Turn “BLOWER” switch on as required (Hi or Lo), and adjust instrument panel top and end vents as desired. After allowing several minutes of operation for unit and car interior temperatures to stabilize, move lower right (temperature) control lever to obtain desired temperature. For maximum cooling all windows should be closed.

If dehumidification is required without cooling move the lower left control lever toward the right until the desired temperature is obtained. This must be done with the air conditioner in operation as described in steps 1, 3 and 4 above. Dehumidification consists of cooling the incoming air (which removes most of the moisture) then re-heating to the desired comfort level.

Adjustments

- Hot gas by-pass Control Adjustment. To adjust the temperature control linkage, set the temperature control (right hand) lever on the lower edge of the control panel to “Max.”. Disconnect Bowden wire loop from pin on lever of hot gas by-pass valve. Push lever on bypass valve all the way toward the dash and release slowly. Lever will stop in “Max.” cooling position. Adjust Bowden wire sheave so loop matches position of pin on lever. Clamp Bowden sheave in position with loop encircling pin.

In the event that it becomes necessary to adjust the hot gas by-pass valve adjusting screw (See fig. 11-20) to correct the suction (back) pressure, the following procedure should be used:

1956 Buick Controls and Linkage

- Disconnect the valve control wire.

- Remove valve control lever and counterbalance spring.

- Connect service (high and low pressure) gauges to compressor.

- Set engine speed at 1600 RPM, turn unit on and allow time for stabilization.

- Turn adjusting screw in or out to obtain proper 28-30 lb. reading on the suction (back) pressure gauge.

- Remove gauges, replace protective caps, control pin, lever and spring and then re-adjust and connect control wire as outlined above.

- Thermostatic Expansion Valve. The design setting of the expansion valve is 5 turns out (counterclockwise) from the fully closed position. If the valve does not function properly at this setting, and if it has been definitely established that the trouble is in the expansion valve-replace the valve.

- Control Adjustments. The 1956 Buick Heater and Air Conditioner Air Control (5 in fig. 11-22) is adjusted by positioning the control lever directly over the letter “X” in “Max” on the control panel and clamping the bowden wire sheaves in the proper position as outlined below. With Air Control (5) in the above position:

- The center heater air distributor valve should be in full open position.

- The heater air valve (in the heater core inner housing) should be full open (with the defroster air valve closed). See figure 11-24.

1956 Buick Heater and Defroster Core Inner Housing

With defroster control knob (2) pushed all the way in the defroster air valve should be completely closed. Adjust cable sheave so that the control knob (2) does not quite touch the control panel when valve is completely closed.

For adjustment of heater temperature control wire refer to par. 11-6, subpar. f.

11-8 COMPRESSOR SERVICE PROCEDURES

NOTE: Before the engine is raised or lowered for any service operation the high and low pressure valves with lines attached must be disconnected from compressor, as described in subparagraph a, steps 1 through 6.

Removal and Installation of Compressor

CAUTION: Observe precautions in handling Freon-12 outlined in Buick Air Conditioner Manuals.

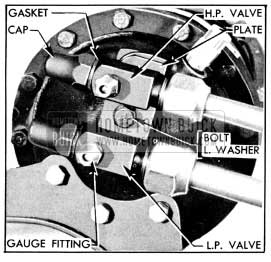

- Remove protective caps from gauge fittings of high and low pressure valves on rear end of compressor.

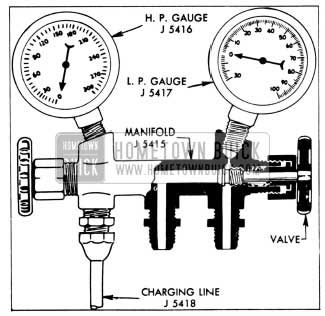

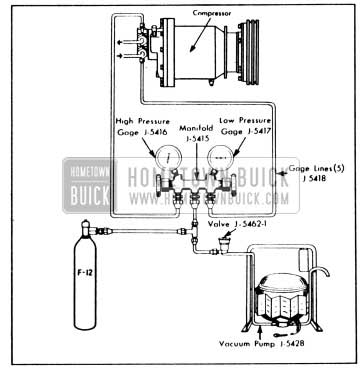

- Connect charging lines of Pressure Gauge Set (fig. 11-25) to gauge fittings of both valves, with both valves of Manifold J 5415 closed.

1956 Buick Pressure Gauge Set

1956 Buick High and Low Pressure Service Valves

1956 Buick Clutch and Shaft Seal-Sectional View

Do not place compressor in sun or near heat because it still contains some Freon-12.

- Install compressor by reversing procedure for removal, paying attention to the following points.

- Inspect drive belts and pulley grooves for conditions that might cause slippage. If a belt is cracked, frayed, or oil soaked, or is worn so that it bottoms in pulley grooves, replace both belts. Belts are furnished in matched sets only, to insure even tension.

- Adjust drive belts to 1/2″ deflection midway between fan and compressor pulleys.

See figure 10-10. - Use new „O“ rings when attaching valve assembly to compressor.

- Before starting compressor make sure that both valves are fully opened.

- After operating compressor for ten minutes at 1750 RPM, leak test around the valve mounting plate.

Removal and Installation of Clutch and Pulley

Observing the precautions on handling Freon, remove compressor as per instructions contained in preceding paragraph, and transfer compressor to work bench. If service work is to be done on the car, see subpar. d.

- Bend the tangs on the shaft lock washer to clear the flats on the shaft mounting nut. Loosen the six screws in the clutch cover ring. Energize the clutch coil from a 12 volt D.C. source to hold the compressor shaft and clutch assembly. Remove the nut. Remove the metalfelt washer.

- Remove the six screws and lock washers used to mount the clutch cover ring to the pulley casting. NOTE: It is absolutely necessary that this be done at this time to avoid damage to the internal parts of the clutch. It is also necessary to remove the three coil retaining screws to allow the clutch cover plate to move back.

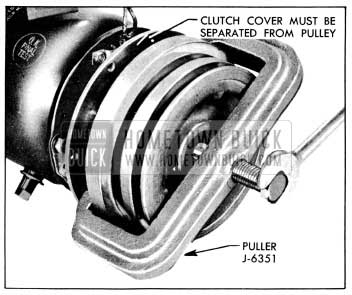

- Remove the pulley and ball bearing assembly with Compressor Pulley Puller J-6351.

1956 Buick Removing Pulley

NOTE: The I. D. of the ball bearing has a .0001″ to .0006″ press fit onto the first step of the compressor shaft.

- Remove the hub to pulley bearing spacer washer and shims and set aside. The clutch hub to bearing spacer washer and shims may be re-used on the assembly providing the original parts are being re-assembled. However, if it is necessary to replace either clutch plates, pulley, bearing, or if parts are being assembled on a service replacement compressor, a different combination of spacing shims may be required. This shimming is necessary to obtain the .008 to .013 clearance between the friction material on the clutch plate and pulley face, in the disengaged position.

NOTE: This clearance must be obtained before the clutch assembly and the pulley are pressed onto the shaft.

To obtain the clearance:

- Place the pulley and bearing assembly on a flat surface of the work bench.

- A combination of the shims listed here when used with the bearing spacer washer #5918343 (.088 +/- .002) will provide the .008 to .013 clearance.

- 5918366 – .010

- 5918367 – .015

- 5918368 – .020

- 5918369 – .025

- Select any suitable combination for trial use, and place these shims on the inner race of the ball bearing, then place the bearing spacer #5918343 on the shims. Now place the clutch plate assembly in the pulley, so that the hub is in contact with the spacer and shims.

Press down firmly at the center of the hub. Rotate the clutch plate assembly. If a very slight “drag” of the friction material is noticed, this will indicate that an insufficient thickness of shims is present in the assembly. Select a different combination and repeat check. If a heavy “drag” is felt, thicker shims must be selected in order to secure the very slight “drag.” If no “drag” at all is felt, thinner shims should be selected, to obtain the very slight “drag.” When this condition is obtained, determine the total thickness of the shims now assembled. Either add an additional .010 shim or replace one of the shims with a .010 thicker shim.

This will be the correct spacer and shim combination to complete the assembly to the compressor. After the clutch assembly is pressed on the shaft, place the thick spacer on first and then the correct thinner shims. This will prevent the shims dropping into the undercut near the shaft shoulder.

- Examine the O.D. of the shaft and the I.D. of the ball bearing for any evidence of wear, scoring or pitting (fretting corrosion). Replace ball bearing in pulley casting if necessary.

- To replace the ball bearing, remove the Truarc retaining ring, using Truarc pliers #3. Press out the ball bearing from the pulley and replace by pressing in a new bearing. NOTE: It is important upon reassembly to have the beveled side of the snap ring to the outside, or away from the ball bearing.

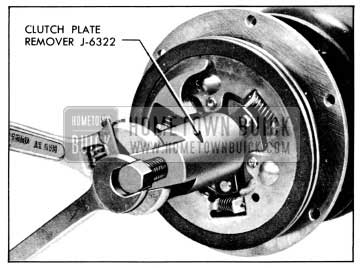

- The clutch plate assembly can now be removed by screwing on the special Clutch Plate Puller nut into which the Clutch Plate Puller screw has been assembled. (Tool J-6322). The cone point of this screw will center in the end of the compressor shaft. Rotate the screw with a wrench until the clutch plate assembly is pulled off of the shaft and woodruff key.

- Remove the woodruff key and air gap adjusting shims and spacer washer. Retain these parts for re-use, if the same clutch pulley parts are being reassembled. If clutch pulley parts are being transferred to a service replacement compressor, a different combination of shims may be required to obtain the .025 to .035 air gap between armature and coil housing when coil is energized by 12 volts D.C. The service replacement compressor clutch will have sufficient number of various thickness shims to obtain the correct air gap.

- Disassemble the actuating springs from the clutch plates. Examine the frictional surfaces for wear. Replace plate assemblies as necessary. Wipe plates with a clean, dry, oil free cloth. CAUTION: Do not use any cleaning solvents on the frictional surfaces, as it will result in unsatisfactory operation of the clutch upon reassembly. Examine the nylon balls that actuate the clutch. If any of the balls are deformed, excessively worn or damaged, replace all th1’ee.

- Install the three coil retaining screws, place the clutch cover ring against the coil and seal housing.

- Install the clutch spacer and air gap control shims on the shaft against the shoulder. Replace the woodruff key, tapping it lightly to seat it and properly align it.

- Reassemble the nylon balls and clutch plate springs to complete the assembly of the clutch plates.

- Align the key slot of the clutch hub with the woodruff key in the shaft of the compressor. . Make very certain that this alignment is maintained during the next four steps.

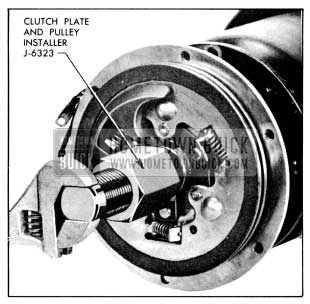

- The clutch plate assembly is now ready to be pressed on the shaft, using tool J-6323.

1956 Buick Removing Clutch Plates

See figure 11-30.

1956 Buick Installing Clutch Plates

- Screw the threaded stud into the adapter.

- Screw the adapter and stud on the threaded end of the compressor shaft, to its full travel.

- Apply a wrench to the hexagonal faces of the adapter. (NOTE: The adapter and stud have a LEFT hand thread.) Turn the adapter off the stud. Hold the stud with a wrench and continue turning until the clutch plate assembly is pressed onto the shaft and woodruff key, making certain that the clutch cover ring does not get caught between the coil housing and the rear clutch plate. Remove the assembly tool.

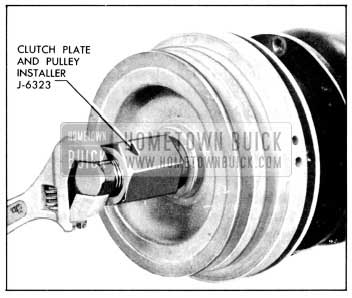

- Replace the clutch hub and pulley bearing washer and shims on the compressor shaft, observing instructions in step 4 to obtain proper clutch clearance.

1956 Buick Installing Pulley

Removal and Installation of Clutch Coil and Shaft Seal

- Following instructions contained in preceeding steps 1 through 9 remove pulley and clutch.

- Disconnect the electrical leads of the coil from the terminal clip and ground screw.

- Remove the three coil retaining screws from the seal and coil housing.

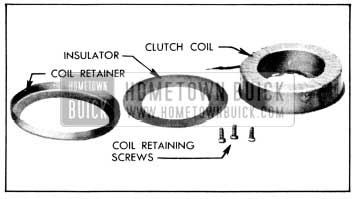

1956 Buick Clutch Coil Disassembled

The service replacement shaft seal assembly is supplied in a unit package. It contains the shaft seal, and seal seat, pin and retainer ring, and „O“ rings and auxiliary shaft seal, wiping tissues and packing list.

The old „O“ rings removed from the compressor should be discarded and replaced with the fresh ones contained in the unit package.

The shaft seal having the carbon block face and the polished metal seal seat should be handled very carefully to avoid damage to the fine finishes on their surfaces. When the seal seat retainer ring is replaced, use care not to scratch or mar the polished surface. Even when the seal surfaces are coated with oil, use care not to contact the seal surfaces with any metallic object, such as tip of oil can, rod, screw driver etc.

The lint-free tissues included in the replacement unit package should be used for the final cleaning of the shaft, seal cavity and parts. The seal cavity in the coil housing and around the auxiliary seal should be flooded with clean, fresh Frigidaire 525 viscosity oil prior to assembly. This oil should be taken out of the glass container, in which it is supplied. It is the same oil that is used in the compressor. No other oil should be used for this purpose. Coat all „O“ rings, seal :faces and parts with this oil.

1956 Buick Secondary Shaft Seal and Protector

The shaft seal has an „O“ ring on the inside of it and will contact the O.D. of the compressor shaft when assembled. It must be protected when it is being placed over the shaft. To do this, place the shaft „O“ ring pilot bushing, J-6320, over the shaft against the second step. Apply a light coating of oil to the surface before sliding the seal and „O“ ring in place.

The auxiliary seal has a coating on the outer surface to effect a seal with the coil and seal housing when it is pressed into the coil housing. The inner flexible seal has a “V” shaped edge and is provided with a ring-shaped spring to apply the necessary sealing pressure to the shaft.

The inner lip of the auxiliary seal should be given a heavy coating of Frigidaire compressor oil and the space between the seal seat and the auxiliary seal in the coil housing should be flooded with the same oil.

Assemble the special pilot bushing, J-6320, into the auxiliary seal before assembling the coil and seal housing over the compressor shaft and to the compressor flange. Use care during this operation and also when removing the pilot bushing so as not to disturb the spring behind the “V” lip of the auxiliary seal. The inner lip of the auxiliary seal should be given a heavy coating of oil prior to assembly into the housing. Carefully slide housing over shaft to compressor body making certain that the small oil drain-back passage „O“ ring is not dislodged.

After the housing has been placed over the shaft and the „O“ ring end assembled to the compressor flange, install the six mounting screws.

The compressor seal should now be given a Freon-12 leak test to be sure the assembly has been properly made and is leak-tight prior to reassembly on the car.

It is suggested that a bar of metal similar to the service compressor shipping plate be made up for a cover plate over the suction discharge opening. Drill and tap plate in the area that will cover the suction or low pressure opening for either 1/8″ or 1/4″ pipe thread and screw in a 1/8″ pipe to a 1/4″ flare or 1/4″ pipe to 1/4″ flare fitting and use two „O“ rings and the plate mounting bolt to seal the opening.

Connect a drum of Freon-12 to the fitting with a charging hose or copper line, which will pressurize the interior of the compressor and the compressor shaft seal. Leak test with leak detecting torch, around the shaft, seal, auxiliary seal and large diameter „O“ ring in the seal housing and the compressor flange.

Correct any leaks that may be found and proceed with reassembly of parts.

Assemble the inner insulator, actuating coil, outer insulator, coil retainer and the three screws in the coil housing.

The coil leads should be sealed with the sealing compound that was removed from the opening in the coil-seal housing.

1956 Buick Clutch and Seal Exploded View

The compressor is now ready to be replaced on the engine mounting brackets. Connect the suction-discharge valve assembly to the compressor using new „O“ rings from stock.

Proceed to evacuate or purge the air from the compressor, in accordance with previous service instructions.

Operate the engine and air conditioning system and check operation.

Position the valves on the compressor properly for normal operation. Cap the test gauge fittings and replace the caps on the valve stem end, making certain the copper gaskets are in place.

Servicing the Compressor on the Car

- Preparation for Removing Compressor Shaft Seal.

- With engine at low idle (450 RPM) and gauge set attached, close low pressure compressor shut-off (service) valve and energize clutch coil (turn unit on).

- When low gauge reading reaches “0” turn engine and air conditioner switches off and close high pressure compressor shut-off (service) valve.

- Loosen generator mounting bolts to relax belts; then remove belts from compressor pulley.

- Preparation for Removing Compressor Clutch Only.

When just the pulley and clutch and/or clutch coil are to be removed, only step c of the preceding section need be observed.

Adding Oil to Compressor and Checking Oil Level

A stud fitting is welded into the compressor shell at the forward end, just behind mounting ring. The fitting is placed 43 degrees to the side of the vertical centerline. It is threaded on the inside to receive a screw that has a hole drilled in the center. Another hole is drilled at right angles to the center hole, and is just under the screw head. A copper gasket is used to seal the head to the stud.

The end of the stud and screw project through the shell and the opening into the screw is at the 4 ounce oil level.

The production compressor was originally charged with either 9 ounces or 12 ounces of 525 viscosity Frigidaire oil.

If an unknown quantity of oil has been lost through accident, or a leak of Freon and oil at any of the fittings has occurred, it is advisable to check the oil supply in the compressor.

Operate the engine at slow idle for 5 to 7 minutes with the air conditioning system turned on and the blower operating in High. Stop the engine and compressor.

Loosen the screw in the oil test fitting and allow a slight seepage of oil to escape. Then retighten the screw for a moment, then “crack” open slightly again. If a steady flow of oil is evident, the oil level is either at the safe minimum level of 4 ounces, or the compressor contains oil in excess of this, and could be a full oil charge up to either 9 or 12 ounces.

NOTE: A service re placement compressor contains 9 ounces of 525 viscosity oil.

When the oil test screw was “cracked” open the second time and there was no oil escaping or a hissing or vapor only was evident, this indicates that the oil is below the safe minimum level and oil should be added to the compressor as per following instructions.

Attach a gauge set to the proper connections on the compressor. Follow previous instructions on precautions about purging air from all gauge lines, prior to operating the engine and compressor. Close the low pressure valve on the compressor.

Operate the engine at a slow idle until 10 to 20 inches of vacuum is obtained. Connect a charging line and copper tube to the center connection on the gauge manifold and insert the copper tube to the bottom of the oil bottle.

Slowly open the hand shutoff valve on the gauge manifold. This will permit high pressure vapor to purge the air from the charging line and copper tube and bubble it slowly through the oil. Close hand shutoff valve on gauge manifold and also close the high pressure valve on the compressor.

Open the low side hand shutoff on the gauge manifold. This will cause the oil in the bottle to be drawn into the low side of the compressor. Add oil in two ounce increments until sufficient oil has been added to the compressor to produce a satisfactory level when checked at the test screw.

11-9 EVACUATION AND CHARGING

Evacuation of System with Vacuum Pump

- Attach gauge lines and vacuum pump set-up as shown in figure 11-35.

1956 Buick Service Charging Hook-up

CAUTION: The foregoing steps for hooking up gauge lines should be followed whenever evacuating or charging the system. Firmly back-seating the (service) shut-off valves (First Par.) will prevent escape of Freon when the smaller protective caps are removed from the rear end of compressor.

Evacuation of System without Vacuum Pump

In cases where is becomes necessary to evacuate the Air Conditioner and it is impossible to obtain the proper pump for this evacuation, the following procedure may be followed.

- Hook up gauges, lines and Freon 12 Cylinder as shown in Figure 11-35, but substitute a bottle or other suitable container in place of the vacuum pump. The container is to catch the evacuated oil so it may be measured and a like amount of clean oil replaced. Be sure that the fitting on the discharge valve is open to the compressor with no restrictions from valve closures, caps, or plugs in the attached line before starting the engine.

- Leaving low pressure gauge valve tightly closed, carefully open the high pressure gauge valve and hand shut-off valve (vacuum line valve), being careful to avoid any accidental discharge of liquid Freon 12. Discharge Freon, air, and any oil into bottle.

- Start engine and set at low idle (450 rpm) and turn Air Conditioner Blower switch on “Hi” and “Max. cooling”. Maintain engine speed at slow idle at all times during evacuation. Close high pressure compressor service valve (turn all the way clockwise).

- Operate system at low idle for 5 minutes then turn off engine and air conditioner and close hand shut-off valve immediately. If system holds 25″ vacuum for 10 minutes, proceed to Step 5; if not, locate and correct leak and repeat steps 2, 3 and 4.

- Close high pressure gauge valve, open low pressure gauge valve, and charge system with Freon at cylinder pressure. Then evacuate again as in steps 1, 2, 3, and 4 for 5 minutes.

- Again close high pressure gauge valve, and open low pressure gauge valve and then complete charging with 5 1/2 lbs. of Freon.

- Following the procedure outlined, replace an amount of clean (Frigidaire 525 viscosity) compressor oil equal to that discharged in steps 4 and 5. Then perform oil level check.

- Remove gauge lines and oil charging lines, cap the fittings, and check the performance of the unit.

CAUTION: Under no circumstance s should it be assumed that the fore going procedure will remove water from the system. Where a leak has occurred and there is a possibility that the system has been operated in a discharged condition, it is essential that the dehydrator be changed.

Charging the System

With the vacuum pump, Freon-12 cylinder and gauge set connected to the compressor as shown in Figure 11-35 and 12, place the cylinder in a bucket of hot water which does not exceed 125° F.

CAUTION: Do not heat Freon-12 cylinder above 125° F. because the fusible safety plug in cylinder valve melt s at 157° F and softens at a slightly lower temperature.

- Place cylinder and bucket on a suitable scale and record the total weight.

- Open the low pressure valve on the gauge set. (High pressure valve on gauge set closed.)

- Wearing goggles to protect eyes, fully open the Freon-12 cylinder valve and allow Freon-12 vapor to flow into the refrigerating system.

- Operate engine and compressor at slow idling speed until a total of 5 1/2 pounds of Freon-12 have been charged into the system.

NOTE: It may be necessary to reheat the water in bucket to maintain required pressure.

- Close both valves on gauge set, close valve on Freon-12 cylinder, and remove cylinder from bucket of water.

- Operate the compressor with engine running at 1750 RPM (using tachometer) and observe general performance of Air Conditioner. If performance is satisfactory, stop the engine.

- With engine off, firmly back-seat both high and low shut-off (service) valves on compressor, then remove gauge lines.

- Replace protective caps over gauge connectors and shut-off valves, then tighten securely.

- Check oil level in compressor as described in paragraph 11-8 (d).

11-10 FUNCTIONAL TEST

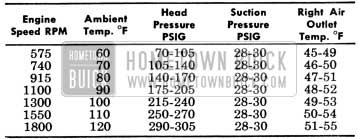

Test Conditions: Hood closed, doors open, heater Ranco valve off, Air Conditioner controls set for “Max” cooling and no sun load.

NOTE: Set Engine Speed as designated for each corresponding ambient temperature.

1956 Buick Engine Speed with Outlet Temperatures

1956 Buick Clutch Coil Wiring Diagram

Leave A Comment

You must be logged in to post a comment.