SECTION 7-C 1956 BUICK CHASSIS SUSPENSION SERVICE, ADJUSTMENT, AND REPLACEMENT PROCEDURES

7-8 1956 BUICK TIRE SERVICE AND INSPECTION

1956 Buick Tire Inflation and Inspection

Maintenance of correct inflation pressure in all tires is one of the most important elements of tire care. Correct tire pressure is also of great importance to ease of handling and riding comfort. Overinflation is detrimental to tire life but not so much as underinflation. Inflate all tires according to tire temperature as specified in paragraph 1-1.

Driving without valve caps contributes to underinflated tires. The valve cap keeps dirt and water out of the valve core and seals the valve against leakage. Whenever tires are inflated be sure to install valve caps and tighten firmly by hand. Make sure that rubber washer in cap is not damaged or missing.

If tires are checked at frequent intervals and adjusted to correct inflation pressure, it is often possible to detect punctures and make a correction before a tire goes flat, which may severely damage tire and tube if car is in motion. Slight differences in pressure between tires will always be found, but a tire that is found to be 3 or more pounds below the lowest of its running mates can be suspected of having a leaking valve or a puncture.

All tires should be inspected regularly to avoid abnormal deterioration from preventable causes. If tires show abnormal or uneven wear the cause should be determined and correction should be made.

See that no metal or other foreign material is embedded in the tread. Any such material should be removed to prevent damage to tread and tire carcass. Cuts in a tire which are deep enough to expose the cords will allow dirt and moisture to work into the carcass and ruin the tire unless promptly repaired.

Tubeless Tire Repairs

A leak in a tubeless tire may be located by inflating the tire to recommended pressure (par. 1-1) and then submerging tire and wheel assembly in water, or by applying water to tire with a hose if wheel is mounted on car. Remove water from area where air bubbles show and mark the area with crayon. After removal of the puncturing object from tire, the puncture must be sealed to prevent entrance of dirt and water which would cause damage to the tire carcass.

A small puncture of less than 3/32″ diameter may be sealed without removal of tire from wheel by injecting sealing dough with a gun. Punctures up to %,”diameter may be sealed by installation of a rubber plug with cement, after tire has been removed from wheel. Sealing dough with gun, and rubber plugs with cement are contained in tire repair kits available through tire dealers. These materials should be used as directed in the instructions supplied with the kits. If a puncture is larger than 14,” or there is other damage to the tire carcass, repairs should be made by authorized tire dealers in accordance with instructions of the tire manufacturer.

Demounting and Mounting of Tubeless Tire

When demounting a tubeless tire use care to avoid damaging the rim-seal ridges on tire beads. A “bead breaker” is recommended for loosening the beads. DO NOT USE TIRE IRONS TO FORCE BEADS AWAY FROM WHEEL RIM FLANGES. After both beads are broken loose from wheel rim flanges, remove tire in usual manner, starting at the valve stem, and using care to avoid damaging rim seal ridges.

When tire is removed, inspect it carefully to determine whether loss of air was caused by puncture or by improper fit of beads against rim flanges. If improper fit is indicated, check wheel as follows:

- Straighten wheel rim flanges if bent or dented.

- Clean rims thoroughly, using No. 3 coarse steel wool, to remove all oxidized rubber, soap solution, etc. Remove rust with wire brush.

- Inspect butt weld and other areas of rim contacted by tire beads, to make certain there is no groove or high spot. Remove any groove or high spot by filing smooth.

- Inspect valve stem and replace it if damaged. Make certain that valve stem is properly installed to provide an air tight joint.

Before mounting a tubeless tire on a wheel remove cardboard spacer, if tire is new. Moisten a cloth with clean water (no soap solution or solvent) and wipe rim-seal ridges of both beads to remove all foreign substance. Moisten base of both beads with clear water (no soap solution) to help beads snap into place when tire is inflated. Start tire over rim flange at point diametrically opposite valve stem, so that valve stem cannot prevent bead from dropping into the well as last section of bead is forced over the rim flange. Align balance mark on tire with valve stem.

Either a tire mounting machine or tire irons may be used; however, parts of tools contacting tire beads must be smooth and clean to avoid damaging rim-seal ridges. Take small bites if tire irons are used. DO NOT USE HAMMERS.

Remove valve core to increase flow of air during inflation. Hold tire and wheel assembly in vertical position and bounce on floor at various points around circumference to snap beads out against rim flanges. If a seal cannot be effected in the foregoing manner with the rush of air, apply a tourniquet of heavy sash cord around circumference to tire and tighten it with a tire iron to force beads outward.

Inflate tire until both beads are firmly seated against rim flanges, then remove air chuck, insert valve core and temporarily inflate to 50 pounds pressure. Leak test wheel and tire assembly under water, and if satisfactory reduce to recommended pressure (par. 1-1).

Interchanging Tires – 1956 Buick

Tires tend to wear unevenly and become unbalanced as mileage accumulates. Uneven tire wear is frequently the cause of tire noises which are attributed to rear axle gears, bearings, etc., and work is sometimes needlessly done on rear axles in an endeavor to correct the noise.

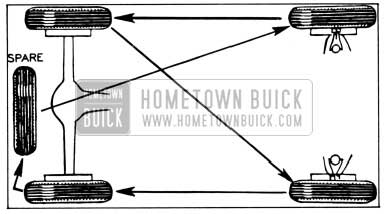

Tire life will be increased and uneven wear and noise will be less likely to occur if the tires, including the spare, are balanced and interchanged at regular intervals of approximately 5000 miles. The recommended method of interchanging tires is shown in figure 7-7.

1956 Buick Method of Interchanging Tires

Use of Tire Chains on a 1956 Buick

Do not use tire chains on the front wheels under any circumstances because they will interfere with the steering mechanism. Any of the conventional full-type non-skid tire chains can be used on the rear wheels.

Tire chains should be loose enough to “creep” but tight enough to avoid striking fenders or other parts. If chains remain in one position the tire side wall will be damaged. Tension springs (either metal coil springs or the rubber band type) must also be used in order to prevent chains contacting frame, etc. The use of tension springs will also reduce ordinary chain noise caused by loose cross links contacting pavement.

7-9 REPLACE AND ADJUST STABILIZER LINK GROMMETS

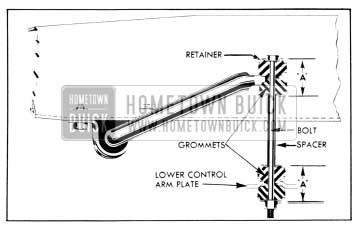

The construction of the stabilizer links is clearly shown in figure 7-8.

1956 Buick Front Stabilizer Link-Sectional View

To disassemble, remove nut from lower end of the link rod, then remove rod, spacer, retainers, and grommets. When new, the link grommets are 7/8″ free length. When assembling, install rubber grommets dry and use care to center the grommets in the seats on stabilizer shaft and lower control arm plate, also center the retainers on grommets before tightening rod nut. Tighten rod nut to the limit of thread on rod.

When the rod nut is tightened to limit of threads on rod, the overall dimension between sides of grommet retainers as shown at “A” in figure 7-8 should be 1 11/16″. If dimension “A” is not 1 11/16″ when nut is tight, adjust the nut to obtain this dimension. This is important to insure proper riding qualities and stabilization.

7-10 REPLACE AND ADJUST 1956 BUICK FRONT WHEEL BEARINGS

Replacement of Bearings

- Remove wheel with hub and drum assembly. Remove oil seal packing from hub so that inner bearing can be properly cleaned and inspected.

- Wipe old grease out of hub and from steering knuckle spindle. Clean and inspect all bearing parts as described under Bearing Service (par. 1-10), and replace any that are faulty.

- If a bearing cup has to be replaced, drive the old cap out with a punch. Use care when installing the new cap to start it squarely into hub, to avoid distortion and possible cracking.

- When inspecting or replacing bearing cones (inner races) make sure that cones are free to creep on spindle of steering knuckle. The cones are designed to creep on the spindle in order to afford a constantly changing load contact between the cones and the ball bearings. Polishing the spindle and applying bearing lubricant will permit creeping and prevent rust forming between cone and spindle.

- Wash and thoroughly dry all bearing parts, because wheel bearing lubricant will not adhere to oily surfaces.

- Thoroughly pack both ball bearing assemblies with new wheel bearing lubricant, preferably using a bearing packer. If packer is not available, work lubricant into bearings by hand. In either case, remove any surplus lubricant.

- Apply a light coating of lubricant to spindle and inside surface of wheel hub to prevent rusting.

- Place inner bearing assembly in cup and install a new oil seal, driving seal squarely into hub to avoid distortion. Carefully install inner bearing cone in oil seal. NOTE: Never place cone on spindle because seal will be damaged as wheel is installed.

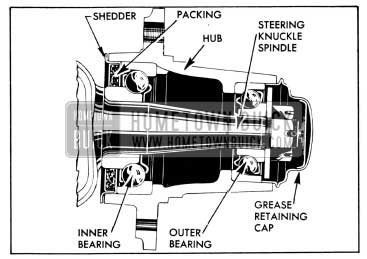

- Install wheel on spindle, then install outer bearing assembly, cone, safety washer and nut. See figure 7-9.

1956 Buick Front Wheel Hub and Bearings

Adjustment of 1956 Buick Front Wheel Bearings

- Tighten spindle nut with 10″ wrench until bearings are preloaded at least one hex, then rotate wheel one revolution to make sure bearings are seated.

- Back off spindle nut until bearings are slightly loose. Tighten nut until all bearing looseness is just removed, then line up nut to nearest cotter hole and install cotter pin. Do not mistake loose king pin bushing, etc., for wheel bearing looseness. CAUTION: Bearing preload must not exceed lj12 turn of spindle nut.

- Before installation of grease cap in hub, make sure that end of spindle and inside of cap are free of grease so that radio static collector makes a good clear contact. Make sure that static collector is properly shaped to provide good contact between end of spindle and the grease cap.

7-11 REMOVE AND INSTALL 1956 BUICK STEERING KNUCKLE

- Remove front wheel with hub and drum assembly.

- Remove brake backing plate and steering arm from steering knuckle. Do not disconnect brake hose but support backing plate out of way to avoid strain on hose.

- Drive out king pin lock pin.

- Remove upper welsh plug from knuckle by piercing with a sharp pointed punch and prying out.

- Drive king pin down and out, which will drive lower welsh plug from knuckle. Remove thrust bearing and shims.

- Install steering knuckle by reversing the removal procedure. Use shims as required between the knuckle support and upper boss of steering knuckle to provide .003″ end play of knuckle on the support. Use new expansion plugs at both ends of king pin.

- Lubricate and adjust front wheel bearings as described in paragraph 7-10.

- Check and adjust caster, camber, and toe in (par. 7-17). Be sure to install grease fitting in pivot pin bushing.

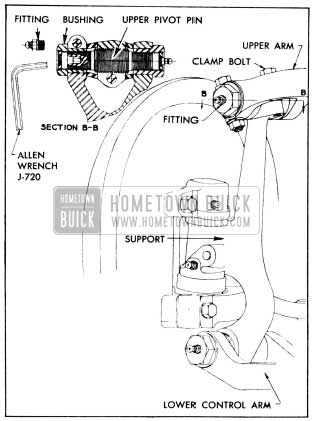

7-12 REMOVE AND INSTALL PIVOT PIN, BUSHINGS, SHAFT IN SUPPORT UPPER ARM

Removal of Bushings and Pivot Pin

- Place jack under lower control arm, raise wheel off floor, and remove wheel and tire assembly.

- Remove pivot pin bushing clamp bolt in support upper arm, then remove both pivot pin bushings from upper arm, and remove rubber seals.

- Loosen clamp bolt in knuckle support and remove pivot pin, using 14″ hex Allen wrench. NOTE: Tie steering knuckle support to upper arm to prevent damage to b rake hose.

Installation of Pivot Pin and Bushings

- Hold knuckle support in line with hole through support upper arm and screw pivot pin into knuckle support, with adjusting wrench hole in pin toward the split side of control arm.

- Turn pivot pin until the large diameter section is centralized in knuckle support and tighten the clamp bolt. Install rubber seals on both ends of pivot pin.

- Centralize knuckle support boss in support upper arm yoke and start the externally threaded bushing on threads of pivot pin and into threads of control arm.

- Start the plain (grooved) bushing on threads of pivot pin, then turn the opposite bushing up tight. Turn the plain bushing up until hex is just clear of arm, then install and tighten clamp bolts.

- Check and adjust caster, camber, and toe-in (par. 7-17). Be sure to install grease fitting in upper pivot pin bushing.

Remove and Install Support Upper Arm and Shaft

If a support upper arm is bent or broken, use a new arm assembly which includes the shaft, bushings, and dirt seals. If only the shaft and bushings require replacement use the following complete procedure.

- Remove generator and engine front mounting nuts, then raise engine just enough to allow removal of support upper arm shaft bolts.

- Remove pivot pin and bushings (subpar. a, above), then remove shaft attaching bolts and remove arm assembly from car.

- Unscrew shaft bushings and remove shaft and seals from upper arm.

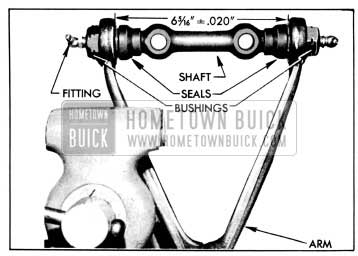

- Before installing any new parts, check the distance between inner ends of the upper arms. The normal dimension is 6 5/16″ +/- .020″. See figure 7-10.

1956 Buick Upper Arm, Shaft, Bushings and Seals

7-13 CHECKING AND REPLACING 1956 BUICK CHASSIS SPRINGS

Checking 1956 Buick Spring Trim Dimensions

Optional equipment, undercoating, etc., changes the car weight and must be considered when checking 1956 Buick spring trim dimensions. Because of the many possible variations in loading due to optional equipment it is not possible to give dimensions for all; therefore, the spring trim dimensions given below are for the standard car only, without optional equipment or undercoating and with car at curb weight. Curb weight includes gas, oil, water, and spare tire but no passengers.

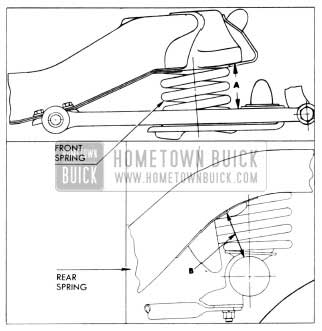

Before measuring spring trim dimensions, bounce both ends of car up and down several times to make sure there is no bind in suspension members, and to let springs take a natural position. When car is at rest, measure the trim height at point “A” for front spring or point “B” for rear spring, as indicated in figure 7-11.

1956 Buick Spring Trim Dimensions

- Front Springs. On a car having service miles the front spring trim dimension “A” should be within the following limits, with CM at curb weight.

Model – “A”

46C, 56C, 76C – 3 1/2” – 4”

All other models – 3 3/4 – 4 1/4”

NOTE: When checking NEW car add 1/4”

When the trim dimension is found to be too low, correction may be made by installing special shims (Group 7.425), 1/8″ thick, between upper end of spring and the frame. If more than three shims are required, replace the spring.

- Rear Springs. On a car having service miles the rear spring trim dimension should be within the following limits, with car at curb weight.

Model – “B”

46C, 46R, 56C, 56R, 66C, 66R, 76C, 76R – 4 1/4” – 5 1/4”

All other models – 5 1/2” – 6 1/4”

NOTE: When checking NEW car add 3/8″

If trim dimension is less than specified or additional height is required to prevent excessive “bottoming” in exceptional cases, install additional spring insulators (group 7.545), divided between upper and lower ends of spring. If more than three additional shims are required replace the spring. Installation of new springs should not increase spring trim dimension “A” more than 1″ over specified maximum limit.

Removal and Installation of 1956 Buick Front Spring

- Place jack under lower control arm, raise wheel off floor, and remove wheel and tire assembly.

- Disconnect stabilizer link from lower control arm and disconnect outer end of the tie rod from steering arm.

- Remove 1956 Buick shock absorber (par. 7-15).

- Remove lower pivot pin nut, pivot pin, lockwasher, and dirt seals.

- Support car frame by another jack, then slowly lower the jack under lower control arm. This will allow lower control arm to drop low enough to remove chassis spring.

- Before installation of front spring, check the part number which is stamped on one end coil to make sure that spring is correct for the car model, as specified in Group 7.412 of Master Parts List.

- Make sure that the rubberized fabric spring insulator is in place around the spring centering flange on frame and is in good condition.

- Place one end of spring over the centering flange, and as lower control arm is raised, position lower end of spring so that the end coil seats in the recess provided in spring seat. Support lower control arm on a jack.

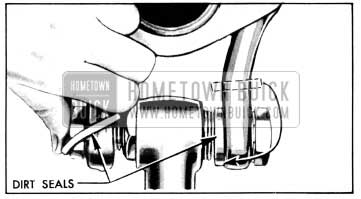

- Slip the lower pivot pin dirt seals over outer ends of lower control arm. Centralize lower end of knuckle support between outer ends of lower control arm, then install lower pivot pin and lockwasher from front side and tighten securely. Install and tighten nut. Snap dirt seals into place over pivot pin. See figure 7-12.

1956 Buick Installing Dirt Seals

Removal and Installation of 1956 Buick Rear Spring

- Disconnect both rear shock absorber lower ends.

- Hoist rear end of car until all load is off rear springs and place floor stands under frame for safety.

- Remove spring clamps at lower and upper ends and remove spring.

- Check part number stamped on one end coil of new spring to make certain that spring is correct for the car model as specified in Group 7.503 of Master Parts List.

- Be sure that spring insulator in upper seat is in good condition then attach upper end of spring using spring clamp, bolt insulator, flat washer, lockwasher and bolt in the order named. Attach lower end of spring with spring clamp, lockwasher and nut.

- Lower rear end of car and attach lower ends of shock absorbers. NOTE: Car weight must be on rear wheels when tightening shock absorber ends to clamp rubber bushings in a neutral position.

Use of Special Overload Rear Springs

Special 500 pound overload rear springs are available for service installation in cases where heavy loads are carried or heavy trailers are towed. Overloading any series rear axle in excess of 500 pounds is not recommended.

In estimating rear spring overloads, place rear wheels of car on scale, with car at curb weight and no load in rear compartment other than spare wheel and tire. After obtaining weight, hook trailer to car, or place desired load in rear compartment, and read scale again. The additional weight is the amount of overload on springs and rear axle.

Trailer design, and distance that trailer coupling is located to rear of rear axle center line, are the major factors governing effective trailer overload. Instructions for attaching trailers to Buick cars may be obtained from Buick Motor Division Factory Service Department.

7-14 REPLACE OR REBUSH 1956 BUICK LOWER CONTROL ARM ASSEMBLY

If a 1956 Buick lower control arm is bent or broken it should be replaced with a new assembly which includes the shaft, bushings, and dirt seals. The riveted parts of the assembly are not furnished separately. If only the shaft and bushings require replacement these can be obtained separately.

Use all of the following steps for replacement of control arm shaft and bushings. Use only steps 1, 9 and 10 for replacement of control arm and shaft assembly.

- Remove 1956 Buick front chassis spring (par. 7-13) then remove lower control arm assembly from frame front cross member.

- Unscrew bushings and remove shaft from control arm.

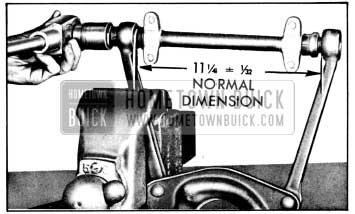

- Check the distance between inner ends of control arm. The normal dimension is 11 1/4″ plus or minus 1/32″, from inside to inside. See figure 7-14.

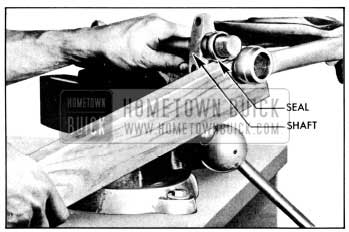

- Install a rubber seal over each threaded end of new control arm shaft, with the large or bell ends of seals outward toward ends of shafts.

- Insert one end of shaft with the seal in place in one control arm end and force opposite end of shaft into the other control arm end. A piece of wood approximately 1 1/4″x2 1/2″x24″ long can be used as a pry. See figure 7-13.

1956 Buick Springing Arm Over End of Shaft

NOTE: Apply a liberal amount of white lead or Lubriplate to both bushings before installing in arms.

- Start first bushing on shaft and into control arm at the same time. Turn bushing until head is tight against arm and tighten to a minimum of 150ft. lbs. torque. See figure 7-14.

1956 Buick Installing First Bushing

7-1 5 1956 BUICK SHOCK ABSORBER SERVICE AND REPLACEMENT

Checking Shock Absorbers

Both front and rear shock absorbers are filled and sealed in production and cannot be refilled in service.

Removal and Installation of 1956 Buick Front Shock Absorber

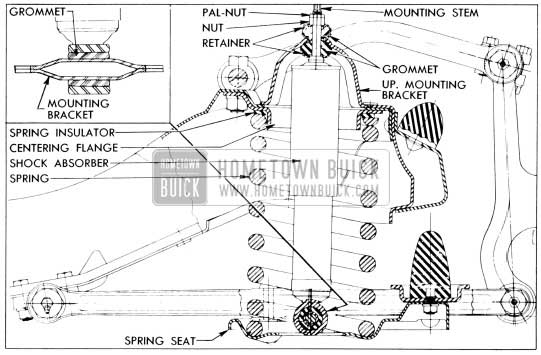

- Hold shock absorber mounting stem with a 1/4″ end wrench while removing pal-nut and retaining nut, then remove grommet retainer and rubber grommet. See figure 7-15.

1956 Buick Front Spring and Shock Absorber Installation

Removal and Replacement of 1956 Buick Rear Shock Absorber

- Remove lower shock absorber mounting eye bolt, nut, washer, spacer and rubber bushings.

- Remove upper shock absorber mounting eye bolt, nut, spacer and rubber bushings. Remove shock absorber.

- Inspect all rubber bushings and replace if not in good condition. If shock absorber operation is faulty, it must be replaced as it cannot be repaired.

- Make certain that new shock absorber is correct for car model as indicated by code and part numbers stamped on the outer tube. See paragraph 7-1 and Master Parts List Group 7.345.

- Place spacers and rubber bushings in shock absorber mounting eyes. Hold shock absorber in position and install pivot bolts and nuts.

- Lower rear end of car. Then tighten pivot bolts until brackets are tight against ends of spacer. NOTE: Car weight must be on rear wheels when tightening shock absorber ends to clamp rubber bushings in a neutral position.

Shock absorber calibrations as furnished in production, and as given in 1956 Buick Chassis Suspension Specifications (par. 7-1) have been carefully engineered to provide the best ride control over a wide range of driving conditions. Substitution of other calibrations should not be attempted under any circumstances, unless authorized by Buick Motor Division.

7-16 1956 BUICK WHEEL AND TIRE BALANCE

Wheel and tire balance is the equal distribution of the weight of the wheel and tire assembly around the axis of rotation. Wheel unbalance is the principal cause of tramp and general car shake and roughness, and contributes somewhat to steering troubles.

All 1956 Buick wheel and tire assemblies are balanced when assembled at the factory. After installation of tire on the wheel, the assembly is further corrected for balance, if necessary, by installing balance weights on the rim of the wheel.

The original balance of the tire and wheel assembly may change as the tire wears. Severe acceleration, severe brake applications, fast cornering and side slip wear the tires out in spots and often upset the original balance condition and make it desirable to rebalance the tire and wheel as an assembly. Tire and wheel assemblies should be rebalanced after punctures are repaired.

Because of the speed at which cars are driven it is important to test the wheel and tire assembly for dynamic balance. Dynamic balancing of a wheel and tire assembly must be done on a machine designed to indicate out of balance conditions while the wheel is rotating. Since procedures differ with different machines, the instructions of the equipment manufacturer must be carefully followed.

In some cases wheel and tire balance does not always overcome wheel balance complaints because the brake drums themselves are out of balance. Balancing drums with wheels and tires as an assembly is not always satisfactory because the balance is destroyed when wheels and tires are removed or interchanged. On cars where trouble is experienced in maintaining proper wheel balance, it is suggested that all drums be individually checked for static balance and corrected, if necessary, as described under 1956 Buick Brake Drum Balance (par. 9-12).

7-17 1956 BUICK FRONT WHEEL ALIGNMENT

Wheel alignment is the mechanics of properly adjusting all the factors affecting the position of front wheels so as to cause the car to steer with the least effort and to reduce tire wear to a minimum.

Correct alignment of the 1956 Buick frame is essential to proper alignment of front and rear wheels. Briefly, the essentials are that the frame must be square in plan view within specified limits, that the top and bottom surfaces of front cross member must be parallel fore and aft, and the bolt holes for support upper arms and lower control arm shafts must be of correct size and location. Checking frame alignment is covered in Group 12.

It should also be understood that wheel and tire balance has an important effect on steering and tire wear. If wheels and tires are out of balance, “shimmy” or “tramp” may develop or tires may wear unevenly, and give the erroneous impression that the wheels are not in proper alignment. For this reason, the wheel and tire assemblies should be known to be in proper balance before assuming that wheels are out of alignment.

Close limits on caster, front wheel camber, and king pin inclination are beneficial to ease of steering, but require only reasonable accuracy to provide normal tire life. With the type of front suspension used, the toe-in adjustment is much more important than caster and camber in so far as tire wear is concerned. Caster and camber adjustments need not be considered unless visual inspection shows these settings to be out, or unless the car gives poor handling on the road.

In the majority of cases, services consisting of inflating tires to specified pressure and interchanging tires at recommended intervals (par. 7-8), balancing all wheels and tires (par. 7-16) adjusting steering gear (par. 8-4), and setting toe-in correctly (subpar. e, below) will provide more improvement in car handling and tire wear than will front end alignment adjustments as usually made on front end alignment equipment.

The use of accurate front end alignment is essential to determine whether front suspension parts have been damaged by shock or accident, and to obtain correct alignment settings after new parts have been installed.

Inspection Before Checking 1956 Buick Front Wheel Alignment

Before any attempt is made to check or make any adjustment affecting caster, camber, toe-in, king pin inclination, or steering geometry, the following checks and inspections must be made to insure correctness of alignment equipment readings and alignment adjustments.

- The front tires should have approximately the same wear and all tires must be inflated to specified pressures (par. 1-1).

- Check front wheel bearings for looseness and adjust, if necessary (par. 7-10).

- Check for run-out of wheels and tires and correct to within limit of 1/8″ run-out at side of tires, if necessary.

- Check wheels and tires for balance and correct if out of balance (par. 7-16).

- Check for looseness at king pins and tie rod ends; if found excessive it must be corrected before alignment readings will have any value.

- Check shock absorber action and correct, if necessary (par. 7-5).

- Car must be on a level surface and at curb weight (no passengers, no load in car, spare tires in place, and full of water, oil, and gasoline).

- Bounce car at front and rear ends several times to allow frame to come to its normal level. Check spring trim dimensions and make any correction indicated (par. 7-13).

- It is also advisable to check the condition and accuracy of any equipment being used to check front end alignment, and to make certain that instructions of the manufacturer are thoroughly understood.

Checking Caster and Camber Settings

Since caster and camber are both adjusted by turning the eccentric knuckle support upper pivot pin, both of these settings must be checked before changing either setting.

CAUTION: Regardless of equipment used to check caster and camber-, car must be on level surface both transversely and fore and aft, and must be at curb weight. Since camber varies in proportion to the height of the front springs, it is very important that the correct spring trim dimension is maintained while checking camber (par. 7-13).

When equipment is used which bears against the tire or wheel rim to obtain readings, it is very essential that the tires or wheels be checked for run-out. Readings must be taken at points which have no run-out or which lie in the same plane.

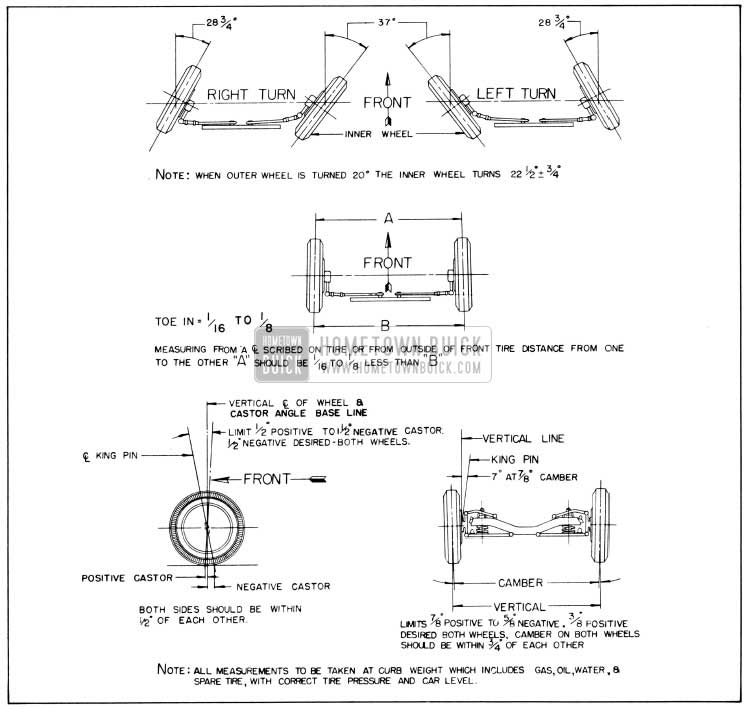

Caster and camber should be within the limits shown in figure 7-16. Note that the caster angles at both front wheels need not be exactly the same but must be within 1/2 degree of each other. Likewise, the camber angles on both sides must be within 3/4 degrees of each other.

1956 Buick Front Wheel Alignment Specification Chart

If caster and camber are not within the specified limits, adjust as described below.

Adjustment of Caster and Camber

Caster and camber must be adjusted together to obtain the best average setting of each within the specified limits given in figure 7-16.

- Loosen pivot pin clamp bolt on upper end of knuckle support. Remove grease fitting from the clamped type upper pivot pin bushing. This bushing is on front end of the right pivot pin and on rear end of left pivot pin. See figure 7-17.

1956 Buick Steering Knuckle Support and Pivot Pins Illustration

Checking King Pin Inclination

CAUTION: When checking king pin inclination, car must be on a level surface, both transversely and fore and aft. It must be at curb weight and must be maintained at specified spring trim height while checking (par. 7-13).

With camber known to be within specified limits, king pin inclination should check within specified limits given in figure 7-16.

If camber is correct and king pin inclination is not correct, a bent steering knuckle support is indicated.

If camber is incorrect beyond limits of adjustment and king pin inclination is correct, or nearly so, a bent steering knuckle is indicated.

If camber and king pin inclination are both incorrect by approximately the same amounts, a bent upper or lower control arm is indicated.

There is no adjustment for king pin inclination as this factor depends upon the accuracy of the front suspension parts. Distorted parts should be replaced with new parts. The practice of heating and bending front suspension parts to correct errors is not recommended as this may produce soft spots in the metal in which fatigue and breakage may develop in service.

Checking and Adjusting Toe-In

CAUTION: Car must be at curb weight and specified trim height, with steering gear and front wheel bearings properly adjusted and no looseness at tie rod ends. See subparagraph a, above. The car should be moved forward one complete revolution of the wheels before the toe-in check and adjustment is started and the car should never be moved backward while making the check and adjustment.

- Turn steering wheel until lower spoke is vertical, with front wheels in straight ahead position.

- Measure the horizontal distance from the near edge of front boss of lower control arm shaft to the front edge of brake backing plate, on each side. Adjust tie rods, if necessary, to make measurements equal on both sides.

- Using a suitable toe-in gauge, measure the distance between outside walls of tires at the front at approximately 10″ from the floor. See figure 7-16 dimension “A.” Mark points where gauge contacts tires. NOTE: An accurate check also can be made by raising and rotating front wheels to scribe a fine line near the center of each tire, then, with tires on the floor and front spring trim height correct, measure between scribed lines with a suitable trammel.

- Roll the car forward until measuring points on tires are approximately 10″ from the floor at the rear, and measure the distance between points used in Step 3 above. The measurement at the front (dimension “A”) should be 1/16″ to 1/8″ less than the measurement at the rear (dimension “B”). See figure 7-16.

- If toe-in is not within specified limits, loosen clamp bolts and turn adjusting sleeves at tie rod ends as required. Decrease toe-in by turning left sleeve in same direction as wheel rotates moving forward and turn right sleeve in opposite direction. Increase toe-in by turning both sleeves in opposite direction.

CAUTION: Left and right adjusting sleeves must be turned exactly the same amount but in opposite directions when changing toe-in, in order to maintain front wheels in straight ahead position when steering wheel lower spoke is straight down.

- After correct toe-in is secured tighten clamp bolts securely.

Checking 1956 Buick Steering Geometry (Turning Angles)

CAUTION: Be sure that caster, camber, and toe-in have all been properly corrected before checking steering geometry. Steering geometry must be checked with the weight of the car on the wheels.

- With the front wheels resting on full floating turntables, turn wheels to the right until the outside (left) wheel is set at 20 degrees. The inside (right) wheel should then set at angle specified in figure 7-16.

- Repeat this test by turning front wheels to the left until the outside (right) wheel sets at 20 degrees; the inside (left) wheel should then set at angle specified in figure 7-16.

- Errors in steering geometry generally indicate bent steering arms, but may also be caused by other incorrect front end factors. If the error is caused by a bent steering arm it should be replaced. Replacement of such parts must be followed by a complete front end check as described above.

Leave A Comment

You must be logged in to post a comment.