SECTION 6-A 1955 BUICK REAR AXLE SPECIFICATIONS, DESCRIPTION TROUBLE DIAGNOSIS

6-1 1955 BUICK REAR AXLE SPECIFICATIONS

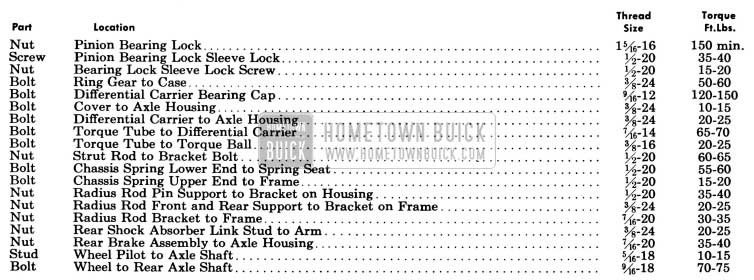

Tightening Specifications

Use a reliable torque wrench to tighten the parts listed, to insure proper tightness without straining or distorting parts. These 1955 Buick rear axle specifications are for clean and lightly lubricated threads only; dry or dirty threads produce increased friction which prevents accurate measurement of tightness.

1955 Buick Rear Axle Tightening Specifications

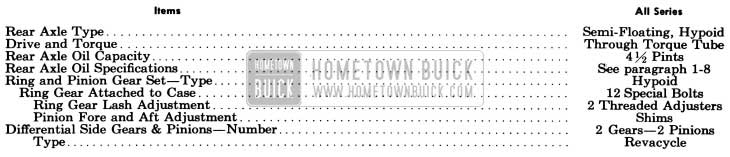

General Specifications

1955 Buick Rear Axle General Specifications

1955 Buick Rear Axle Gear Ratios

The following gear ratios are standard; optional gear ratios are not available. The 1955 Buick gear ratio is indicated by numbers stamped on bottom of axle housing.

1955 Buick Rear Axle Gear Ratios

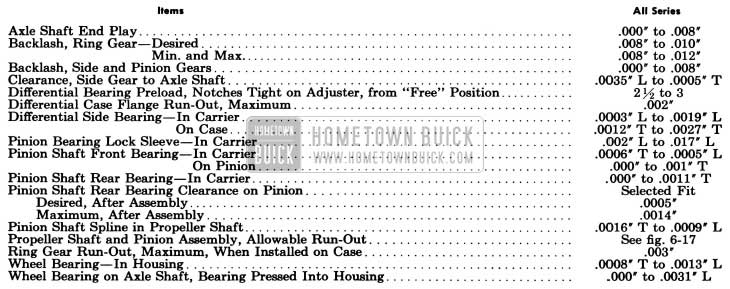

Limits for Fitting and Adjusting of Parts

NOTE: Limits on fit of parts are for new parts only. “T” means tight and “L” means loose.

1955 Buick Limits for Fitting and Adjusting of Rear Axle Parts

6-2 DESCRIPTION OF 1955 BUICK REAR AXLE

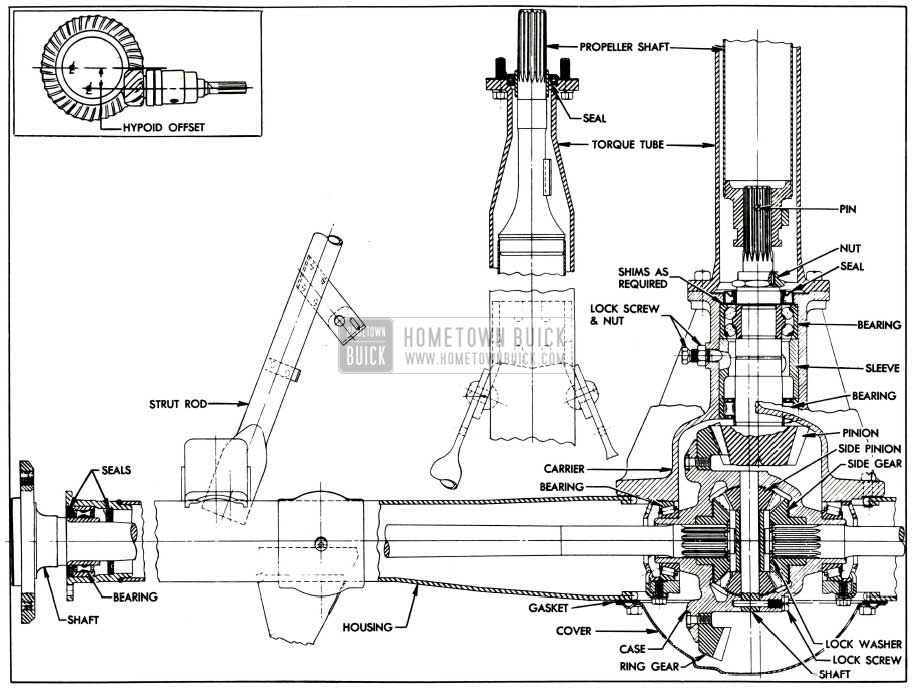

The 1955 Buick rear axle assembly is the semi-floating type in which the load is carried on the axle shafts through bearings enclosed in the axle housing. It has a torque tube drive and a Hypoid type spiral bevel ring gear and pinion set in which the centerline of the pinion is below the centerline of the ring gear. See figure 6-1.

1955 Buick Rear Axle Assembly

The torque tube is joined to the differential carrier to form a unit assembly called the third member housing; the torque tube and carrier are not serviced separately. The third member housing is bolted to the banjo type rear axle housing. Two rear axle strut rods form braces between the front end of the third member housing and the outer ends of the axle housing to hold third member square with axle housing.

The 1955 Buick torque tube encloses a tubular propeller shaft which is rigidly connected to the pinion through a splined joint and a pin. A seal mounted in the torque tube front flange bears against a sleeve pressed on the front end of propeller shaft to prevent passage of lubricant between the transmission and rear axle. See figure 6-1.

The pinion is supported in the differential carrier by one Hyatt roller bearing (rear) and a New Departure double-row radial-thrust ball bearing (front) which is secured to the shaft by a large lock nut staked in place. A spring loaded seal bears against the lock nut to prevent escape of oil from the rear axle housing into the torque tube.

The pinion and bearing assembly is held in position by a pinion bearing lock sleeve and three cone-pointed lock screws which clamp the double-row ball bearing against a shoulder in the carrier. Shims placed between the bearing and the shoulder provide correct relation of the pinion with ring gear. See figure 6-1.

The ring gear is bolted to the differential case which is supported in the differential carrier with two differential side bearings. Threaded adjusters bearing against the outer races of the side bearings provide means of adjusting ring gear lash. The differential case also houses two differential bevel side gears in mesh with two differential bevel side pinions mounted on a shaft which is anchored in the case by a lock screw. See figure 6-1.

The splined inner ends of the axle shafts are supported by the differential side gears. “Horseshoe” washers retain the axle shafts in the side gears; washers are held in recesses in side gears when differential pinion spacer is installed. The pinion spacer is located between the inner ends of the shafts and controls end play of axle shafts. The outer ends of the axle shafts are supported in the axle housing by Hyatt roller bearings. Seals are provided on both sides of each roller bearing to exclude dirt and to prevent leakage of oil upon the brakes.

6-3 1955 BUICK REAR AXLE TROUBLE DIAGNOSIS

Elimination of External Noises

When a 1955 Buick rear axle is suspected of being noisy it is advisable to make a thorough test to determine whether the noise originates in the tires, road surface, front wheel bearings, engine, transmission, or 1955 Buick rear axle assembly. Noise which originates in other places cannot be corrected by adjustment or replacement of parts in the 1955 Buick rear axle assembly.

- Road Noise. Some road surfaces, such as brick or rough surfaced concrete, cause noise which may be mistaken for tire or rear axle noise. Driving on a different type of road, such as smooth asphalt or dirt, will quickly show whether the road surface is the cause of noise. Road noise usually is the same on drive or coast.

- Tire Noise. Tire noise may easily be mistaken for rear axle noise even though the noisy tires may be located on the front wheels. Tires worn unevenly or which have the surfaces of the non-skid divisions worn in saw-tooth fashion are usually noisy, and may produce vibrations which seem to originate elsewhere in the vehicle. This is particularly true with low tire pressure. Some designs of non-skid treads may be more noisy than others, even when tires are new.

- Test for Tire Noise. Tire noise changes with different road surfaces but rear axle noise does not. Temporarily inflating all tires to approximately 40 pounds pressure, for test purposes only, will materially alter noise caused by tires, but will not affect noise caused by the 1955 Buick rear axle. Rear axle noise usually ceases when coasting at speeds under 30 miles per hour; however, tire noise continues but with lower tone as car speed is reduced. 1955 Buick rear axle noise usually changes when comparing “pull” and “coast,” but tire noise remains about the same.

- Front Wheel Bearing Noise. Loose or rough front wheel bearings will cause noise which may be confused with rear axle noise; however, front wheel bearing noise does not change when comparing “pull” and “coast.” Light application of brake while holding car speed steady will often cause wheel bearing noise to diminish as this takes some weight off the bearing. Front wheel bearings may be easily checked for noise by jacking up the wheels and spinning them, also by shaking wheels to determine if bearings are loose.

- Engine and Transmission Noises. Sometimes a noise which seems to originate in the rear axle is actually caused by the engine or transmission. To determine which unit is actually causing the noise, observe approximate car speeds and conditions under which the noise is most pronounced, then stop car in a quiet place to avoid interfering noises. With transmission in neutral, run engine slowly up and down through engine speeds corresponding to car speed at which the noise was most pronounced. If a similar noise is produced with car standing it is caused by the engine or transmission, and not the 1955 Buick rear axle.

1955 Buick Rear Axle Noises

If a careful test of the car shows that the noise is not caused by external items as described in subparagraph a, it is then reasonable to assume that the noise is caused by the 1955 Buick rear axle assembly. The 1955 Buick rear axle should be tested on a smooth level road to avoid road noise. It is not advisable to test rear axle for noise by running with rear wheels jacked up.

Noises in the 1955 Buick rear axle assembly may be caused by faulty rear wheel bearings, faulty differential or pinion shaft bearings, differential side gears and pinions worn, or by a mismatched, improperly adjusted or scored ring and pinion gear set.

- Rear Wheel Bearing Noise. A rough rear wheel bearing produces a vibration or growl which continues with car coasting with transmission in neutral. A brinnelled rear wheel bearing causes a knock or click approximately every two revolutions of rear wheel since the bearing rollers do not travel at the same speed as the rear axle and wheel. With rear wheels jacked up, spin rear wheels by hand while listening at hubs for evidence of rough or brinnelled wheel bearing.

- Differential Side Gear and Pinion Noise. Differential side gears and pinions seldom cause noise since their movement is relatively slight on straight ahead driving. Noise produced by these gears will be most pronounced on turns.

- Pinion Bearing Noise. Rough or brinnelled pinion bearings produce a continuous whine starting at relatively low Speed. The noise is most pronounced on light load drive between 20 and 35 miles per hour.

- Ring and Pinion Gear Noise. Noise produced by the ring and pinion gear set generally shows up as drive noise, coast noise, or float noise.

- Drive noise is most evident on constant acceleration through the speed range.

- Coast noise is most evident when car is allowed to coast through the speed range with throttle closed.

- Float noise is most evident while just barely holding the car speed constant on a level road at any speed.

- Drive, coast, and float noises will be very rough and irregular if the differential or pinion shaft bearings are rough, worn, or loose, and will vary in tone with speed.

Check for 1955 Buick Propeller Shaft Vibration

Objectionable vibrations at high speed (65 m.p.h. or higher) may be caused by a propeller shaft that is out of balance. Out of balance may be due to a bent shaft or presence of oil in the shaft.

To determine whether the propeller shaft is causing vibration, drive car through the speed range and note car speed at which vibration is most pronounced. Shift transmission into second gear (synchromesh) or low range (Dynaflow) and drive car at same engine speed as when vibration was most pronounced in direct drive, and note the effect on vibration.

To determine the required engine speed, divide car speed by the transmission gear ratio, using 1.6 for synchromesh or 1.8 for Dynaflow Example: If vibration is most pronounced at 65 m.p.h. in direct drive, the same engine speed would be produced in

second gear (synchromesh) at 65/1.6 = 40 m.p.h.,

or in low range (Dynaflow) at 65/1.8 = 36 m.p.h.

If the vibration is still present at the same engine speed whether in direct drive or in the lower gear then the propeller shaft is not out of balance. If the vibration decreases or is eliminated in the lower gear then the propeller shaft is out of balance and should be removed for correction.

What is a complete Buick axel in working order worth, currently on a trailer, about 1935