SECTION 1-A 1955 BUICK LUBRICARE INSTRUCTIONS CONTENTS OF SECTION 1-A

1-1 EVERY 1000 MILES- 1955 BUICK LUBRICARE

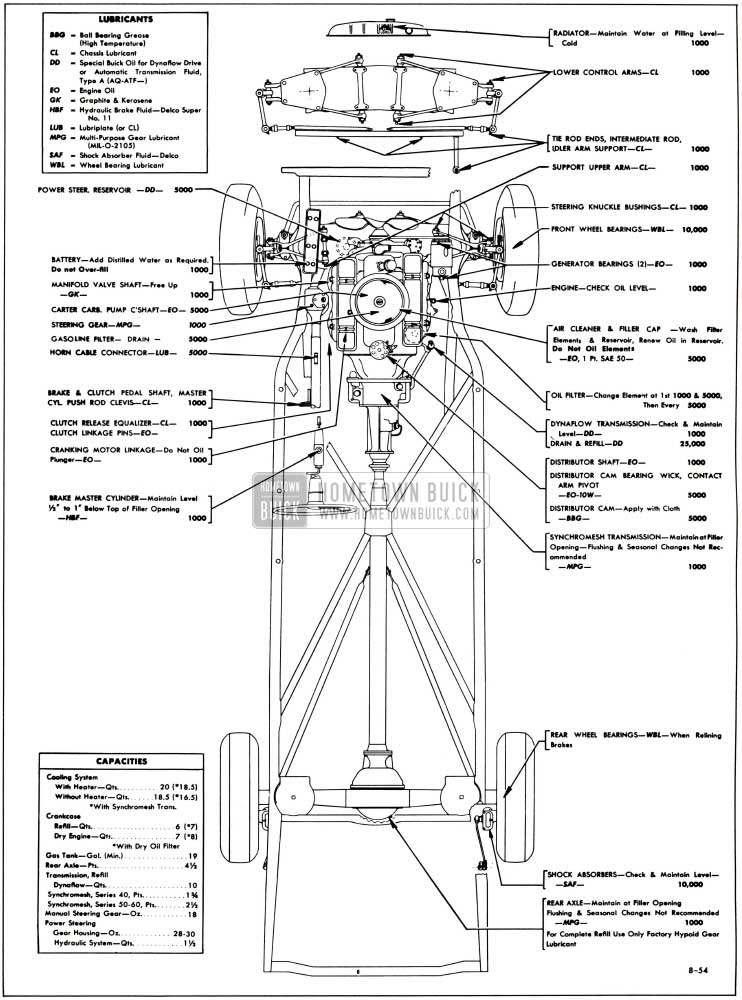

Chassis Lubricare

- Check engine oil level only after engine has been stopped for at least three to five minutes to allow oil to drain down.

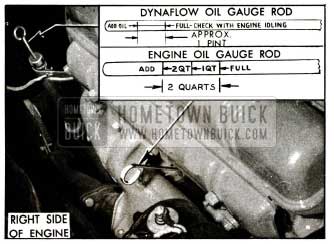

The oil level should be maintained between the “FULL” and “ADD” marks on gauge rod; the space between marks represents 2 quarts. It is best to maintain the oil level within one quart of the “FULL” mark. Do not fill above the “FULL” mark. See figure 1-3.

1955 Buick Engine and Dynaflow Oil Gauge Rods

See paragraph 1-7 for engine oil recommendations and when to change oil.

- Front suspension, Brake, Clutch and Transmission Controls. Wipe dirt from lubrication fittings, then apply a good grade of water resistant chassis lubricant, under pressure, at the following points (fig. 1-1):

1955 Buick Chassis Lubricare Chart

- Lower Control Arms, inner and outer ends

- Support Upper Pivot Pins

- Steering Knuckle Bushings

- Tie Rod Ends, Intermediate Rod, and Idler

- Arm Support Bushing.

- Clutch Release Equalizer

- Brake Pedal, lower end at push rod clevis. Brake and Clutch Pedal Shaft

- Clutch Pedal Linkage Pins, lubricate with engine oil.

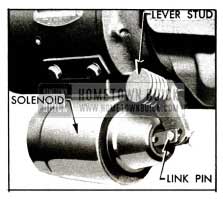

- Cranking Motor (Starter). Apply a few drops of engine oil to the solenoid link pin and to the bearing between shift lever and stud. See figure 1-2. Do not oil Solenoid plunger.

1955 Buick Cranking Motor Shift Linkage

If oil level is more than one inch below the “FULL” mark on gauge rod, add oil specified in paragraph 1-4 but do not fill above the “FULL” mark. Distance between the “FULL” and “ADD OIL” mark is one inch and represents approximately one pint.

- Fill oil cup with SAE 10W engine oil.

- Air Cleaner. Normally serviced every 5000 miles. If car is operating in dusty territory, however, check condition of air cleaner and clean it if dirty. See instructions in paragraph 1-2.

- Generator; Fan Belt. Add 8 to 10 drops of low engine oil to oiler at drive (pulley) end of generator and fill rear oiler to the cap. Wipe off excess or spilled oil. Never lubricate the commutator and do not lubricate generator while it is operating.

If oil reserve in commutator end bearing is exhausted due to failure to lubricate at proper intervals, the rear oil cup should be filled 3 times, allowing time for each filling to soak down.

Inspect fan belt for cracks and for proper tension. See figure 2-37.

- Check coolant level when engine is cold and add water to line marked “Filling Level-Cold” stamped on rear side of head tank. See figure 1-4.

1955 Buick Radiator Filling Level-Cold

CAUTION: Radiator cap should not be removed when engine is hot because relieving the pressure may cause the cooling system to boil, with resultant loss of water or anti-freeze solution. Filling radiator when hot, or filling above level line may result in loss of water or anti-freeze solution through overflow pipe.

1955 Buick Battery Filler Well

WARNING: Do not overfill. Clean top of battery; if wet with acid, neutralize with soda and wash clean.

1955 Buick Manifold Valve

Thoroughly clean filler cap nut before removal to avoid getting dirt into reservoir. Add fluid as required to bring level to %” to 1″ below top of filler opening. Use G.M. or Delco Super No. 11 Hydraulic Brake Fluid. Never use reclaimed fluid or any mineral oil.

- Inflate all tires according to tire temperatures, as follows:

24 lbs. Starting Pressure-after car has been standing for 3 hours or driven less than one mile.

26 lbs. City Pressure-after car has been driven 3 miles or more BELOW 40 MPH.

28 lbs. Highway Pressure-after car has been driven 3 miles ABOVE 40 MPH.

WARNING: It is impossible to inflate tires correctly when HOT. Pressure normally increase s as tires heat up when driving. Do not deflate tires to offset this increase in pressure.

1955 Buick Body Lubricare

- Hood Latch and Hinges. Lightly coat hood latch, lever, and dovetail bolt with Lubriplate. Apply engine oil to hood hinge pins.

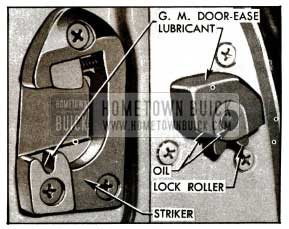

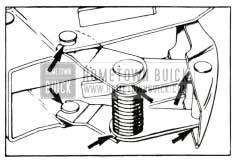

- Door Locks and Strikers-Series 40-60. Remove dirt and old lubricant from door locks and strikers. Apply one or two drops of SAE 10 engine oil to lock roller pins, and apply a light coat of G.M. Door-Ease Lubricant to top surface of lock roller housings and to teeth in strikers. Wipe off excessive lubricant. See figure 1-7.

1955 Buick Door Lock and Striker-Series 40-60

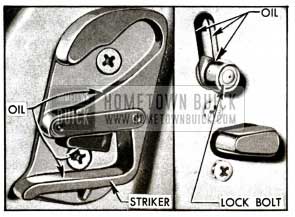

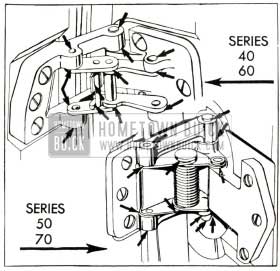

Door Locks and Strikers-Series 50-70. Remove dirt and old lubricant from lock bolts and strikers. Apply light film of SAE 10 engine oil at rollers and bolts, edges of bolt slots, guide channels in strikers, surface of bumpers; wipe off surplus oil. See figure 1-8. Do not use heavy bodied lubricants, as these tend to gum up and hinder free movement of lift type lock bolts.

1955 Buick Door Lock and Striker-Series 50-70

1-2 EVERY 5000 MILES – 1955 BUICK LUBRICARE

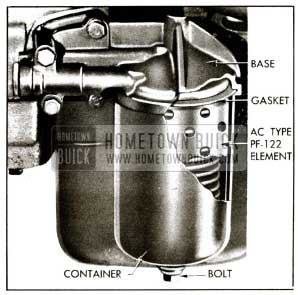

- Oil Filter. Change original filter at first 1000 miles, the second element at first 5000 miles, then change element at each 5000 mile interval thereafter.

Loosen the container bolt and allow oil to drain out. Remove container, element, old gasket. See figure 1-9.

1955 Buick Oil Filter

Wash and dry container and make sure that gasket surfaces are clean. Install new type G-270 gasket in undercut in filter base; then install new AC Type PF-122 element and old container, tightening bolt securely. Check for oil leaks after engine has run for 5 minutes.

- Apply a few drops of 10W engine oil to felt wick in top of cam under the rotor. Put one drop of 10W oil on breaker arm pivot. Work a small amount of M-1172 ball bearing grease (available through U.M.S.) into a clean cloth, then hold cloth against distributor cam while it is rotating. CAUTION: Excessive grease may throw off into contact points when hot. Petroleum jelly is not suitable for temperature reached by distributor cam.

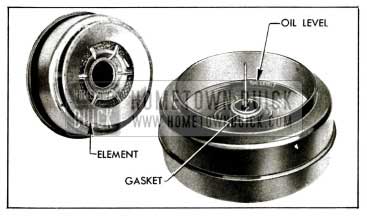

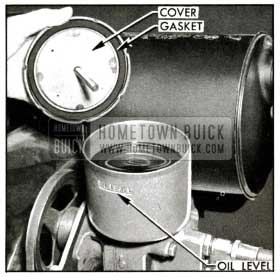

- Air Cleaner and Oil Filler Cap. Every 5000 miles (more often under dusty operating conditions) remove the air cleaner element and the oil filler cap and wash the filtering elements in a non-inflammable solvent. DO NOT USE KEROSENE. Allow elements to drain until dry. Do not use air blast on filtering element.

Wash and dry the air cleaner reservoir then fill to point marked “OIL LEVEL,” using one pint of SAE 50 engine oil. See figure 1-10. Do not oil the cleaner element because oil will drain down into reservoir and over-fill it.

1955 Buick Air Cleaner Element and Reservoir-Series 40

Make sure that gasket at center of cleaner element is in good condition before parts are installed. Wipe all oil from outer surface of air cleaner and filler cap.

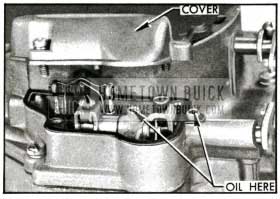

- Pump Operating Countershaft – Carter Carburetor Only. On the 2-barrel carburetor, remove dust cover screws, apply several drops of engine oil in screw holes and install screws. On the 4-barrel carburetor, remove dust cover and apply oil in two oil holes above countershaft. See figure 1-11.

1955 Buick Counterhaft Lubrication-Carter 4-Barrel

1955 Buick Oil Pump Reservoir

1955 Buick Door Check and Hold-Open Link

Apply lubriplate solution (*) to rear door lower hinges at pivot points indicated by arrows in figure 1-14.

1955 Buick Rear Door Lower Hinge

*Prepare Lubriplate solution by dissolving 1/4 pound of No. 630 AA Lubriplate in one pint of mineral spirits.

1-3 EVERY 10,000 MILES – 1955 BUICK LUBRICARE

- Front Wheel Bearings. Inspect, repack, and adjust front wheel bearings as described in paragraph 6-14.

Inspect Brake Linings and Drums while front wheels are off. If linings are thin or drums are beginning to score, the car owner should be notified.

- Shock Absorbers-Rear. Check fluid level as specified in paragraph 7-15.

1-4 EVERY 25,000 MILES – DYNAFLOW TRANSMISSION

At 25,000 mile intervals the transmission should be completely drained, the oil pan and screen should be removed and cleaned, and the transmission should be refilled with fresh oil. Transmission MUST NOT BE FLUSHED when oil is changed.

Approved Oils for Dynaflow Transmission

The following oils are approved for Dynaflow Drive and no other fluid should be used.

- Special Buick Oil for Dynaflow Drive, available through Buick Parts Warehouses under Group 4.101.

- Automatic Transmission Fluid, Type A, available through petroleum suppliers. This fluid must have an AQ-ATF number embossed in lid of the can for identification.

Draining and Refilling Dynaflow Transmission

- Warm up transmission, then remove bell housing cover.

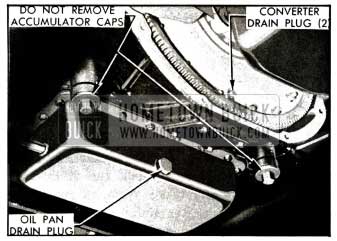

- Loosen one converter drain plug, through opening in flywheel, then turn flywheel until opposite drain plug is straight down and remove this plug to allow converter to drain completely. See figure 1-15.

1955 Buick Dynaflow Transmission Drain Plugs

A transmission refill requires approximately 10 quarts total. A completely dry transmission requires an additional 1 3/4 pints.

1-5 1955 BUICK LUBRICARE – AS REQUIRED

1955 Buick Clutch Internal Lubricare

Lubrication of internal working parts of the clutch is usually required only at time clutch is assembled and installed; however, if lubrication becomes necessary to eliminate squeaks or correct excessive pedal pressure, follow instructions given in paragraph 4-4.

1955 Buick Brake Lubricare

Lubrication of all metal contact points at wheel brake assemblies is normally performed during the major brake adjustment or may be performed whenever a brake drum is removed.

Lubrication of parking brake cables is also performed during the major brake adjustment; however, operation under conditions where mud and water are frequently encountered may require more frequent lubrication. See paragraph 9-9.

1955 Buick Rear Wheel Bearing Lubricare

Rear wheel bearings need not be lubricated more often than 20,000 miles. Whenever rear brakes are relined, or axle shafts are removed for other work, it is advisable to inspect rear wheel bearings and oil seals. Replace seals if leaking or worn. Fill rear wheel bearings and space between oil seals with wheel bearing lubricant, allowing some expansion space-do not pack full. Coat leather edges of seals with lubricant before installation of axle shaft.

1955 Buick Speedometer Cable Lubricare

The speedometer cable is factory lubricated with special all-season grease and normally requires no further service unless it becomes noisy. In extremely hot climates or where considerable dirt and water are encountered, however, it may be necessary to lubricate the cable at intervals of approximately 20,000 miles or every two years. See paragraph 10-58.

1955 Buick Sunshade Lubricare

If the sunshade rod turns hard in the support as sunshade is moved up and down, remove retainer screw, pull rod from support and apply G. M. Door-Ease Lubricant. Do not use oil, which may soil body trim. Install rod in support and adjust retainer screw to proper tension.

1955 Buick Roof Side Rail Sealing Strip

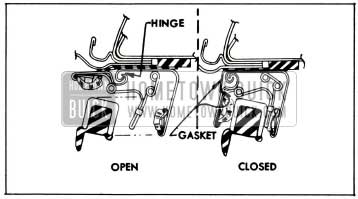

The mechanical (“flipper”) type sealing strips mounted on the roof side rails above the doors on some models should be lubricated occasionally to insure proper operation and minimum wear.

- Open the door and apply a coat of Lubriplate No. 107 or No. 110 to entire length of hinge indicated in figure 1-16. Wipe off any excess. Do not apply this lubricant to the awning gasket.

1955 Buick Sealing Strip Lubricare

1-6 1955 BUICK ENGINE OIL RECOMMENDATIONS

Choice of 1955 Buick Engine Oil

- Brand of Oil. In the selection of the proper brand of oil it is essential to consider the reputation of the refiner or marketer. It is imperative that the same brand of oil be used at all times.

- Type of Oil. There are several types of oil manufactured for use in internal combustion engines. For use in the Buick engine we recommend that a heavy duty type oil marked “For Service MS” or “For Service DG” be used for maximum protection under all driving conditions. Oils marked “For Service MM” or “For Service ML” are not recommended for any Buick engine.

- Grade or Viscosity. The grade or viscosity (SAE number) of engine oil should be selected for the lowest anticipated temperature at which cold engine starting will be required as follows:

- Temperature – SAE Grade

Not lower than 32° F. – 20-W

Not lower than minus 10° F. – 10-W

Below minus 10° F. – *5-W - Break-in Oils. Break-in oils or compounds are not necessary in Buick engines and their use is not recommended. Some of these break-in oils contain certain materials which may be harmful. Buick HD Concentrate (subpar. d) is not a break-in oil.

When to Change 1955 Buick Engine Oil

The crankcase should be completely drained and refilled with new oil of proper viscosity at the end of the first 1,000 miles and every 2,000 to 3,000 miles thereafter. Adverse driving conditions may require more frequent draining and refilling. Adverse driving conditions are those which may cause early contamination of engine oil, such as operation under unusual dust conditions or short runs with a cold engine in very cold weather.

The color of “Service MS” type oil does not indicate its condition since it normally becomes dark (black or gray) after only a few hundred miles of driving. This is because the detergent content envelopes and holds in suspension extremely fine but harmless soot (soft carbon) and lead particles. The oil filter element does not remove this harmless material but it does remove all harmful particles such as road dust, metal chips and hard carbon.

1955 Buick Crankcase Flushing

Flushing the crankcase with oils or solutions other than a good grade of 10-W engine oil is not recommended. When flushing to remove contamination appears advisable, use 3 quarts 10-W oil (4 quarts if filter is drained) and idle the engine at 1000 RPM (equivalent to 20 MPH) until the oil is hot, then drain crankcase and oil filter immediately after stopping engine. Fill crankcase with correct quantity and seasonal grade of oil.

Use of Buick HD Concentrate

Buick HD Concentrate, available through Buick Parts Department under Group 1.850 is a compound of the materials used by oil refiners to manufacture high detergency motor oils. It is intended for use in engines operating under aggravated conditions where engine deposits, rust and corrosion cannot be adequately retarded by motor oils readily available to the average motorist. It is especially recommended for engines operated under restricted conditions such as frequent stops, short trips and slow Speeds where such symptoms as sticking valves, valve lifters and rings are noticed.

Although HD Concentrate may be used continually it is normally unnecessary to use it with every crankcase refill. When used, the instructions on the container should be carefully observed.

1-7 1955 BUICK REAR AXLE LUBRICANT RECOMMENDATIONS

1955 Buick Lubricant Recommendations

Buick rear axles are filled at the factory with a special hypoid gear lubricant. It is not necessary to drain the original lubricant at any time except when it has become contaminated, or when draining is required for inspection of parts or for repairs.

Under no circumstances should the factory lubricant be drained from the rear axle to be replaced with any other type of lubricant.

In all cases of complete refilling of rear axle only Factory Hypoid Gear Lubricant is recommended. This is the same lubricant (lead soapactive sulphur type) as furnished with Buick replacement ring and pinion gear sets, and it may be obtained from any Buick Parts Warehouse under Group 5.535.

When adding lubricant to bring it to proper level Factory Hypoid Gear Lubricant is preferred; however, SAE 90 Multi-Purpose Gear Lubricant (MIL-0-2105) may be used.

Draining, Flushing and Refilling 1955 Buick Rear Axle

If rear axle lubricant has become contaminated, the rear axle should be drained, flushed, and refilled with new lubricant as follows:

- With rear axle jacked up so that wheels are clear of the floor, clean bottom of body, rear end of chassis and the rear axle housing to remove loose dirt which might get into rear axle when housing cover is removed. DO NOT TAKE CHANCES ON GETTING ABRASIVE SUBSTANCES INTO AXLE HOUSING OR BEARINGS.

- Drain rear axle housing by removing lower cover bolts, then remove cover.

- Thoroughly flush rear axle housing with SAE-10-W engine oil or flushing oil. Do not use water, steam, gasoline, kerosene, alcohol or other cleaning fluids for flushing.

Use a clean suction gun to flush all parts with clean oil, working a flow of oil through all bearings and working parts. Do not recirculate oil, but allow it to drain out as used.

- Wipe out axle housing with clean, lint free cloths. Install cover using a new gasket and coating threads of bolts with Permatex or thread sealer to avoid oil leaks. Install a new gasket on filler plug and tighten plug firmly.

- Refill rear axle housing to filler plug opening with Factory Hypoid Gear Lubricant (Group 5.535).

Leave A Comment

You must be logged in to post a comment.