SECTION 9-D 1955 BUICK POWER BRAKES

9-15 DESCRIPTION OF 1955 BUICK POWER BRAKE MECHANISM

General Description

Wheel brake assemblies used with 1955 Buick power brake mechanism are identical with the regular (foot powered) brake equipment, except that a high pressure type of brake shoe lining is used on the front secondary shoes. This lining is identified by its black colored edge.

The 1955 Buick power brake installation has a vacuum actuated power brake cylinder in place of the master cylinder used in the regular hydraulic brake system. The brake cylinder is mounted on the car frame under the body and is connected to the brake pedal by an extended push rod. Reserve fluid is carried in a separate reservoir located under the hood, on the left side, and connected to the hydraulic section of the brake cylinder by a short pipe.

The 1955 Buick power brake cylinder utilizes engine manifold vacuum in its operation, as described later, therefore it is connected to the intake manifold through pipes and flexible connections. A vacuum reserve tank of approximately 180 cubic inches capacity is connected into the vacuum line near the power brake cylinder to insure quick and smooth response of the brake cylinder on all power brake applications. A check valve installed in the vacuum line closes to maintain existing vacuum at the 1955 Buick power cylinder and in the reserve tank whenever manifold vacuum falls below that in the brake system.

When the engine is stopped and check valve is closed, the tank provides sufficient reserve vacuum for two or three normal power brake applications. When reserve vacuum does not exist, the brakes cable applied manually in the same manner as the regular (foot powered) brakes, except that somewhat more effort is required because of the reduced leverage of the 1955 Buick power brake pedal. Since brake application is normally assisted by vacuum, low pedal leverage is used to reduce the total pedal travel.

Construction of 1955 Buick Power Brake Cylinder

The 1955 Buick power brake cylinder is the “air suspended” type, meaning that atmospheric pressure is present on both sides of the power piston in the unapplied stage. In the “vacuum suspended” type used in 1953-54 models, vacuum exists on both sides of power piston in the unapplied stage, when engine or vacuum pump is running.

1955 Buick Unapplied Stage

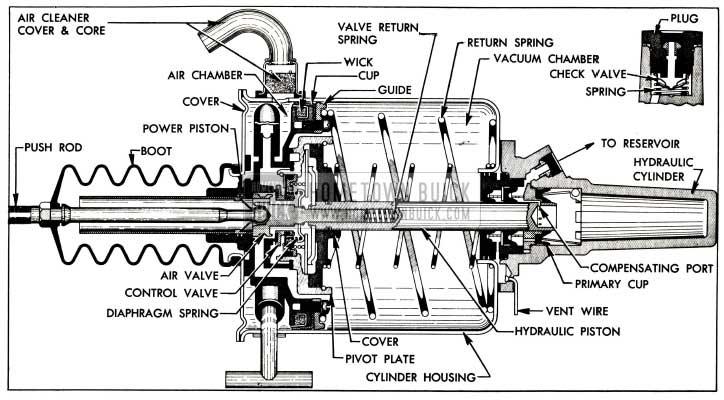

As shown in figure 9-13, a cover closes the forward end of the cylinder housing to form a large chamber in which the power piston and related parts operate. The section on the cover side of the piston will be called the air chamber since it is open to atmospheric pressure at all times. The section on the opposite side of the piston will be called the vacuum chamber since it is subjected to manifold vacuum during power application of brakes. All air entering the cylinder housing passes through an air cleaner core.

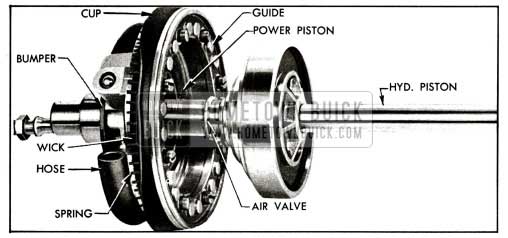

The rim of power piston carries a spring expanded leather cup and a felt lubricating wick to seal against passage of air, and an attached guide provides a bearing in the cylinder housing. A flexible rubber hose connecting the piston with a vacuum tee on the side of cylinder housing permits the piston to move back and forth while connected to manifold vacuum. Air is exhausted out of the vacuum chamber through passages in the piston and the vacuum hose when the control valve is set for power application.

The related parts which operate in the cylinder housing with the power piston form a separate assembly composed of: the air valve, floating control valve, hydraulic piston, and the reaction mechanism housed in a pivot plate and cover. This valve and hydraulic piston assembly moves with the power piston as one unit during power application of brakes, but moves alone during manual application, as explained later. A relatively heavy coil return spring is used for the power piston and a smaller and lighter return spring is used for the valve and hydraulic piston assembly.

The hydraulic piston is a solid steel plunger which extends into the hydraulic cylinder through a rubber vacuum cup seal and rubber secondary and primary cups. To prevent vacuum from drawing brake fluid out of hydraulic cylinder in case of seal leakage, the space between the vacuum cup seal and the secondary cup is vented to atmosphere through a hole which is kept open by a loose wire.

Movement of the piston into the fluid filled cylinder displaces a corresponding volume of the fluid, which is forced out into the brake pipes and wheel cylinders. Compensating ports in the counterbored end of the piston permit return of surplus fluid to reservoir when brakes are released. The check valve and spring in the hydraulic cylinder maintains static pressure in brake pipes and wheel cylinders.

Operation of 1955 Buick Power Brake Cylinder

Description of 1955 Buick power brake cylinder operation will cover (1) Unapplied Stage (2) Applied Stage (3) Reaction Pressure (4) Poised Stage (5) Releasing Stage (6) Manual Application.

(1) Unapplied Stage. See figure 9-13. The pedal return spring holds the push rod and attached air valve forward so that the air valve is held clear of the floating control valve. At the same time, the valve diaphragm spring holds the floating control valve against its seat on the power piston, thereby closing the passage connected to manifold vacuum.

Atmospheric pressure enters through the air cleaner into the air chamber, flows through the boot and air valve into the space between the air valve and the floating control valve, then flows through passages in power piston and out between piston and pivot plate into the vacuum chamber. With the vacuum passage closed and the vacuum chamber open to outside air, the power piston is balanced by atmospheric pressure on both sides and is held against the housing cover by the return springs.

The compensating ports in counterbored end of hydraulic piston are forward of the primary cup, permitting flow of brake fluid between the reservoir and hydraulic cylinder as required. The check valve is seated to maintain static pressure in the brake pipes and wheel cylinders.

(2) Applied Stage. See figure 9-14.

1955 Buick Applied Stage, With Reaction Pressure

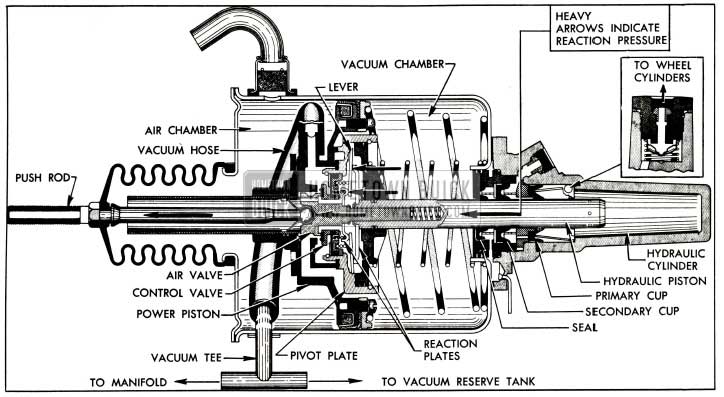

As the brake pedal is depressed the push rod moves the air valve rearward until its annular seat contacts the floating control valve, at which point atmospheric pressure is sealed off from the vacuum chamber. Further movement of the air valve pushes the floating control valve away from its seat on the 1955 Buick power piston, thus connecting the vacuum chamber to manifold vacuum through passages in power piston and the attached vacuum hose. As air is exhausted out of the vacuum chamber, atmospheric pressure in the air chamber moves the power piston rearward toward the hydraulic cylinder. The pivot plate is sealed to the power piston and the valve and hydraulic piston assembly moves rearward as a unit with the power piston.

As the hydraulic piston is forced into the hydraulic cylinder, escape of fluid into the reservoir is cut off when the piston compensating ports pass through the primary cup, and the fluid displaced by the piston is then forced out into the brake pipes and wheel cylinders to apply the brake shoes. At the same time, a reaction pressure is transmitted back to the brake pedal to give the driver an indication or “feel” of the pressure being applied to the brake shoes.

(3) Reaction Pressure. As pressure is built up in the brake pipes and wheel cylinders during brake application, the hydraulic piston is subjected to the same pressure. Since the piston is free to move forward in the pivot plate cover, the pressure on the piston is transmitted through the attached reaction plate to the six reaction levers. The outer ends of the levers press against pivot points in the pivot plate and the inner ends press against the valve reaction plate which now bears against a shoulder of the air valve. See figure 9-14.

In this manner approximately 40% of the load on the hydraulic piston is transferred through the air valve and push rod to the brake pedal to oppose the foot pressure applied by the driver. This reaction pressure gives the driver a definite indication or “feel” of the pressure being applied to the brake shoes so that he has positive control over the braking operation at all stages.

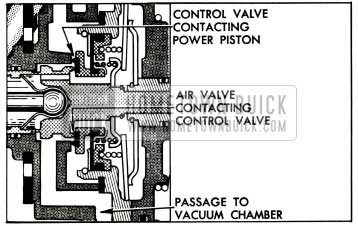

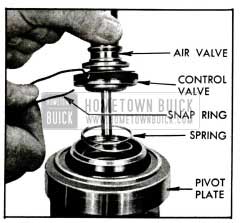

(4) Poised Stage. When the desired brake apply pressure is reached and brake pedal is held poised, the 1955 Buick power piston continues rearward momentarily until it contacts the floating control valve. See figure 9-15.

1955 Buick Valves at Poised Stage

At this point, the air valve is also in contact with the control valve so that the passages to the vacuum chamber are sealed off from atmospheric pressure as well as vacuum; therefore the power piston remains stationary or poised, ready to move in either direction as dictated by brake pedal movement.

(5) Releasing Stage. When foot pressure on brake pedal is released, the pedal return spring pulls the push rod forward to relieve pressure on the air valve. The valve return spring forces the air valve away from the floating control valve, which is seated against the power piston to close the vacuum passage. Since both sides of the power piston are now open to atmospheric pressure, the piston return springs force the power piston and related parts forward to the unapplied position (fig. 9-13).

As the hydraulic piston moves out of the hydraulic cylinder the fluid from the wheel cylinders flows back into the hydraulic cylinder through the check valve. When the compensating ports in the piston pass forward through the primary cup, any surplus fluid in the hydraulic system can return to the reservoir. The check valve spring presses the check valve against its seat with sufficient pressure to maintain some static pressure in the brake pipes and wheel cylinders.

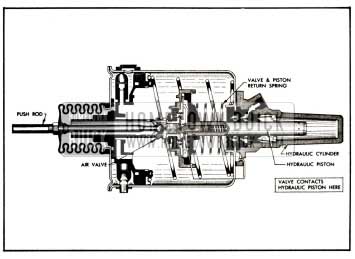

(6) Manual Application. When the engine is not running and reserve vacuum is exhausted, the brakes are applied entirely by foot pressure on the brake pedal. As the pedal is depressed, a shoulder on the air valve pushes against the end of the hydraulic piston so that pedal pressure is applied directly to the piston to force it into the hydraulic cylinder. As the valve and hydraulic piston assembly moves rearward, the power piston remains in the unapplied position, where it is held against its stop by its return spring. See figure 9-16.

1955 Buick Manual Application

This separation of the power piston from its related parts eliminates compression of the heavy return spring, friction of the leather piston cup against the cylinder housing, and movement of air out of the vacuum chamber; consequently the pedal pressure required for manual application is much lighter than if the power piston had to be moved. The only resistance offered in the cylinder housing is the relatively light spring used to return the valve and hydraulic piston assembly to the unapplied position on release of brake pedal.

If the engine should start running while brakes are being manually applied, manifold vacuum would exhaust air from the vacuum chamber through the wide open passages in the power piston, and the power piston would move rearward and seal to the pivot plate as shown in figure 9-14.

9-16 REMOVAL, INSTALLATION, ADJUSTMENT OF 1955 BUICK POWER BRAKE CYLINDER

Removal, Installation of 1955 Buick Power Brake Cylinder

- Remove cranking motor splash pan.

- Disconnect return spring, loosen lock nut on cylinder push rod, remove clevis pin at brake pedal, then unscrew pedal push rod from cylinder push rod.

- Disconnect air inlet hose at air filter on brake cylinder, and disconnect hoses from vacuum tee on opposite side of cylinder.

- Disconnect the reservoir to hydraulic cylinder pipe, allow reservoir and pipe to drain. Disconnect distributor to cylinder pipe and allow to drain. Discard old fluid and cover pipe ends with tape to exclude dirt.

- Remove nuts and lockwashers attaching 1955 Buick power brake cylinder to its support and remove cylinder from car.

- Install 1955 Buick power brake cylinder by reversing the procedure for removal. Adjust push rod as described below (subpar. b) before installing splash pan.

- After installation is completed, bleed the hydraulic system (par. 9-7) and then make sure that reservoir is filled to proper level.

- Check brake system for fluid leaks while applying heavy pressure on brake pedal, with engine running.

Adjustment of 1955 Buick Brake Pedal and Push Rod

- Make certain that brake pedal is properly lubricated and moves freely on its shaft, also that it does not bind on floor mat.

- Make certain that push rod is securely locked in air valve of 1955 Buick power brake cylinder and that boot is properly seated on push rod and flange of housing cover.

- Connect pedal push rod to brake pedal with clevis pin and cotter pin, then check for free movement of pedal and push rod. If a bind exists, loosen pedal shaft bracket bolts to permit bracket to shift to a free position and tighten bolts securely.

- Connect the pedal return spring, then screw the cylinder push rod in or out of pedal push rod until pedal grommet is compressed to approximately %” after it contacts toeboard with pedal in released position.

- Start engine and apply brakes several times, then check for full release of brakes at each wheel. If brakes drag, readjust push rod. If push rod is too long, compression of the pedal grommet may prevent proper opening of cylinder air valve in brake released position.

9-17 DISASSEMBLY, INSPECTION, ASSEMBLY OF 1955 BUICK POWER BRAKE CYLINDER

Disassembly of 1955 Buick Power Brake Cylinder

NOTE: Refer to figures 9-13 and 9-11, for identification of parts not otherwise illustrated.

- Mount 1955 Buick power brake cylinder in vise with hydraulic cylinder down, being careful not to damage the loose vent pin in flange of cylinder. Tighten vise only enough to hold cylinder firmly; excessive tightening will distort or crack cylinder.

- Remove push rod boot and retainer from housing cover. Do not attempt to remove push rod which is anchored in air valve by a spring type lock.

- Remove air cleaner assembly and disassemble it by removing the screw, gasket, filter core, and spring from the cover.

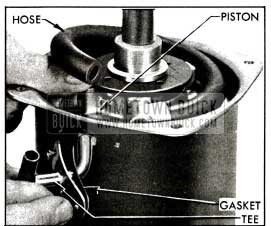

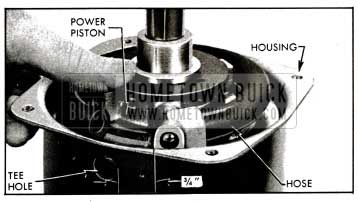

- Remove housing cover bolts, cover, and gasket. While holding power piston down, disconnect vacuum hose from vacuum tee and remove tee and gasket from housing. See figure 9-17.

1955 Buick Removing Vacuum Tee

Slowly release power piston to control the pressure of piston return springs as piston and attached parts emerge from housing. Make sure that lip of leather piston cup does not catch in holes in housing.

1955 Buick Power Piston With Air Valve and Hydraulic Piston Assembly

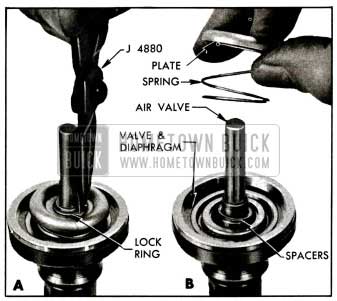

1955 Buick Removing Control Valve from Air Valve

1955 Buick Removing Air Valve with Control Valve

1955 Buick Hydraulic Piston and ttached Parts

1955 Buick Removing Cylinder Plug

Cleaning, Inspection, Replacement of 1955 Buick Power Brakes Parts

As an aid in determining the cause of improper 1955 Buick power brake operation, wipe fluid from all rubber parts, then carefully examine these parts for nicks, cuts or other damage. After examination discard all these parts.

Thoroughly clean the remaining parts in diacetone alcohol or clean brake fluid.

CAUTION: Do not use anti-freeze alcohol, gasoline, kerosene, or any other cleaning fluid that might contain even a trace of mineral oil, as this could cause serious damage to all rubber parts in the brake system.

Carefully examine the cleaned parts for nicks, burrs, stripped threads, or other damage. Make certain that the small compensating ports in end of hydraulic piston are clear. If these ports are plugged, clean them thoroughly and flush the hydraulic system to remove all dirt.

If the outer surface of the air valve or the hydraulic piston show evidence of abrasion, polish out light scores with crocus cloth or very fine polishing paper, then wash and dry thoroughly.

If any parts indicate that heavy abrasive action has resulted from severe contamination of the brake fluid, replace damaged parts and be sure to thoroughly flush the reservoir and wheel cylinder lines.

Make sure that the loose pin is properly retained in vent hole in flange of hydraulic cylinder body, and that vent hole is clear.

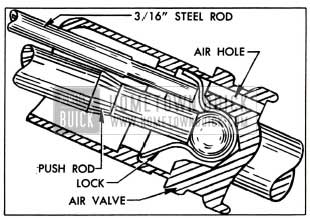

Do not remove push rod from air valve unless one part is damaged so that replacement is required. To unlock the push rod, prepare a piece of 3/16″ steel rod about 7″ long by filing fiats on one end to reduce size to 5/32″, then use as a punch to bend both arms of push rod lock as shown in figure 9-23.

1955 Buick Bending Push Rod Lock

Grip hex of push rod in vise and pull on air valve to separate these parts, then insert thin metal strips through air holes in valve to remove the lock. Use care to avoid damaging the annular seat on air valve.

The 1955 Buick Power Brake Cylinder Overhaul Kit (Group 4.898) contains all necessary replacement parts for the power brake cylinder. When reassembling the brake cylinder use all the new parts in the kit regardless of whether the old parts appear fit for use. In addition, replace any other parts which inspection indicates to be unfit for use.

Assembly of 1955 Buick Power Brakes Cylinder

NOTE: Refer to figures 9-13 and 9-14 for identification and location of parts not otherwise illustrated.

- Mount hydraulic cylinder body in vise with flanged end up.

CAUTION: During assembly make certain that no grease or mineral oil comes in contact with internal parts of hydraulic cylinder.

- Install new valve seat washer and new gasket on head nut. Place spring and new check valve (concave side outward) in cylinder body then install head nut and tighten securely.

- Place primary cup retainer in cylinder body with notched end inward. Dip new primary cup in clean brake fluid and install with flat side outward, using care that cup lip is not turned back at any point. Center the primary cup ring on cup and install piston bearing with notched face outward, pressing bearing down against shoulder in body.

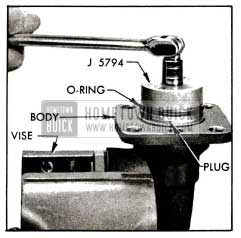

- Dip new vacuum seal and secondary cup in clean brake fluid. Install seal in cylinder plug with flat side inward, center the seal retainer in seal, then install cup support against shoulder in plug. Install secondary cup with flat side inward against the support. Place new O-ring in the two outer grooves of plug and lightly coat them with silicone grease.

- Center the secondary cup retainer on piston bearing and screw cylinder plug down into cylinder body, using care not to damage O-ring or secondary cup. Tighten plug firmly, using Spanner Wrench J 5794 (fig. 9-22).

- With housing gasket placed on hydraulic cylinder so that one notch is at vent hole, install cylinder housing with two large holes for air cleaner on the same side as head nut; install four nuts and tighten securely.

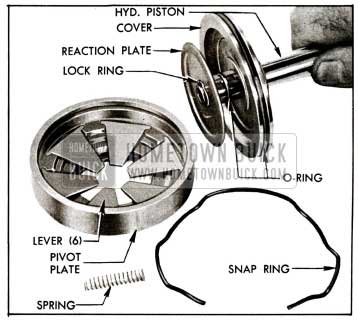

- Install new O-rings on hydraulic piston and the reaction cover, lubricating both O-rings and the bore of cover with silicone grease. Install piston reaction plate with concave side of rim toward shoulder of piston and install lock ring. Slide cover over piston with concave side toward reaction plate, using care to avoid damaging O-rings.

- Place the six reaction levers in their slots in pivot plate. Install hydraulic piston and cover assembly in pivot plate and install snap ring. Install new rubber seal in groove in small end of pivot plate and lightly: coat seal with silicone grease.

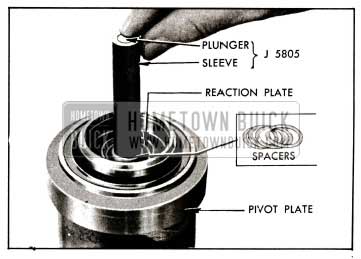

- Check for the number of spacers that may be required for proper location of the valve reaction plate, as follows:

- Support pivot plate in 3″ pipe with hydraulic piston downward so that the piston reaction plate rests against the cover and all levers rest on the plate.

- Center the valve reaction plate on reaction levers with rounded side of rim against levers.

- Install Spacer Gauge J 5805 on reaction plate so that long end of plunger extends through to rest on upper end of hydraulic piston, then note whether upper ends of gauge plunger and sleeve are at same level. Any slight difference in level may be felt with a finger. See figure 9-24.

1955 Buick Gauging for Selective Spacers

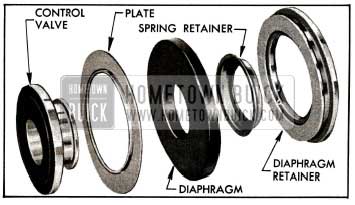

1955 Buick Control Valve and Diaphragm Disassembled

1955 Buick Position of Piston in Housing

I have a 1955 Buick super with a brake problem as follows: As so as the car is started the brake pedal goes without touching to the floor? I have drove the car and had plenty brakes but had no power assist, I found lines that had holes in them and repaired so now I have more vacuum but pedal goes down , not sure it has applied braking at this point since its on lift but seems like it would, the pedal travels from its high to about gas pedal height? And suggestions would be appreciated.