SECTION 10-H 1955 BUICK SIGNAL SYSTEMS

10-52 1955 BUICK HORNS AND CONTROL CIRCUIT

1955 Buick Horns and Relay

Two Delco-Remy electrically operated vibrator type horns are mounted in front of the radiator. Both 1955 Buick horns are operated simultaneously by a horn relay which is controlled by the horn button on steering wheel. The left hand horn is high pitched (380-400 cycles) and the right hand horn is low pitched (302-323 cycles), so that together they produce a pleasing blended tone.

The 1955 Buick horn relay is an electrical switch which closes the circuit between the battery and the horns when the 1955 Buick horn button is pressed, and opens the circuit when the button is released. The relay permits control of the horns with a small amount of current passing through the horn button contacts. The high current required by the horns would cause arcing and burning of these contacts.

When the 1955 Buick horn button contacts are closed, a small amount of current flows through the relay winding to ground at the horn button. This magnetizes the relay core, which attracts the flat steel relay armature. The armature has a contact point which makes contact with a stationary point to close the horn circuit. When 1955 Buick horn button is released, current stops flowing through relay winding so that the core loses its magnetism; the armature spring then causes contact points to be separated.

1955 Buick Horn Buttons

The 1955 Buick horn button used with the Series 40 standard steering wheel has a cap with a rubber retainer in its rim which snaps over the rim of a contact cup mounted in the wheel hub. The cap may be pried out with a thin bladed tool and the contact cup and other parts may then be removed by removing the attaching screws and insulating spacer bushings.

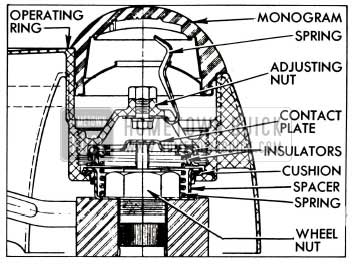

The 1955 Buick horn button used with the Deluxe steering wheel has a large operating ring mounted over the wheel hub and spokes. To remove the operating ring, (1) pry out the monogram which is held by the prongs of a retaining spring, (2) unscrew and remove the adjusting nut, (3) remove the contact plate and spring, with insulators, (4) remove steering wheel nut, (5) remove operating ring with cushion and contact spacer. See figure 10-65.

1955 Buick Horn Operating Ring Installation

Install operating ring by reversing the procedure for removal. The steering wheel nut is self-locking and does not require a lockwasher. When the contact adjusting nut is being installed, turn it down until contact is made and 1955 Buick horns blow, then back nut off 1/2 turn to provide proper clearance between contact plate and spacer.

Adjustment of 1955 Buick Horns

When 1955 Buick horns fail to blow first check wiring circuit (par. 10-12, c) before attempting to adjust horns. If 1955 Buick horns are at fault, or tone is poor, adjust each horn for specified current draw as follows:

- Remove 1955 Buick horn from car and remove the back shell, which is crimped over the collar at four points.

- Inspect air gap between armature and core for steel burrs or other foreign matter; clean out if present. This may correct the trouble. If it does not, proceed as follows:

- Connect an ammeter in series with the horn and a fully charged 12-volt battery to measure the current draw when horn blows. Current draw should be as follows:

Left (high note) horn – 9.5 Amps. min.

Right (low note) horn – 10.5 Amps. min.

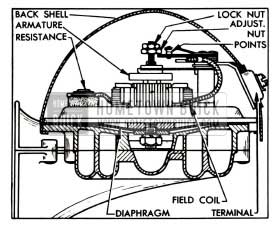

- Adjust to specified current draw, if necessary, by loosening lock nut and turning contact point adjusting nut clockwise to decrease or counterclockwise to increase current draw. See figure 10-66.

1955 Buick Horn Contact Point Adjustment

This adjustment is very sensitive, and adjusting nut should not be moved more than one-tenth turn at a time, then locked with nut each time before trying the horn.

Increasing the current draw increases the horn volume. Too much current will produce a high cut-in voltage, which will cause a sputtering sound and may cause horn to stick in cold weather.

- After each 1955 Buick horn has been adjusted individually, sound both horns together to check for proper blend of tone.

- After horn adjustment is completed install the back shell. Make sure that back shell is seated against horn collar all around, then crimp tangs of shell over collar at four points.

- When 1955 Buick horns are reinstalled, connect a voltmeter between each horn terminal and ground to check voltage when horns are blown. This should be at least 7 volts.

10-53 ADJUSTMENT OF 1955 BUICK HORN RELAY

Three checks and adjustments are required on the 1955 Buick horn relay: air gap, point opening, and closing voltage. These should be made in the following order:

- Remove 1955 Buick horn relay from car then remove relay cover.

- Push relay armature down until contact points just touch, then check air gap between armature and end of core using feeler gauges. Air gap should be .014″. Adjust gap to .014″, if necessary, by bending the lower point support. See figure 10-35.

- With armature free, check contact point opening, using feeler gauges. Point opening should be .025″. Adjust opening to .025″, if necessary, by bending the upper armature stop. See figure 10-36.

- Connect the positive terminal of a 12-volt battery to the battery (middle) terminal of horn relay.

- Using a variable rheostat of 10 ohms minimum and a capacity of 2 amperes, connect one lead to the negative post of battery. Set rheostat to provide full resistance, then connect the other lead to the “S” terminal of relay.

- Connect a 12-volt test lamp between negative post of battery and the “H” terminal of relay.

- Connect positive lead of low reading voltmeter to the battery (middle) terminal of horn relay and connect negative lead of voltmeter to the “S” terminal of relay.

- Slowly decrease resistance until the test lamp lights, note the voltmeter reading, then turn rheostat to full resistance. Closing voltage should be 5.5 to 7.5 volts.

- If closing voltage is not within specified limits, bend the armature spring post as required. Bend down to increase closing voltage or bend up to decrease closing voltage. See figure 10-37.

- After proper closing voltage is obtained, install relay cover. Install relay on car and connect wires as shown in wiring circuit diagram in Section 10-J.

10-54 1955 BUICK DIRECTION SIGNAL LAMPS AND SWITCH

1955 Buick Direction Signal Lamps and Indicators

The 1955 Buick front direction signal light is produced by the 32 CP filament in the bulb mounted in the front parking lamp. The 1955 Buick rear direction signal light is produced by the 32 CP filament of the 32-4 CP lamp bulb in the combination tail, stop, and direction signal lamp on each rear fender.

When the 1955 Buick ignition switch is turned on and the direction signal switch is manually operated to indicate a turn, the front and rear signal lights flash on and off on the side of car for which a turn is indicated. The flashing of signal lights is- caused by a Tungsol flasher which is connected into the proper signal light circuit by contacts made in the direction signal switch when switch is set for a turn.

When the 1955 Buick direction signal lights are flashing, a signal indicator bulb on instrument panel also flashes, producing a small arrow of green light to indicate the direction for which the signal has been set.

1955 Buick Direction Signal Switch Operation

The 1955 Buick direction signal switch and its operating mechanism are enclosed in a switch housing on the steering column just below steering wheel.

The switch is operated by a lever projecting from the left side of switch housing. Moving the control lever clockwise sets the switch to indicate a right turn and moving lever counterclockwise indicates a left turn.

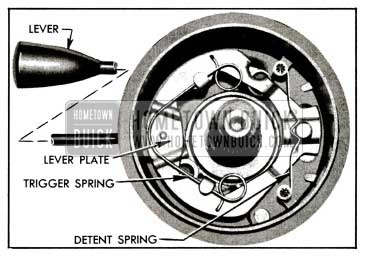

The 1955 Buick control lever is threaded to screw into a stub shaft anchored to a plate in switch housing which operates the switch. The stub shaft fits into a recess in the housing to provide a bearing or pivot point for the lever and plate. A groove in right side of the lever plate engages the bakelite handle of the switch which is mounted in the lower side of housing below the lever plate. A detent spring mounted in the housing bears against a roller mounted on the lever plate to hold the plate in whatever position it may be set. Bosses in the housing provide stops for the plate when set for either turn. See figure 10-67.

1955 Buick Direction Signal Switch

The trip mechanism for returning the switch to the “off” position after a turn is completed consists of a trigger spring on the lever plate and two switch centering pins on the steering wheel hub. The pins extend down through the lever plate, but when the switch is in the “off” position the lever plate is centered so that the pins cannot contact the trigger spring as the steering wheel is turned.

When the control lever is moved clockwise to set the switch for a right turn the lever plate is moved down, thereby moving the switch handle down and also bringing the upper loop of the trigger spring into the path of the centering pins. As the steering wheel is turned right and a centering pin contacts the trigger spring the spring yields to permit the pin to pass without interference. As the wheel is turned left at completion of the right turn, the centering pin pushes the loop of trigger spring against a stop on the lever plate, and this forces the lever plate and switch back to the “off” position.

A similar action but in the opposite direction takes place when the switch is set for a left turn. If the switch is erroneously set to indicate a turn in one direction and the turn is made in the opposite direction, the opposite centering pin will contact the trigger spring and return the switch to the “off” position as the wrong turn is started.

Replacement of 1955 Buick Signal Switch Parts

- Remove 1955 Buick steering wheel (par. 8-5).

- Set 1955 Buick signal switch for a right turn, remove the two switch housing attaching screws, loosen clamp where wiring harness emerges from column jacket, then lift housing assembly up over steering shaft.

- Remove detent spring, unscrew control lever (has two flats near housing for wrench), then push against lower end of stub shaft to remove lever plate from switch housing.

- If switch and wiring harness require replacement, disconnect wires from fuse block under the cowl and carefully pull harness out of steering column jacket.

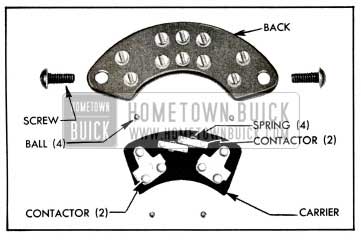

- Lay switch housing flat on bench, remove switch attaching screws, switch back with wiring harness, carrier with contactors, and the four small steel balls. See figure 10-68.

1955 Buick Signal Switch Parts

1955 Buick Direction Signal Lamp Circuits

Since the 1955 Buick direction signal lights are independent of the headlamp lighting switch and thermo circuit breaker, the wiring circuits are protected by a “Direction Signal” fuse on the fuse block under the cowl. The Tungsol flasher is also mounted on the fuse block, which serves as a terminal block between the signal switch and the chassis wiring.

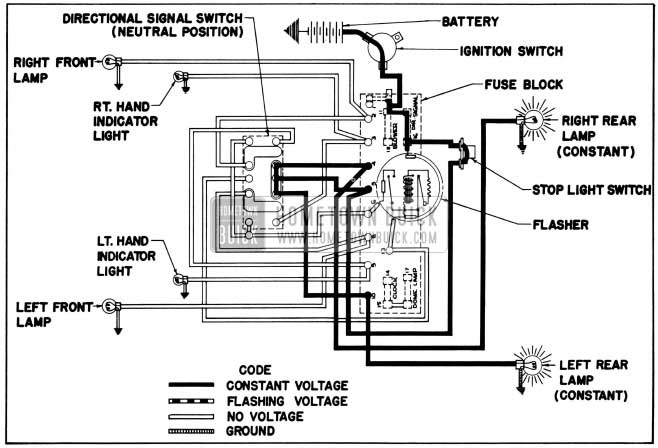

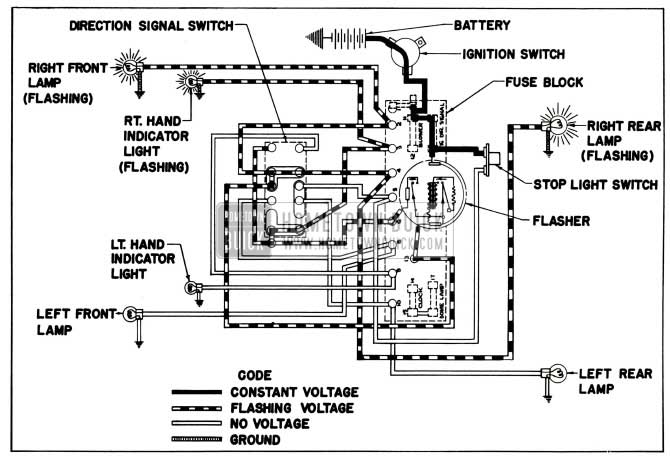

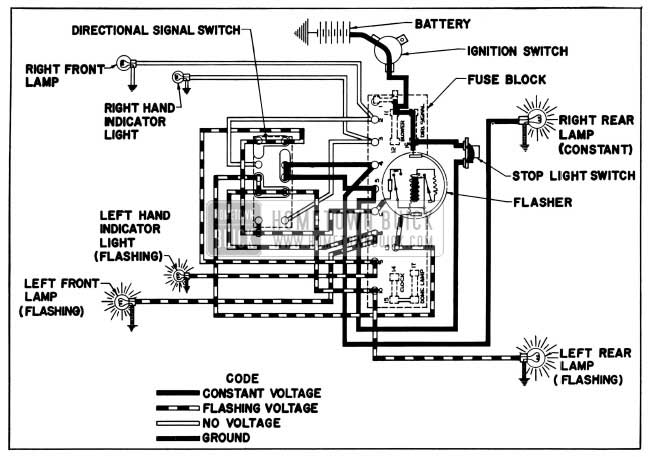

Figures 10-69, 10-70, and 10-71 show the 1955 Buick direction signal circuits when signal switch is set for No Torn, Right Turn, and Left Turn. 1955 Buick direction signal switch wiring is also shown in the 1955 Buick chassis wiring circuit diagrams in Section 10-J.

1955 Buick Direction Signal Lamp Circuit Diagram-No Turn Indicated

1955 Buick Direction Signal Lamp Circuit Diagram-Right Turn Indicated

1955 Buick Direction Signal Lamp Circuit Diagram-Left Turn Indicated

Hello, I have a oldsmobile 1955 with a deluxe steeringwheel there must be some parts missing between wheel and the switch, could you help in some way, thank you. john