1953 Buick Air Conditioner Cycle of Operation – Cooling

Here we see a schematic arrangement of all the components.

Assuming that the control switch is “ON,” the thermostat is calling for refrigeration, and the engine and compressor are operating, this is what takes place:-Low pressure vapor is compressed by the compressor to high pressure vapor and then discharged into the con denser. In the condenser the vapor changes from a high pressure vapor into a high pres sure liquid. The liquid then flows into the receiver under pressure through the check valve.

The high pressure liquid leaves the receiver under pressure through a tube extending near the bottom of the receiver then through a shutoff valve and the high pressure line which connects to the sight glass. Then the liquid passes through the dehydrator-filter and into the high pressure connection of the expansion valve. At the orifice of the expansion valve, the high pressure liquid changes to a low pressure liquid, and enters the cooling coil.

Heat enters the conditioning unit housing from the passenger compartment and from the outside by the action of the blowers and some leaks through the insulation of the housing it self. Because the cooling coil is colder, some of the heat passes through the refrigerated tubes of the coil into the liquid refrigerant. This absorption of heat causes the liquid to vaporize and the vapor under comparatively low pres sure through the low pressure line to the compressor.

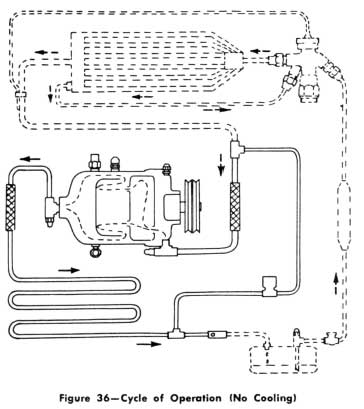

1953 Buick Air Conditioner Cycle of Operation – No Cooling

1953 Buick Cycle of Operation – No Cooling

In the foregoing explanation we described the cycle of refrigeration when cooling was required in the car, under which conditions the solenoid by-pass coil was energized and the by-pass line was closed. If there is no requirement for refrigeration, the solenoid by-pass coil will be de-energized by either the “ON OFF” switch or thermostat and the solenoid valve by-pass line will be open. Opening of the by-pass line reduces the pressure on the inlet side of the check valve causing it to close. Thus, the refrigerant vapor is by-passed back to the compressor. This action stops refrigeration in the cooling unit.

The lubrication of the internal parts of the expansion valve is a fairly simple matter. This is caused by the fact that Freon-12 and oil like each other so well that they “go around together.” They will mix together just like gasoline and oil. Even the Freon-12 vapor in a sys tem will carry globules of oil. As the Freon-12 travels through the system in either a vapor or liquid state, it is carrying enough oil picked up in the compressor oil reservoir to keep the moving parts of the valve lubricated. As previously explained, the compressor is lubricated by the action of the oil pump and the oil saturated vapor.

This completes the Cycle of Operation and brings us to the next section of our booklet: “Factors In Handling Freon” and “Use of the Leak Detector.”

Leave A Comment

You must be logged in to post a comment.