This section of the 1950 Buick Service Bulletins is about 1950 Buick Rear Axle Maintenance. Page 37 of the 1949 BPS Abridged Edition describes improved service differential gears available for 1940-41-42-H42 Series 40 and 50 cars.

The Parts Department has now replaced the 1393200 gearset (4.454-1 ratio with case) with the 1393765 gearset which is also supplied as a replacement for the 1393198 (4A54-1 ratio less case) set.

Installation of this improved gearset will also require the differential carrier reworking operation described in the abridged BPS reference.

In the past we have devoted several articles to correction of oil seepage from the 1950 Buick rear axle into the torque tube or propeller shaft and, in the case of a defective or incorrectly installed spline seal, into the transmission. As pointed out, this condition may cause damage to the Dynaflow, reverse bind or chatter in the Dynaflow, roughness similar to that caused by propeller shaft “out-of -balance'” or premature 1950 Buick rear axle gear and bearing wear.

In view of the possible serious consequences of this leakage condition the factory has made every effort to provide the field with up-to-the minute service information.

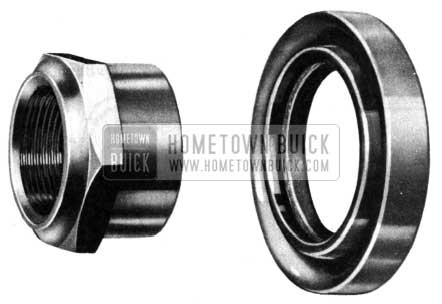

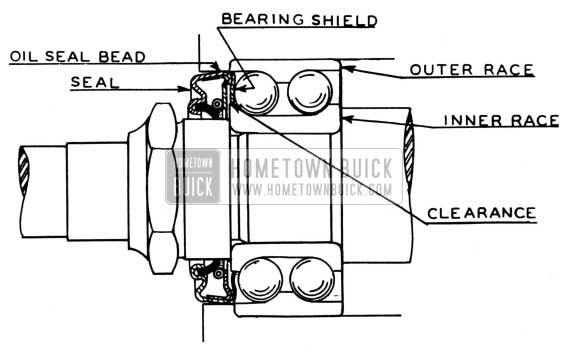

Buick Parts Warehouses now have available a new type pinion bearing seal and nut (see Figure 27) designed to positively control escapage of axle lube into the torque tube, when installed according to instructions.

1950 Buick Rear Axle Pinion Bearing Seal

The seal may be used on all models 1940 through 1950 except 1940 Series 80 and 1940, 41 and 42 Series 90 jobs. Installation of the seal and nut, supplied as Group 5.445, Part No. 1393999, Kit, 1950 Buick Rear Axle Pinion Bearing Oil Seal, is made as follows:

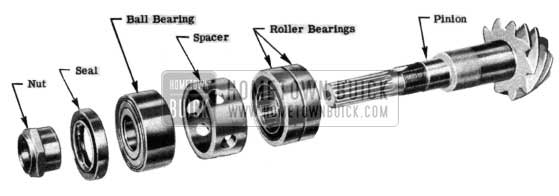

- Remove the propeller shaft and pinion assembly. Check the shaft spline seal, for deformation caused by incorrect location, as outlined in the 1949 BPS Abridged Edition, page 33.

- Remove the propeller shaft from the pinion, marking the position of the shaft so that it may be reinstalled in the same position.

- Remove the production pinion bearing nut.

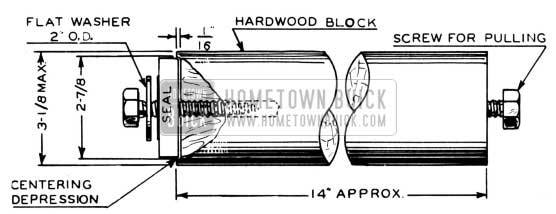

- Make a trial installation of the oil seal in the carrier bore, using a driver made up locally to specifications shown in Figure 28).

1950 Buick Rear Axle Pinion Oil Seal

The seal is placed on the end of the driver, secured by the screw and washer, and driven lightly into the carrier. Do not use excessive force.

1950 Buick Rear Axle Pinion Bearing Seal Adjustment

In this case, assembly may be made without special fitting.

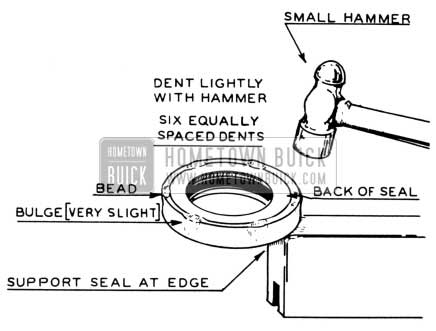

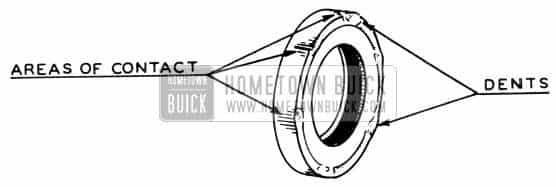

- If the seal slips easily into the bore and shows no scratches, or widely spaced scratches, it must be fitted and sealed. This fitting is accomplished by denting the bead on the rear face of the seal in six locations (Figure 30), bulging the outer retainer sufficiently to increase the diameter .005″.

1950 Buick Rear Axle Pinion Oil Seal Adjusting

CAUTION: Use extreme care in denting the bead so that original bead height is retained over most of the seal. This bead spaces the seal from the front bearing and prevents interference. (Figure 31)

1950 Buick Rear Axle Pinion Seal Bearing Shield

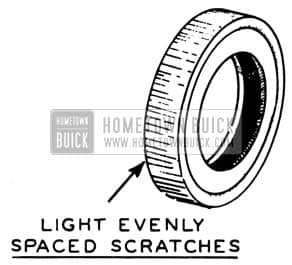

Make another trial installation of the seal, making sure that the seal seats snugly in the bore. When removed the seal O.D. should bear scratches as indicated in Figure 32.

1950 Buick Rear Axle Pinion Bearing Seal Areas of Contact

1950 Buick Rear Axle Prop Shaft and Pinion

The oil seal will be pushed into correct position in the carrier bore by the shield on the front pinion bearing.

The new oil seal is designed so that pinion shimming may be checked, and the propeller shaft and pinion assembly installed or removed in the usual manner.

Leave A Comment

You must be logged in to post a comment.