PRODUCT REPORT INFORMATION

When submitting product reports on any of the component parts of the car, our Engineering and Inspection Departments would like to have more complete information on the parts in question.

When reporting clock failure, the make (Borg or New Haven) should be mentioned. The clocks can be easily identified by observing the manufacturers name stamped on the back. Also when reporting carburetor or starter switch failures, the make as well as the model should be so stated.

Our Engineering and Inspection Departments have requested that whenever submitting product reports on porous casting of either the block or head, to include the date of the casting as well as the car serial number.

The date of the casting block is located on the flywheel housing along side of the distributor and the casting date of the cylinder head may be found in the center of the head under the rocker arm cover. They have also asked when submitting Dynaflow reports to include the Dynaflow number which is stamped in the lower edge of the reaction shaft flange directly to rear of the high accumulator. This will provide a method to determine if changes are effective and will assist in correcting any out-of-line conditions that may arise.

ANTI-FREEZE MIXING

Numerous requests have been received regarding the results of mixing various types and brands of anti-freeze solutions, volatile (methanol) and non-volatile (ethylene glycol). No chemical reaction will result from such a mixture, but an accurate reading on a hydrometer cannot be obtained since both types have a different, specific gravity and temperature reading. All Buicks shipped from the factory during the winter months are equipped with a 160° thermostat, using a volatile (methanol) type anti-freeze, and a sticker is placed on the windshield indicating same. If a non-volatile (ethylene glycol) type solution is used, the higher limit 180′ thermostat may be used to improve car heater performance. Should an owner desire to change the type anti-freeze solution in his car, (volatile or non-volatile) he should have the radiator, engine block, and heater hoses completely drained before doing so.

DOT FILMS

Since the inception of the Dealer Organization Training Program, several informative sound slide films have been produced which deal with service. Most dealers who subscribe to this program have taken full advantage of the films they have received and have held regular departmental meetings to review the films and discuss the subject presented. In some cases, however, due to lack of facilities or time, the films have not been presented to dealership personnel and we are submitting herewith a list containing the titles of all films produced to date so that dealers and Service Managers may be reminded of the subjects covered so far. Any dealership participating in the DOT program has received copies of each of the following:

No. – Subject

7 – “You’re The Dynaflow Doctor”

9 – “Company Manners”

10 – “Servicing Hydraulic Valve Lifters”

14 – “Servicing The Power Steering Gear”

15 – “Servicing The Rear Axle”

17 – “Servicing Buick Power Brakes”

18 – “Servicing The Stromberg 4-Barrel Carburetor”

19 – “The Man They Ask For”

54- 2 – “The Why and How of New Car Make-Ready”

54-11 – “Buick Air Conditioning System Diagnosis and Trouble-Shooting”

54-22 – “Little Things Mean A Lot”

55-2 – “On Center”

RETURNING AFA MATERIAL

Some dealers are returning warranty and policy material to their Zone M. R. Room by railway express and parcel post. Because of the high transportation charges when shipped in this manner, they should be shipped by truck or freight.

It is requested that in the future dealers return such material the cheapest way because credit for transportation charges will be based on the cheapest method of shipment from the dealers location to the M. R. Room.

All material must be properly tagged and should be returned in the shipping cartons in which the new parts were received from the warehouse.

KAR KLEEN APPLICATION

Whenever Kar Kleen solution is applied to nylon or other synthetic fabrics, the solution should be wiped at once and the fabric be dried rapidly in the sunshine or with heat lamps. Allowing nylon fabric to dry slowly could result in spotting of the material. Do not soak trim by using excessive solution.

Instructions on reverse side of label should be read thoroughly prior to using solution.

COOLING SYSTEM CONDITIONING

All Models

We have received numerous requests from the field for information regarding the advisability of permanent anti-freeze being left in the cooling system of Buick cars on a year around basis. Our Research Department advises that there is a possible hazard in the continuous use of permanent anti-freeze from one season to another. Used in this manner and under certain circumstances, the coolant will reach a high acid content and can damage the engine through corrosion. This corrosion can cause scale and sludge formations that will restrict proper cooling. Therefore, to prevent a condition of this type from occurring in Buicks, it is recommended that permanent anti-freeze solution be used for one season only and the cooling system be drained twice a year. For maximum protection, it is also recommended that “Buick Stop Leak and Cooling System Conditioner ”, Group 8.800, Part No. 981441 be added to the radiator.

In conjunction with a national Radio and TV program on the protection and preventive maintenance of cooling system, attached to this BPS Bulletin is a poster containing suggested service recommendations for draining, inspection, cleaning, etc.

Additional copies of this poster, as well as 8 1/2 x 11 duplicate copies, suitable for handout or mailing are available “free” of charge upon request. Please send request to:

Buick Motor Division Parts and Accessories Flint, Michigan, Att: Mr. Ray Ross

40 SERIES TIRES

In order to eliminate any misunderstanding on the correct wheels and tires used on 1955 – 40 Series cars, the following is submitted:

Wheel Size 15 x 5.50 Gr. 5.803 Part #1166537. Tire Size – Either of the following tire sizes may be used with the above wheel:

- 10 x 15 (Standard)

- 60 x 15 (Optional)

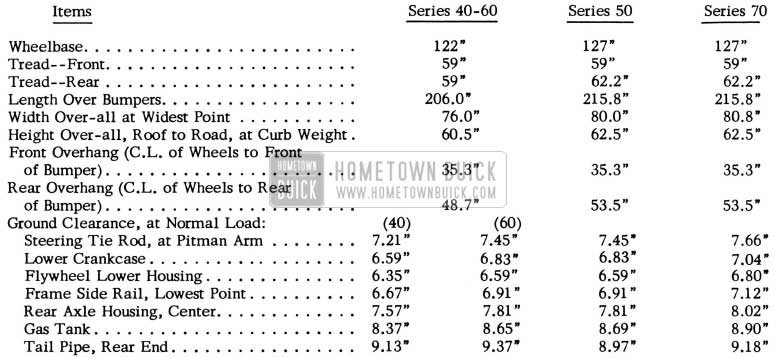

GENERAL SPECIFICATION

1955 Buick General Specification

Leave A Comment

You must be logged in to post a comment.