a. Lifter Bodies

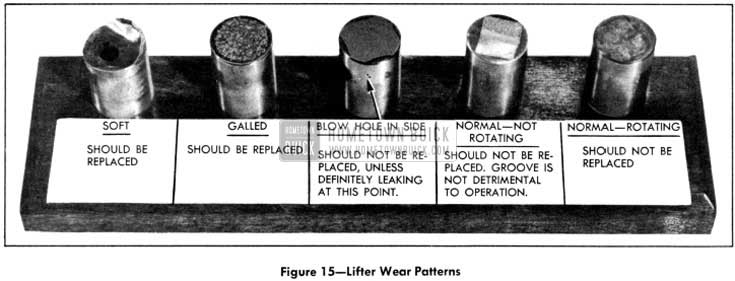

- Immediately following the removal of lifters from a job, they should be visually inspected for an excessively worn foot condition. Figure 15 illustrates five different conditions which will be encountered. Those lifters which are soft, spalled or have straight line wear in the lifter foot, which is rough or scored, should be discarded immediately. Straight line wear which is smooth is acceptable. Lifters with a spalled foot condition are not necessarily soft. During the casting of the body it is possible for the metal grain structure to vary so that the hardness test will be acceptable, yet the lifter foot will spall.

Whether or not a lifter rotates has no effect upon its performance. Certain design features such as the centerline of the cam lobes being laterally off center approximately 1/16″ with the centerline of the lifter tend to promote rotation, but manufacturing tolerances of the lifter body will sometimes counteract this offset, preventing rotation.

1951 Buick Lifter Wear Patterns

- The outer wall of the body should be inspected for scoring and blow holes. The wear pattern which is evident on the outer wall just up from the bottom of the lifter is caused by the thrust created at this point by the cam lobe striking the lifter. This is not injurious to a lifter unless it is grooved or scored. Unless the blow hole is completely through the body, which would allow oil leakage, the body is satisfactory.

- Visually inspect the body bore for scoring and to make sure it is clean.

b. Plungers

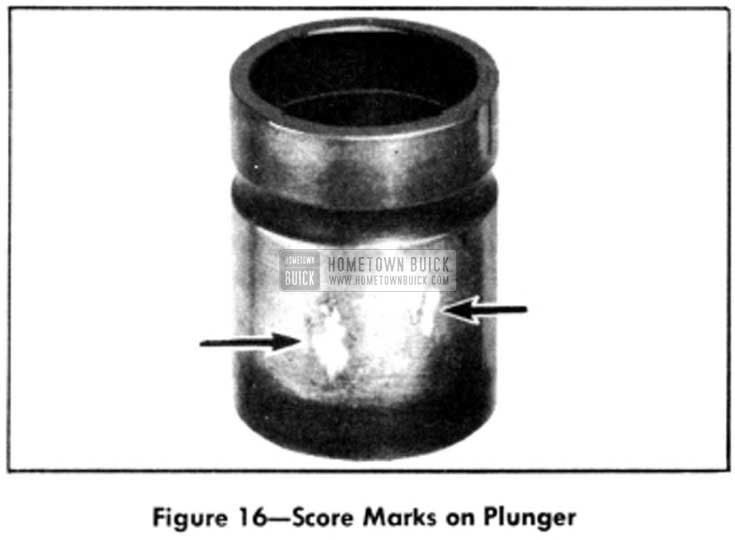

Inspect the O.D. of the lifter plunger for scoring or varnish and the ball seat for imperfections. After the plunger is cleaned, the plunger wall should be free from any scratches or scoring which can be felt with a fingernail. Color has no effect on the plungers performance as long as the surface is smooth. Score marks with a frosty finish which are rough and approximately 1/16″ diameter or larger in size will not hold lubrication when hot. They will cause the plunger to seize, but will release when cooled and function normally until they become hot again. Plungers of this type should be discarded along with its matching body.

1951 Buick Score Marks on Plunger

The criterion for determining an unsatisfactory plunger is, “anything which feels rough to the fingernail should be discarded”, with one exception. The slight edge which may sometimes be felt that divides the lower portion of the plunger, which does not contact the body wall, from the portion of the plunger, which does contact the body wall, is permissible. However, if the dividing line is sharp or burred, the plunger and body should be discarded.

c. Ball Retainer

The ball retainer should be inspected for cracks and brinelling between the two holes in the bottom. A slight shiny dot between the holes is common to all retainers after use, but any pounding out of this surface is not acceptable and the retainer should be replaced.

d. Check Ball

Irregularities on the ball surface which are not visible to the eye such as nicks, indentations, out of round or lint can cause a lifter to be noisy intermittently. For this reason it is recommended that whenever lifters are cleaned that the ball be replaced with a new one.

e. Push Rod Seats

Inspect the push rod seat to make sure the oil feed hole has been drilled through. If the area where the push rod seats is rough or cut up in any way, replace it with a new one.

f. Springs

As of this date, all springs which were returned to the factory as being faulty were checked and found to be within limits. It is apparent that when the springs were replaced something else was done to correct the noisy condition such as cleaning out a minute particle of dirt or metal from the lifter. All tests up to the present time indicate that replacement of lifter springs is not necessary.

Leave A Comment

You must be logged in to post a comment.