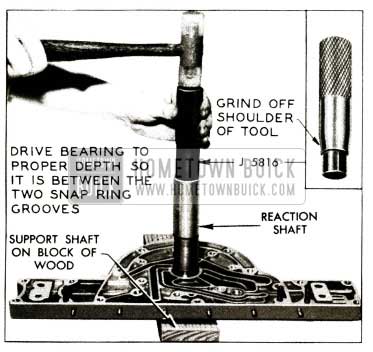

TOOL MODIFICATION

Reaction Shaft Bushing Installer Tool

The Dynaflow reaction shaft bushing installer, J-5816 must be modified as shown in Fig. 138.

1956 Buick Reaction Shaft Bushing Installer Tool

The relationship between the end of the bushing and the end of the reaction shaft has been changed; therefore, the shoulder on the tool prevents the bushing from being driven deep enough. To overcome this difficulty, grind off the shoulder and then drive the bushing deep enough so that it is located between the two snap ring grooves in the inside of the reaction shaft.

BEARING REMOVER TOOL REWORK

As previously advised in Special Service Letter, Dealer No. 169–dated January 18, 1956, and again on page 91 of BPS Bulletin 2.401, dated February 10, 1956, J-6191, Wheel Bearing Remover Plate, will eventually break in use if not reworked.

Kent-Moore will remachine and reheat-treat your J -6191, stamping it J -6191-A without charge. Mail it to Kent-Moore Organization, Inc., 1501 S. Jackson Street, Jackson, Michigan.

Any unreworked J -6191 tools returned broken after April 30, 1956, will not be replaced free of charge. Kent-Moore will continue rework of unbroken tools without charge and their normal 1 year warranty will apply to J -6191-A (reworked).

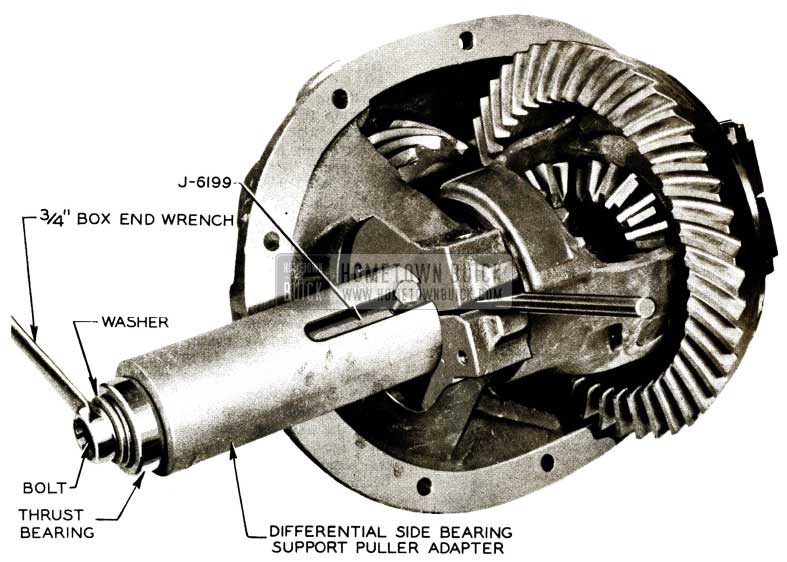

DIFF. SUPPORT PULLER ADAPTER

It has been brought to our attention that when removing the 1956 differential bearing supports, the slide hammer and special tool, J -6199, at times do not supply adequate force to remove the bearing supports. A new tool, differential side bearing support puller adapter (see Fig. 139) which can be made locally or purchased from Kent-Moore, has been developed and will provide adequate force to remove these supports.

1956 Buick Rear Axle Bearing Remover Tool

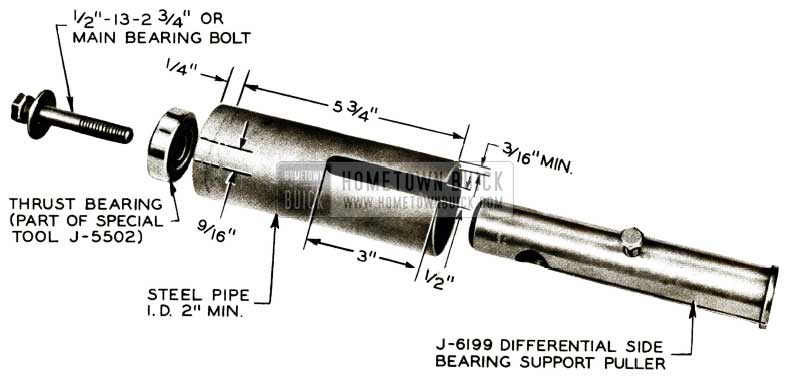

The new tool (see Fig. 140) can be made of steel pipe that is 5 3/4″ long and with a minimum inside diameter of 2 ”.

1956 Buick Rear Axle Jack J-3222

The pipe thickness should be held to a minimum of 3/16″. The tool has a 1/2″ slot, 3″ long, cut in the side to allow the bolt on support puller, J -6199, to slide up into the adapter when removing the bearing supports. A piece of 1/4″ plate with a 9/16″ diameter hole is welded onto the top of the steel pipe to withstand the tremendous force which is being exerted when removing the bearing supports. To minimize the torque on the top of the new tool, a thrust bearing is used which is part of special tool, J-5502, pinion and drive shaft remover and replacer. A main bearing bolt or a 1 /2″ 13-2 3/4″ bolt is used to apply the pulling force.

It will be approximately 60 days before Kent Moore will have the adapter in stock. Detailed information on the price and a firm delivery date will be published when available.

When using the tool as shown in Fig. 139, if the support does not break free until a reasonable force is applied to the bolt, it is recommended that one ball peen hammer be placed against the case in the area of the bearing and then hit solidly with a second hammer. This jarring action will cause the support to break loose from the bearing inner race.

AXLE JACK CHANGE

The present rear axle jack, J -3222, which is used to move the rear axle assembly back to facilitate the removal of the Dynaflow transmission is not satisfactory for use on the 1956 product. The overall length of the jack is too short which causes it to fall apart. To overcome this difficulty, a new detail for the rear half of the jack has been developed. Complete information as to availability and price will be published as soon as possible.

NEW PRESS PLATE HOLDER

During the course of the 1956 essential tool program, a serious problem developed with J -6274, press plate holder. Use of this tool in Product Schools indicated that material and heat-treat were not adequate for the job.

In order that you might adequately service the 1956 product without undue delay, Kent-Moore Organization completed these tools and shipped them with a tag indicating a replacement would be shipped without charge as quickly as possible.

In the meantime it became apparent that a larger press plate holder for future applications might well be desirable. To anticipate this future need, KentMoore developed J -6407, press plate holder, to replace the defective J-6274. See Figure 141.

1956 Buick Press Plate Holder

This new holder is not only heavier and stronger, but it has a considerably larger opening to handle larger future components. To adapt the larger opening to the present tools in the 1956 essential tool kit, such as J -6377, Figure 141, it includes the adapter ring, J -6407-2. This increase in the tool opening should eliminate the necessity of purchasing a larger tool at a later date. The new tool will list for $19.35 as compared to the list of $8.95 on J-6274. In spite of this design change and a substantial difference in price, Kent-Moore’s policy of providing satisfactory tools dictates that a J -6407 be shipped free of charge to each dealer who purchased the J-6274.

It is anticipated that shipment of the J -6407 tools will start about the middle of February. All shipments will be made to the same name and address as the 1956 Tool Program unless Kent-Moore is given other instructions. In the event there are changes, mail complete details to Kent-Moore Organization, Inc., 1501 S. Jackson Street, Jackson, Michigan. This notification will eliminate delays in receiving the new J -6407.

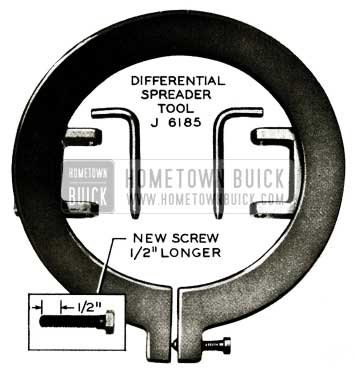

TOOL J.6185 CORRECTION

Reports indicate that m some cases the screw in tool J -6185, Figure 142, is not long enough to properly spread the tool.

1956 Buick Differential Spreader Tool J-6185

To overcome this difficulty, a new screw, Figure 142, which is l/2″ longer will be mailed at no cost to each dealer who purchased the 1-6185. The new screw will allow the tool to be spread the required distance.

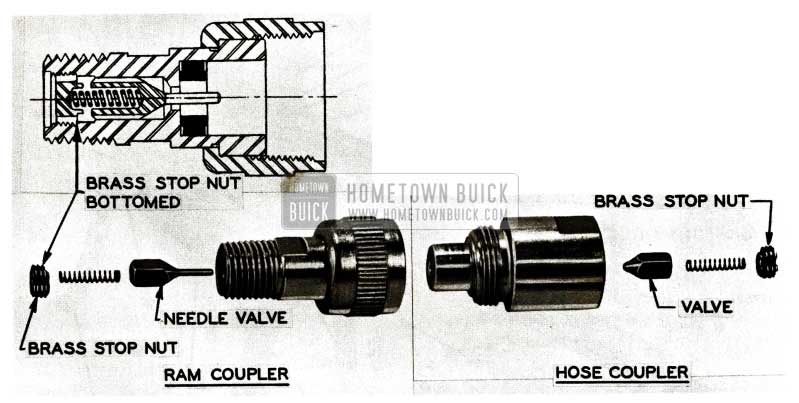

POWER PUMP AND RAM TOOL CORRECTION

Reports have been received indicating that some of the power pumps and rams, 1-6207 and 1-6180, are not operating satisfactorily. The reports state that the ram will travel a short distance under load and then will suddenly act as if the ram has jammed and excessive pressure applied to the pump handle will not break it loose. If the valve is opened on the pump and the operation repeated, the same thing may or may not happen again.

It has been determined that the trouble is in the hose and ram coupler. In effect the valve in the hose end of the coupler is closing because the valve stem in the rain end of the coupler is not holding it open when the entire system is under pressure.

To overcome this difficulty, remove the coupler from the ram. Figure 143 shows the ram coupler, the hose coupler and a line drawing of the ram coupler. It will be found that the brass stop nut has backed out, allowing the needle valve to drop back so far that it only partially unseats the valve in the hose coupler. To correct the difficulty, turn the brass stop nut all the way in until it bottoms and then lightly stake it in place.

Defective pumps and rams under warranty may be returned to Kent-Moore or to the nearest Blackhawk Authorized Service Station

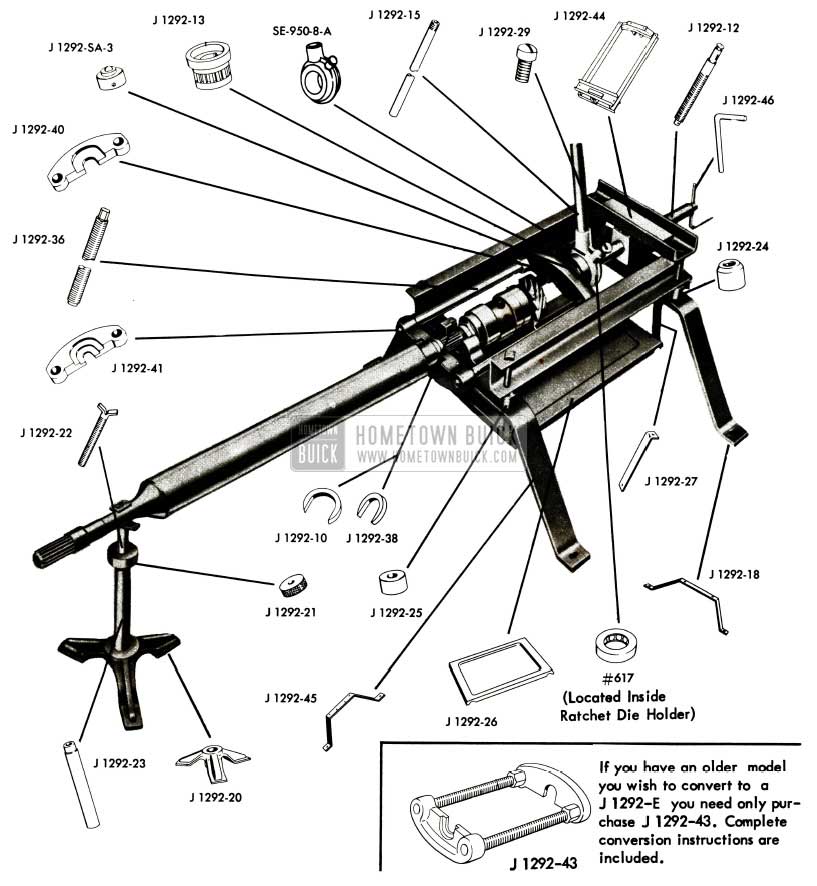

PINION PRESS CANCELLATION

The J -1292-E, rear axle pinion press, has been discontinued and replaced by J-6215. (See article on this page.) Service parts for the J-1292-E, press, will be carried by Kent-Moore. To assist in ordering replacement parts, Figure 144 has been developed which shows all of the available details. The prices now in effect for each part are as follows:

1 -1292-SA-3 – 6.95

1-1292-10 – 3.40

1-1292-12 – 9.55

1-1292-13 – 7.90

J-1292-15 – 3.35

1-1292-18 – 7.65

1-1292-20 – 3.50

J-1292-21 – 2.55

1-1292-22 – 3.55

J-1292-23 – 2.20

J-1~92-24 – 1.35

1-1292-25 – 1.50

J-1292-26 – 4.20

1-1292-27 – .95

1-1292-29 – .50

J-1292-36 – 5.70

J-1292-38 – 3.40

1-1292-40 – 9.25

1-1292-41 – 10.35

1-1292-43 – 32.00

1-1292-44 – 47.20

J-1292-45 – 8.30

1-1292-46 – 1.00

SE-950-8-A – 6.35

#617 – 1.05

PORTABLE LIFT EQUIPMENT

It has been brought to our attention that damage to the rear brake lines on 1956 jobs may result if care is not exercised in the use of portable lift equipment having U -shaped lifting pads which bear on the rear axle. It is, therefore, recommended that all such portable lift equipment be checked for possible interference between the U-shaped lifting pads and the rear brake lines. In cases where such interference may occur, extreme care must be exercised to avoid possible damage to the rear brake lines.

NEW REAR AXLE PINION PRESS

The J-6215, rear axle pinion press, replaces the discontinued 1 -1292-E, pinion press. The new press, 1-6215, using the hydraulic pump and ram released with the 1956 tool program, is both efficient and simple to use.

1956 Buick Power Pump and Ram Tool

J 1292-E SERVICE PARTS

This is a complete list of all available service parts. None other can be obtained.

1956 Buick J1292-E Service Parts

If you have an older model you wish to convert to a J 1292-E you need only purchase J 1292-43. Complete conversion instructions are included.

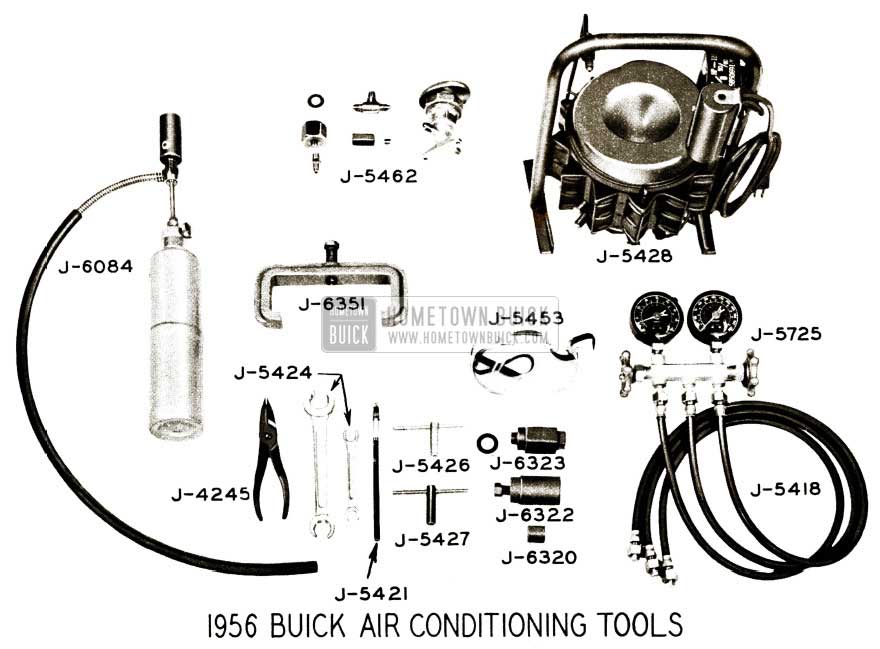

1956 BUICK AIR CONDITIONING TOOLS

1956 Buick Air Conditioning Tools

Leave A Comment

You must be logged in to post a comment.