ANTI-FREEZE OPTION

We have been advised that approximately February 1, 1956, permanent type anti-freeze will be available as option ”T” on dealer sales orders.

When orders are received requesting permanent type anti-freeze, the cars will be filled with 8.4 qts. which is equal to 44% anti-freeze by volume and will provide protection to -20° F. Permanent type anti-freeze will be available as an option all year around. To identify those cars equipped with permanent or methanol antifreeze, a warning tag (red for permanent and white for methanol) will be attached to the overflow pipe at top of radiator, instead of the warning sticker posted on the windshield.

It is important, therefore, when testing antifreeze, to refer to the warning tag to determine what type of anti-freeze has been installed.

DOW CORNING COMPOUND

We have been advised by the Dow Corning Corporation that the DC -4 Compound number has been changed to OC-4X and should be ordered under the new number. The lubricating quality and specification of the DC-4X is identical to that of the DC -4 and meets all the requirements as covered in BPS 2.359 dated January 15, 1954.

SUBMITTING PRODUCT REPORTS

Several requests have been published in past BPS bulletins regarding the information submitted on Product Reports. In a number of cases the product reports submitted are worthless because they do not give complete information. For example, when reporting carburetor difficulty, our Engineering Department would like to know what make of carburetor is involved. Likewise, when complaints on Dynaflow transmissions are reported, the transmission number should be shown.

It is very important to complete all the information requested on the Product Report in order to pinpoint the exact product, component or assembly that is causing the trouble. Therefore, when submitting product reports please include all pertinent information – model, year, mileage, make of part in question, and brief description of trouble and what was done to correct it.

WAXING EXTERIOR CHROME

We have been advised that effective January 23, 1956, all Flint built cars will have the exterior die cast chrome parts waxed with the exception of the grille. This will provide added protection against the elements for items such as hood ornament, grille frame, deck lid ornament, etc. All other assembly plants will do the same but will not be in effect until approximately January 25, 1956.

This waxing operation is not intended to be a lasting protection, but to protect the cars while they are in transit from the assembly plant to the dealer. If an owner desires additional protection of chrome parts, this can be accomplished by using Buick Chrome Preservative Gr. 8.800 Part #981164.

PREMIUM TIRE

Production 4-ply tires are used in working out Buick ride and handling. All tire companies market so-called premium tires which are generally superior to those used in production in anti -skid qualities, tire mileage, and in some cases puncture sealing.

Inasmuch as the ride, handling, and noise problems have been worked out on the basis of a standard tire, our Engineering Department is not in a position to advise the dealers how to correct customer complaints arising from the use of the so-called premium tires.

WHEEL SEAL

Numerous inquiries have been received regarding the wheel seal material covered in BPS 2.389, dated May 20, 1955, and BPS 2.400, dated January 20, 1956. The material referred to is now known as Seal All Wheel Seal and it is distributed by Allen Products Corp., Detroit, Michigan. This material is a liquid which is brushed on and dries in 10 to 15 minutes and does an excellent job of sealing air leaks in metal wheels. Openings up to 1/64” wide and 1/8” long may be sealed satisfactorily with this material. It is available in 1/2 pint, 1 pint, and 1 quart cans. In the event that the material cannot be purchased locally, it may be ordered directly from Allen Products Corp., 20450 Sherwood Ave., Detroit 34, Mich.

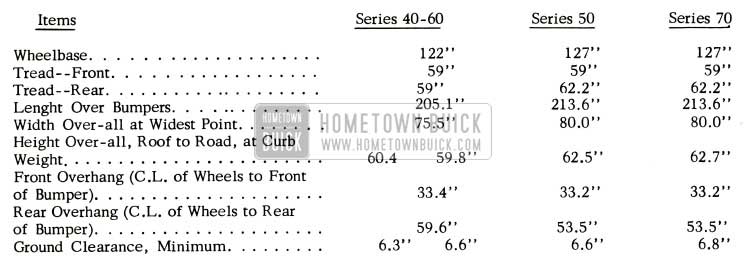

GENERAL SPECIFICATIONS

1956 Buick General Specifications

Leave A Comment

You must be logged in to post a comment.