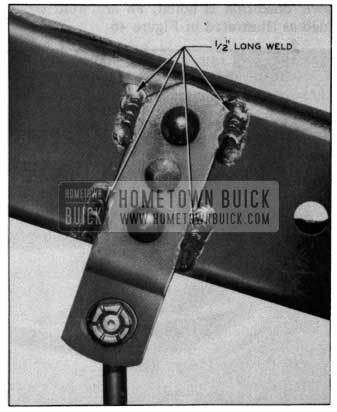

WELDING REAR SHOCK ABSORBER LINK FRAME BRACKET

1954 ALL SERIES

In some cases it has been reported that the rear shock absorber link frame bracket to frame rivets are loosening, thereby causing a knock at the rear of the car due to the action of the shock absorbers.

When this condition is encountered, it can be corrected by welding the bracket to the frame in four places (minimum 1/2″ long welds) at both rivet locations as shown in Figure 43.

1954 Buick Rear Shock Absorber Link Frame Bracket

Should a noise occur in the rear of the car we suggest you first check this bracket before attempting any other repair.

WHEEL CHECK POINTS

1954 WHEEL

A number of requests were made for the correct points for taking indicator reading of lateral and radial runouts of 1954 wheels. The correct points for checking are indicated in Figure 44.

1954 Buick Wheel Check Points

Both the steel and wire wheel are to run true laterally and radially within .045″ total indicator reading on a true running fixture.

NEW STEEL WHEEL

1954 MODELS

In order to facilitate production, a new Steel Wheel is being used which does not have the hub cap clips riveted to the wheel. Instead, this new Wheel has slots to accommodate newly designed clips, which can be inserted to retain the hub caps when they are used instead of wheel covers.

The new Wheel, Gr. 5.803, Part No. 1346203 will replace the present Wheel, Gr. 5.803, Part No. 1346202 for all service replacements. The Clips, Gr. 5.864, Part No. 1163410 for Motor wheels and 1166038 for Kelsey Hayes wheels should be ordered separately and used when hub caps are used.

The old style clips which were attached by rivets will still be serviced.

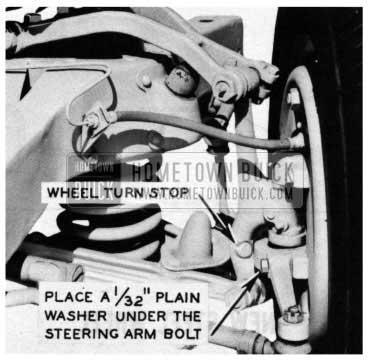

FRONT TIRES RUBBING ON FRAME

1954 SERIES 70

Some of the first production Buicks were shipped out with too much turning angle on the front wheels. This condition, if not corrected, will permit the front tires to rub the frame side rail upon a full turn. (metal to metal position of front suspension.) In cases where owners complain of tire rubbing, it will be permissible to install a 1/32″ thick plain washer under the bolt head of the rear steering arm bolt on both right and left sides. (See Fig.45)

1954 Buick Front Tires Rubbing on Frame

In order to install the washer, it will be necessary to remove the hub and drum assembly to gain access to the nut on the rear steering arm bolt.

The washer under the steering arm bolt head reduces the turning angle of the wheel enough to eliminate the tire from rubbing the frame on full turns.

IMPORTANT, ALL SERIES: It should be noted that a check for tire clearance should be made after

installing other than factory specified tires. Thus, extra heavy duty or safety tires such as Royal Masters or Double Eagle, etc. may not have proper frame clearance due to their greater size.

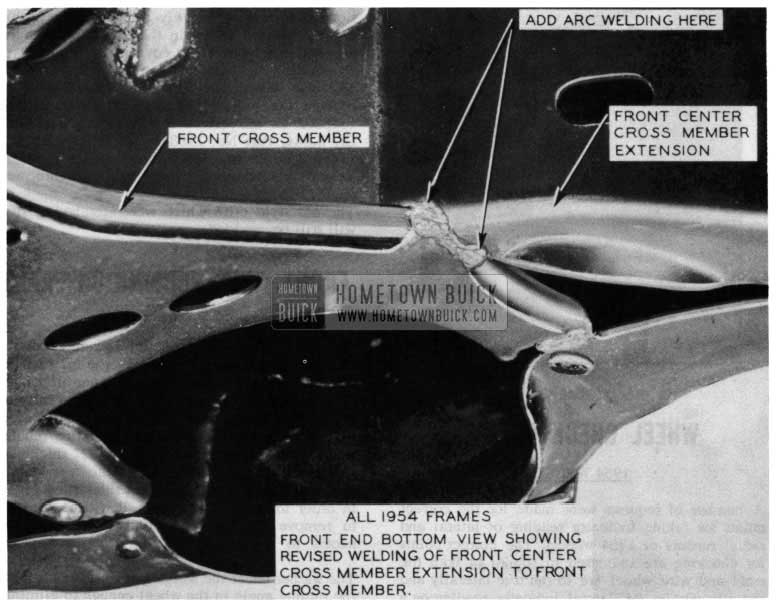

FRONT END SQUEAK, FRAME WELD

ALL 1954 SERIES

Some of the first 1954 Buicks developed a sharp front end squeak that was first thought to be in the front suspension. Subsequent investigation disclosed that the squeak was caused by a fracture in the weld at the junction of the front center cross member extension to the front cross member at the bottom. (See Fig 46)

1954 Buick Front End Cross Member

It is recommended that all new car “Make Ready” and “Lubricare” men be informed of this condition and advised to watch for it on all new cars. lf the above condition is noted, an arc weld should be added as illustrated in Figure 46.

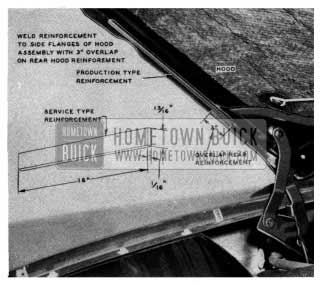

HOOD REINFORCEMENT

40-60 SERIES ONLY

To prevent buckling of early Series 40-60 hoods at the side flanges, a reinforcement was added shortly after production started. Parts warehouses stock however, may not necessarily have the reinforcement.

It is our recommendation that you examine your Parts stock of these hoods and see if they have the reinforcement. (See Figure 47)

1954 Buick Hood Reinforcement

If not, a reinforcement can be made from 1/16″ flat steel stock, as shown in Figure 47, and should be welded in position on each side of hood so as to have a three inch overlap on the hood rear reinforcement as shown in Figure 47.

BENDING REAR BUMPER

ALL 1954 MODELS

Some complaints of the rear bumper being bent on 1954 models were found to be caused by service men using the rear bumper for towing a motorcycle with the motorcycle clamp bracket installed in the wrong position.

To eliminate the possibility of bent bumpers, the clamp bracket should be attached as close to the outside of the left rear bumper guard as possible. If the clamp is placed between the guard and the end of the bumper, it is very easy to permanently crimp the face plate.

FRONT FENDER RATTLES

1954 MODELS

It may be possible for a rattle to develop at the front fender to fender reinforcement while driving on rough roads. Vibration starts the sheet metal of the fender to oscillate which causes slapping of the fender against the brace.

To overcome this condition, use a suitable shim such as a rubber pad, anti-squeak pad, impregnated felt, etc., as shown in Figure 48.

1954 Buick Front Fender

This pad should be placed between the fender and brace approximately three to four inches below the fender molding, and securely cemented.

Leave A Comment

You must be logged in to post a comment.