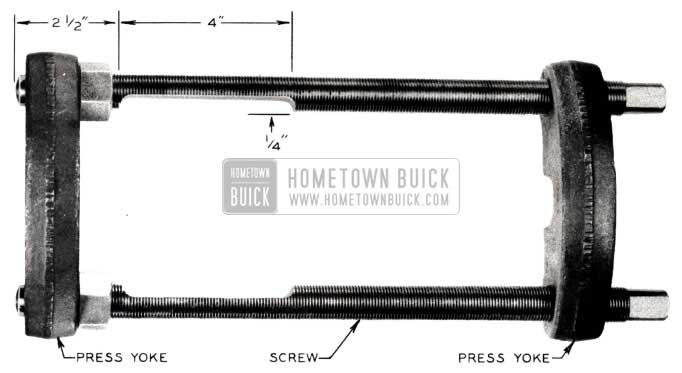

PINION PRESS

The 3.6 rear axle pinion gear will not fit between the screws of theKent-Moorej-1292-Dpinionpress. To overcome this difficulty it is suggested that the two screws be modified as shown in Fig. 247.

1953 Buick Pinion Press

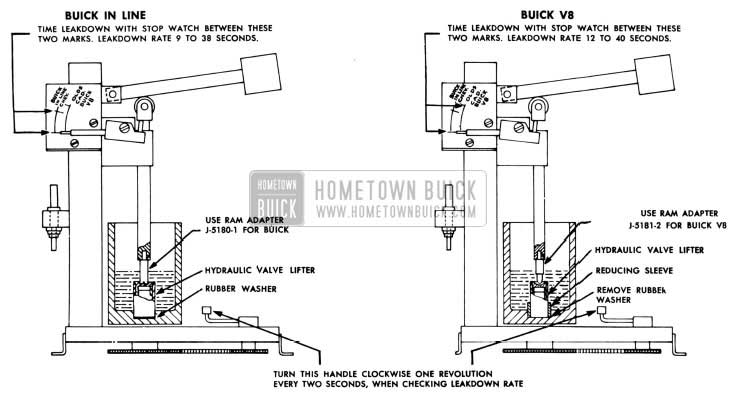

HYDRAULIC VALVE LIFTER TEST

CHECKING LEAKDOWN RATE

BEFORE CHECKING LEAKDOWN RATE, ALL HYDRAULIC VALVE LIFTERS, NEW OR USED, MUST BE DISASSEMBLED AND THOROUGHLY CLEANED TO REMOVE ALL FOREIGN DEPOSITS

Use Fig. 248 as a guide when checking hydraulic valve lifter leakdown rate.

1953 Buick Hydraulic Valve Lifter Test

Fig. 248 illustrates the set-ups that should be used to test Buick Hydraulic Valve Lifters.

Fill the cup with enough clean test oil, to completely cover the lifter. Place the lifter to be tested in the cup with the disc or sleeve as illustrated in Fig. 248. Using the proper adapter position the ram on the lifter.

Pump the arm up and down to remove all air from lifter. When air bubbles are no longer being expelled from the lifter, raise the weighted arm and allow the plunger to rise to its full extended position. Slowly place the arm on the roller and start the leakdown test.

Time the leakdown rate from the time the pointer passes the lower mark until it passes the upper mark on the scale. Be sure you use the proper scale for the lifter being tested.

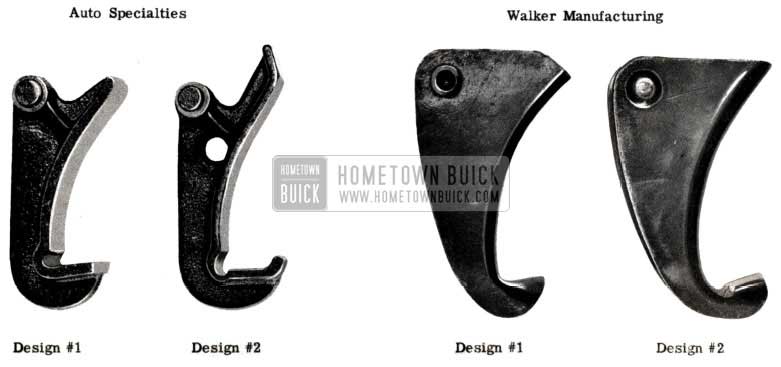

1953 BUICK JACK CAMPAIGN

ALL SERIES

Due to manufacturing variations in the car bumper face plates, the early production Walker and Auto Specialties type jacks cannot be used. Because of their design, the jack load member will not properly secure under the bumper and when jacking up a 1953 Buick will slip off.

1953 Buick Jack Design

Fig. 249 illustrates the original design of the load member or support and the revision made in later production. Fig. 250 is a full view of all three type jacks used in 1953 Buicks and may be used to identify the jacks in the field.

1953 Buick Jack

The early Walker -type jacks were produced on a deviation with a non-removable load member, however this deviation has since been eliminated.

Load members on early production Walker and Auto Specialties type jacks will require replacing to design Number 2 as illustrated in Fig. 249. Auto Specialties replacement load member has been assigned Part No. 1163356, Group No. 8820. The Walker replacement load member Part No. is 1163365, Group No. 8820.

On cars equipped with the deviated Walker jack with the non -removable load member’, it will be necessary to replace the jack assembly in its entirety, Part No. 1391630, Group No. 8820 (less base and wrench handle).

These jack changes are to be campaigned.

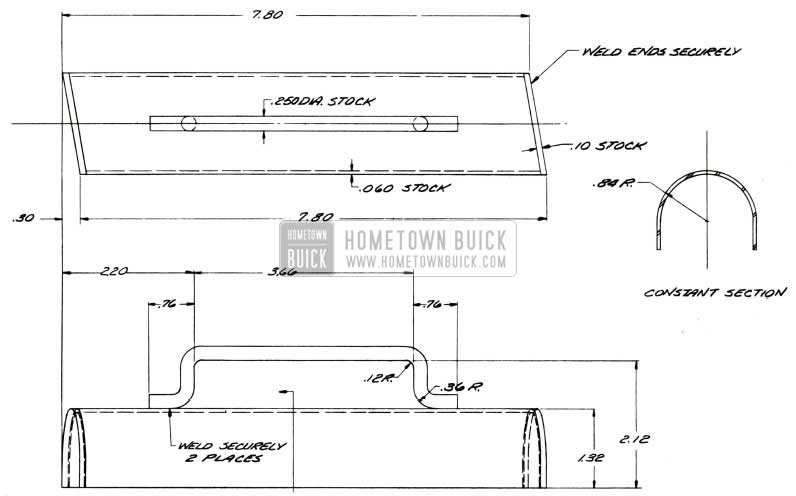

1953 BUICK HOOD SPRING REMOVER & REPLACER TOOL

ALL SERIES

It is realized that a 1953 hood hinge spring tool is needed. Therefore, to save time the following instructions may be used to make a satisfactory tool locally.

CAUTION: THE HOOD SPRING WILL HAVE APPROXIMATELY 400 LBS. TENSIONWHENTHE TOOL IS IN PLACE. EXTREME CAUTION MUST BE EXERCISED WHEN USING THE TOOL AND INSTRUCTIONS FOR ITS MANUFACTURE MUST BE STRICTLY ADHERED TO.

1953 Buick Hood Spring Remover Tool

Fig. 251 gives complete instructions for making the hood spring remover and replacer tool. Make certain that metal thickness, angles and welds are as near perfect as possible. The correct thickness will give the necessary strength. Correct angles on the ends will help to eliminate the possibility of the spring slipping out of the tool. Note that the ends of the tool are welded in place over the end of the sleeve. This design must be followed and the welds must be sound or the tool will not have proper strength.

WHEEL WRENCH

76X – SKYLARK

Because of a production tolerance, some of the wheel bolt and jack handle wrenches (Gr. 5.842, No. 1331 764) used in the 76X Skylark will not fit the wire wheel bolts. The obstruction is the distance from the edge of the wheel bolt to the spoke rim which will not allow the socket to fit onto the bolt head. It is necessary, therefore, to check all 76X wheel bolt and handle wrenches to insure their proper fit over the wheel bolts. If the wrench does not fit, it will be necessary to reduce the outside diameter of the socket end until it slips onto all the wheel bolts. These wrenches are now being ground in production.

Leave A Comment

You must be logged in to post a comment.